I recently enjoyed an ASHRAE young engineers (YEAH!) tour to a DTE cogeneration facility. This appears, to me, to be a state-of-the-art facility which provides power to the Ford Motor Company and sends power back to the grid. A couple of key equipment comments are shared here.

A Great ASHRAE Detroit Young Engineers Tour

The ASHRAE Detroit Chapter young engineers (YEAH!) chairman, Aaron Frantz, arranged a wonderful tour for the February 2023 meeting. The tour of the DTE Vantage Dearborn CEP at the Ford Motor Research and Engineering complex was great.

Full disclosure, I am not a young engineer. I was asked to join in case there were any steam questions system questions that were not being answered. The DTE plant manager, Kevin Siess, did a great job of explaining the plant he is very proud of. There were no questions I had to answer but I am glad I was asked.

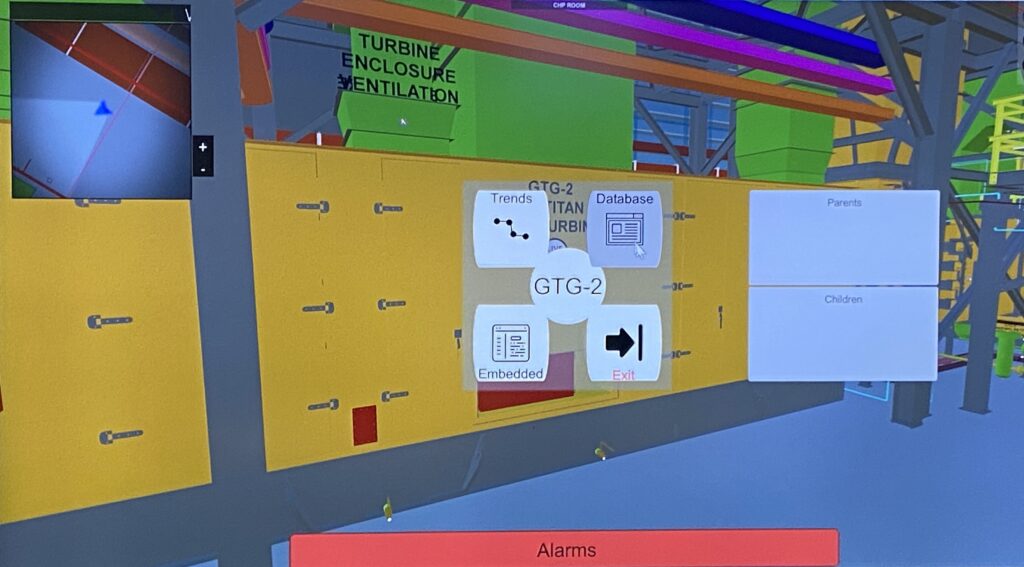

Kevin covered everything as we visited this cogeneration facility. I was impressed by the technology used for status and predictive issues. The night shift was operated by a single person with interactive screens and alerts downloaded to his or her mobile device. Quite impressive for a 34 MW cogeneration plant.

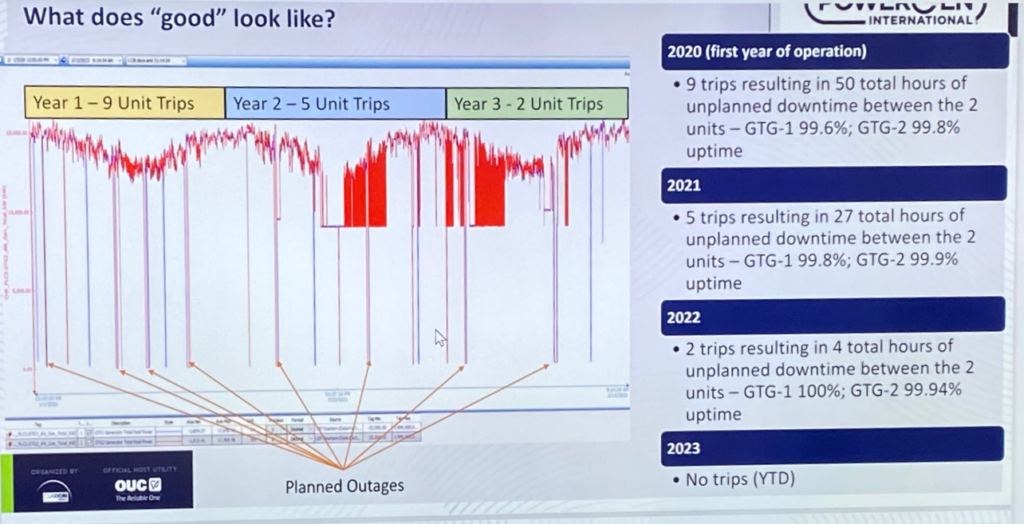

Kevin was very proud of the limited downtime he tracks and reports. Much of the first couple of years downtime was part of commissioning the new plant. The plant is operating for the Ford Motor use and sending substantial amounts of power back to the grid to help relieve other stations. The plant had no unscheduled downtime in 2023 as of our visit.

The two-hour tour was a fast-paced look at an operating cogeneration plant. We got to hear about the installed products we provided on the project which I will selfishly mention here.

There were many applications using Bell & Gossett products. The cooling system uses Bell & Gossett vertical split case pumps. Since the plant is mounted on mother earth, there are no vibration eliminator pads under these pumps.

The cogeneration plant requires water. The proper water pressure can be critical to a variety of areas in the plant. The Ford Motor research and engineering campus has a wildly varying plumbing load. The range from low flow to full demand has a large effect on the water pressure. The CEP also has a varying load. The Bell & Gossett Technologic pressure booster is up to the task of providing constant water pressure with varying suction pressure and varying building loads.

Cooling towers are critical to the operation of the plant. Kevin mentioned the Tower Tech cooling towers and the energy saved by the multiple staged variable speed tower fans. The smaller horsepower fans stage easily and efficiently. They are also easier to work on.

The Tower tech cooling towers not only save energy. The Tower Tech products save water. Kevin mentioned the higher cycles of concentration with the towers. There is also less drift with this design.

Tower Tech also contributes to saving lives. The unique low water storage volume reduced stagnant areas, and elimination of the large tower pan reduces the growth of harmful bacteria. The low drift also reduces the spray around the towers.

It is no wonder that DTE chose Tower Tech for saving energy, saving water, and saving people from illness. Contact us if you want more information and example of how these fine products will help in your application.

Of course, I was also interested in the steam systems. Kevin pointed out the use of disc traps for the high-pressure condensate drips and that drew some questioning looks from the young engineers. More about that in the next R. L. Deppmann Monday Morning Minutes.