HVAC and Plumbing Engineers are discussing more decarbonization and electrification of systems with their clients. The use of electric boilers vs. gas fired condensing boilers is top of mind. Other than State and local construction and energy codes, what does the engineer need to know about the use of electric boilers? R. L. Deppmann’s Monday Morning Minutes offers ten things you should know.

HVAC and Plumbing Engineers are discussing more decarbonization and electrification of systems with their clients. The use of electric boilers vs. gas fired condensing boilers is top of mind. Other than State and local construction and energy codes, what does the engineer need to know about the use of electric boilers? R. L. Deppmann’s Monday Morning Minutes offers ten things you should know.

#1: Efficiency of Electric Boilers

The world of gas fired condensing boilers is all about efficiency. Lower return temperatures and high burner turndown increases the efficiency of those carbon emitting hydronic boilers. Often electric devices are assumed to be 100% efficient. Most boiler manufacturer’s literature will show a conversion from BTUH or MBH to KW. These charts tend to show 100% efficiency.

They are very efficient but 100% may be a stretch. There is some loss through the insulation to the surrounding air. There is also some energy required to heat the metal elements and the boiler itself.

A suitable number to use would be 96%. A specific hydronic boiler manufacturer may have a higher efficiency, but they are normally between 95% and 97%.

#2: Conversion of BTUH to KW for the Boiler Size

I know this is just math but here is a quick conversion calculator. 1 KW is about equal to 3412 BTU/HR. The calculator below is exact.

#3: The Heating Element Size and Materials

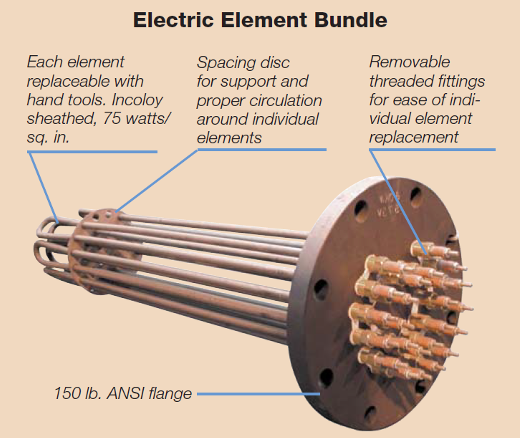

There are several things to understand about the electric elements in a hydronic boiler. The elements must be field removable and replaceable. As time goes on there will be an element failure. Most traditional manufacturers of electric boilers have this feature.

Most manufacturers will use heating elements sheathed in Incoloy 800 material. This material holds up well and protects the element against corrosion while keeping the costs reasonable.

If you look at the photo above, you see a typical heating element. The surface of the heating element is extremely hot and is surrounded by the water you are heating. The chemicals in the water will attempt to precipitate out and coat the element. Small heating areas with large wattage will cause the coating to occur faster than larger surfaces with less heat energy.

Think of a small element compared with a larger, longer one. If they both produce the same watts or heat output, the smaller element will have to be hotter. The small element will burn out faster.

The watts being used divided by the element’s surface area is the “Watt density.” We recommend that you specify a watt density of 75 watts per square inch or less. Many manufacturers adhere to this recommendation for longer trouble-free element life. Some manufacturers offer an alternate option of 50 watts/sq. in. We do not have any data to confirm the additional life of the elements vs. the cost adder. We would specify the 75 watts/sq. in.

#4: Element Control and Staging

The control algorithm of the boiler provides the modulation required for what gas fired appliances refer to as “boiler turndown.” In electric boilers, the elements are staged on and off to maintain the required temperature. This is called stepped control.

The controller should also change the order that the elements are activated so there is equal wear. This staging control should be a part of the boiler specification and is an option for some boilers.

#5: Package Product Disconnect Specification

It is not unusual for engineers to specify packaged equipment with a mounted and pre-wired electrical disconnect. A word of caution about electric boilers. The electric boiler capacity ranges we see in institutional and commercial buildings will normally require three phase power at 208 or 240 or 480 volts in the United States. Depending on the boiler plant size they will require hundreds, if not thousands of amps.

The disconnect when packaged on the boiler could double the size of the boiler. This will limit where the boilers are located, and the space required. Make sure you discuss this with the electrical engineer on the project before defaulting to standard packaged specifications.

Stay tuned! Next week we will cover Commercial Electric Boilers facts #6 – 10.

We will see you back here next Monday for Part Two!