The ASHRAE young engineers saw a lot of steam in the recent tour of the DTE Vantage Dearborn Central Energy Plant. The plant manager pointed out the high-pressure drip traps and some of the engineers were puzzled. They expected to see a traditional bucket-style trap but instead, they saw a disc trap. What is a disc trap? Why and when would you use a disc trap? This is the topic of this week’s R. L. Deppmann Monday Morning Minutes.

The ASHRAE young engineers saw a lot of steam in the recent tour of the DTE Vantage Dearborn Central Energy Plant. The plant manager pointed out the high-pressure drip traps and some of the engineers were puzzled. They expected to see a traditional bucket-style trap but instead, they saw a disc trap. What is a disc trap? Why and when would you use a disc trap? This is the topic of this week’s R. L. Deppmann Monday Morning Minutes.

What is a Hoffman Thermodisc Steam Trap?

A disc trap is a type of steam trap. The trap is normally a small inline stainless steel fixed orifice device. There is a small disk at the top of the trap near the cap. It is free to move up and down and not attached to anything. It is the only moving part of the trap. The trap is an on-off constant flow steam trap with no modulating capabilities.

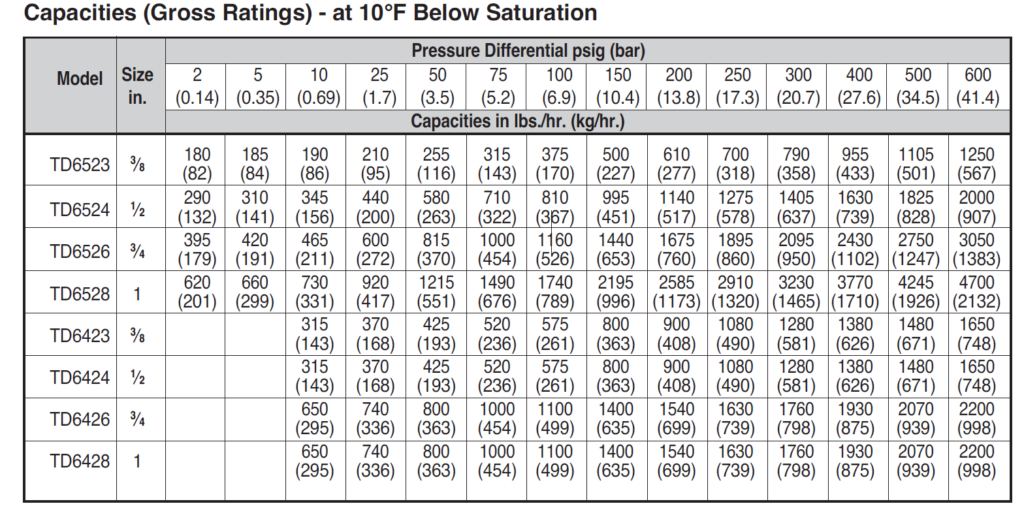

Here is an example of capacities for the Xylem Hoffman (Bell & Gossett) Thermodisc trap.

How Does a Disc Trap Work?

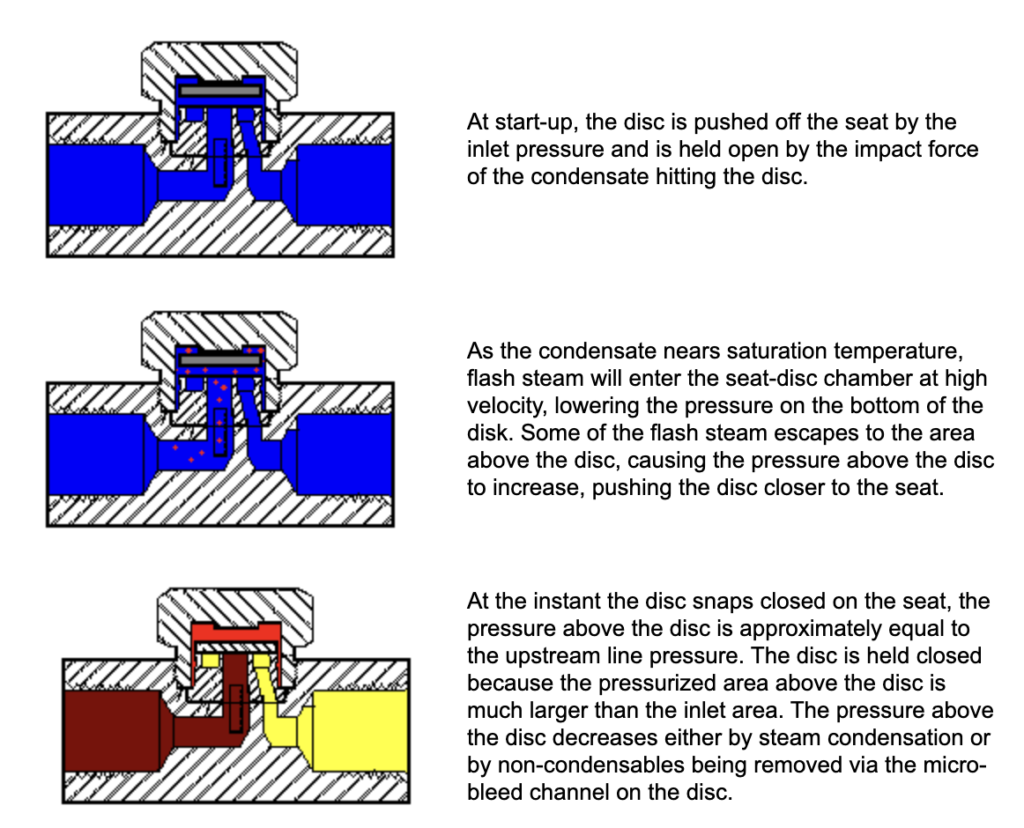

How does a disc trap operate? There is a great description from the Xylem website.

This style of trap will open and close as the disc moves up and down. There is a metal-to-metal contact, and it makes a clicking noise. Some plant managers will say that is how they know it is working properly.

The Best Applications for Disc Traps

Thermodisc steam traps are normally available for smaller pipe sizes. If you look at the capacity chart above, you will see a size range of 3/8” to 1” pipe size. The capacities are very small in low-pressure applications. They are mechanically simple devices with one moving part. That makes them easier to service than a bucket trap.

Where should you use them?

- You will normally use this trap in medium to high-pressure applications.

- They are great for outdoor applications where freezing may occur. Tank plants and tracer lines.

- They work great for high-pressure drip lines to a high-pressure return. Do not use them as drip traps to low-pressure returns. They discharge saturated temperature condensate and some live steam.

- Process applications with on-off steam loads. Superheated steam.

Where should you not use them?

- The trap does not modulate. I would not recommend using this style of trap on a service with modulating control valves.

- Avoid using them on high-pressure drips that are close to the mechanical condensate return pumping units. The excessive steam can cause hammer.

- Applications where the steam is dirty, or noise is an issue.

In the HVAC industry, we normally default to bucket traps as high-pressure drip traps. That made the disc traps at the DTE plant unusual for some of the engineers. Hopefully, this quick blog has helped explain the advantages and applications of the Hoffman Thermodisc steam trap.