Primary-Secondary vs. Primary-Variable hydronic boiler pumping systems each have advantages for the engineer to consider. Most people in the industry are in one camp or the other. Since I am a Bell & Gossett pump representative, I have always joked that more pumps purchased for a project must be better. 🙂 What are the reasons to use one system or the other? That is the subject of today’s R. L. Deppmann Monday Morning Minutes.

Primary-Secondary vs. Primary-Variable hydronic boiler pumping systems each have advantages for the engineer to consider. Most people in the industry are in one camp or the other. Since I am a Bell & Gossett pump representative, I have always joked that more pumps purchased for a project must be better. 🙂 What are the reasons to use one system or the other? That is the subject of today’s R. L. Deppmann Monday Morning Minutes.

Primary-Secondary vs Primary Variable

I joke about purchasing more pumps but that is a key difference between the two systems. The primary secondary piping system will require the extra primary pumps on the boilers with their control, electrical, and installation costs. The owner will have a couple of extra pieces of equipment to maintain.

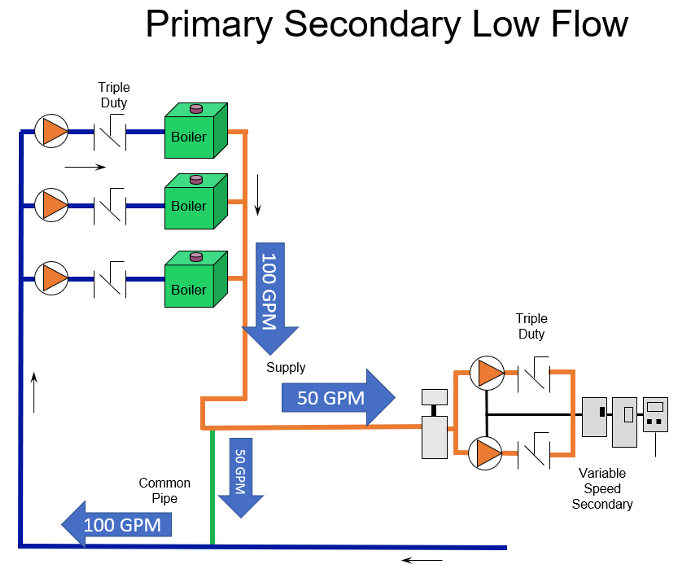

Another difference is all about matching the flow rates. The primary variable system clearly will have the same flow rate through the system and the operating boilers. In the primary-secondary system there is a common pipe. When properly installed, this common pipe will allow the flow to change in one system without affecting the flow in the other system. The flow rate may be different through the boilers and the secondary system. This will cause the issue of mixing through the common pipe which I address later.

In primary variable pumping systems, the boiler and piping pressure drop is added to the main system pumps. We are still paying for the energy to overcome the pressure drop of the boiler. There may be a little better efficiency in the base mounted system pumps then the inline boiler pumps. Even if the inline boiler pumps have ECM motors, the overall pumping energy may be less in a primary-variable system. The primary variable system should have on-off automatic valves at each boiler, so we do not flow water through a boiler that is off. These are just motorized butterfly valves so there is some pressure drop but normally it is small.

These are the key differences. The challenge is all about the boiler you choose and whether the manufacturer prefers primary-secondary over primary variable.

Primary-Secondary Boiler Pumping Systems; It is All About the Boiler.

Why would a boiler require primary secondary piping? There are three main reasons. The boiler cannot handle the potential minimum flow rate which the system two-way valves may provide. The boiler is not designed to match system designs with temperature difference greater than 30 or 40 degrees. The boiler controls cannot adjust the burner fast enough to match the system demands.

Flow Rate Boiler Issues

One of the key purposes of primary-secondary piping is the protection of one zone from changes in flow in the other zone. Engineers who design HVAC and plumbing systems are aware of the use in chilled water systems. The chillers cannot manage too low a flow rate which occurs in the two-way controlled secondary system. To protect the chillers, primary secondary piping is used. Some boilers have the same issue.

If the system can turn down to a low percentage of the design flow rate but the boiler cannot, the manufacturer will require primary-secondary piping. This piping method will allow a primary pump to operate at the flow rate required by the boiler regardless of the system flow rate. The primary loop may employ a variable speed primary pump. This will allow the flow rate through the boiler to drop to a minimum allowed by the boiler manufacturer.

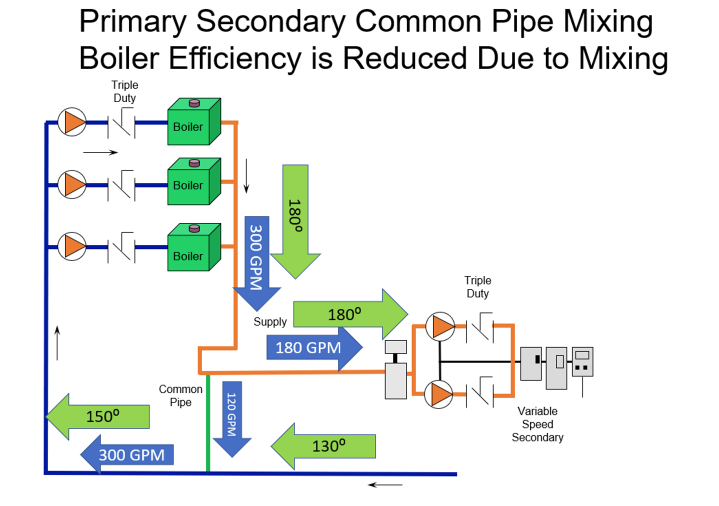

If the system flow rate is less than the boiler flow rate, there will be flow bypassed through the common pipe and mixed with return water. There is some inefficiency in this extra flow rate being bypassed. The mixing of the system return water with the system supply water will raise the return water temperature to the boiler which will decrease the efficiency of the boiler plant.

Variable speed primary pumps: Some boilers will use a variable speed ECM pump in lieu of a constant speed pump boiler pump. This is referred to as “variable primary-variable secondary.” The boiler manufacturer will adjust the speed of the pump to try to match the load required. This will produce less flow rate in the common bypass pipe as long as the flow rate is within the limited turndown of the ECM pumps.

Delta T Boiler Issues:

Limited temperature rise is another reason primary-secondary exists. The temperature difference in the system are different than the temperature difference of the boiler. If the system has a fifty-degree delta T at design but the boiler can only manage a thirty-degree temperature difference, the boiler manufacturer will require primary secondary piping.

The boiler will bypass a portion of the hot water produced back to the return. This higher temperature water will mix with the lower temperature system return water to provide the required boiler temperature difference.

Primary Variable Boiler Pumping Systems: It is All About the System

In the previous section, the engineer is adapting the system piping to accommodate the boiler limitations. What happens if the engineer selects the system design requirements and then selects the boiler to match the design? Now you will be able to use primary variable pumping.

The primary variable system will have a minimum flow rate required for the pump. The system will require some means, such as a few three-way control valves, to protect the pump from operation below this minimum flow rate. Now the engineer can check that flow rate against the minimum boiler flow rate.

The engineer may be designing the system for a larger delta T to increase the boiler plant efficiency. Verify the boiler plant can manage the same delta T.

These two simple steps will determine whether the design will require primary-secondary or primary variable pumping.

I have not mentioned system turndown matched with boiler turndown. That will be a later R.L. Deppmann Monday Morning Minutes.