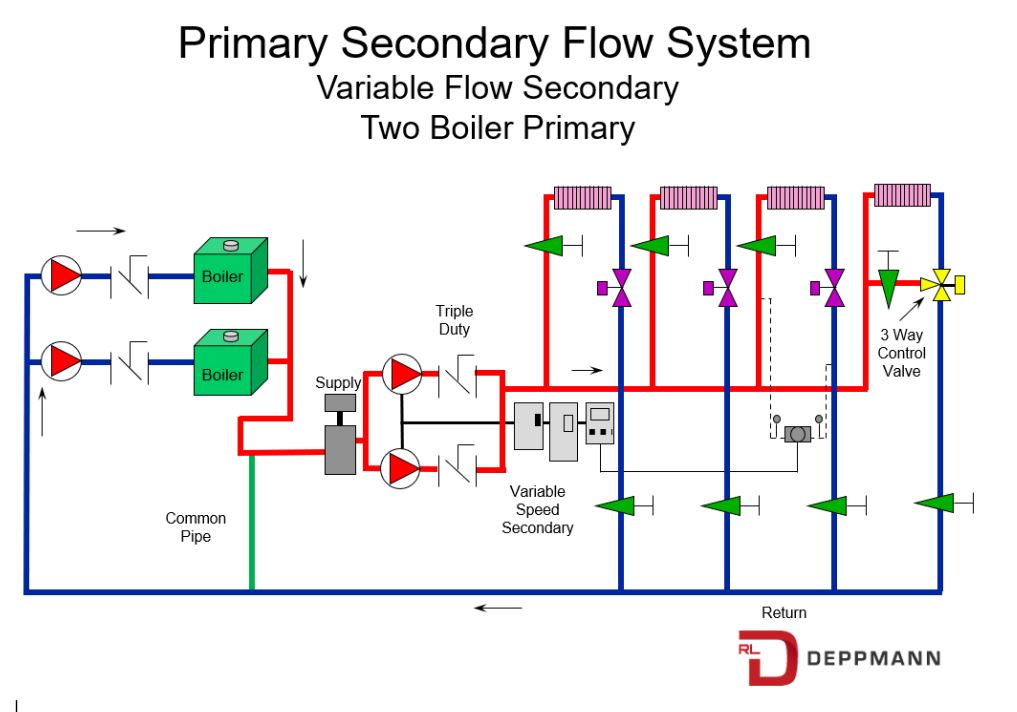

Many boilers manufacturers recommend or suggest using a primary secondary arrangement rather than primary variable pumping. Often this piping scheme is suggested to avoid flow rates that may cause nuisance shutdowns due to improper operating conditions. So, flow rate is important. How does the primary secondary common pipe pressure drop affect the boiler flow rate?

Primary Secondary Common Pipe Length

In the previous Monday Morning Minutes, Primary Secondary Piping Basics: Part 2 – The Common Pipe, we described the traditional “purest” piping of the common pipe as two straight through tees and one foot of pipe. Many times, the engineer does not show all the pipes coming into a tight bridge configuration. The drawings will show piping like the sketch below and the common pipe may be much longer than the one foot shown in textbooks.

We know from part 2 of the blog that the reason for the short common pipe with very small pressure drop was to avoid gravity circulation and overheating. Is there a concern with boiler primary secondary loops? Read on and we will look at an example.

Primary Secondary Pump Selection Example

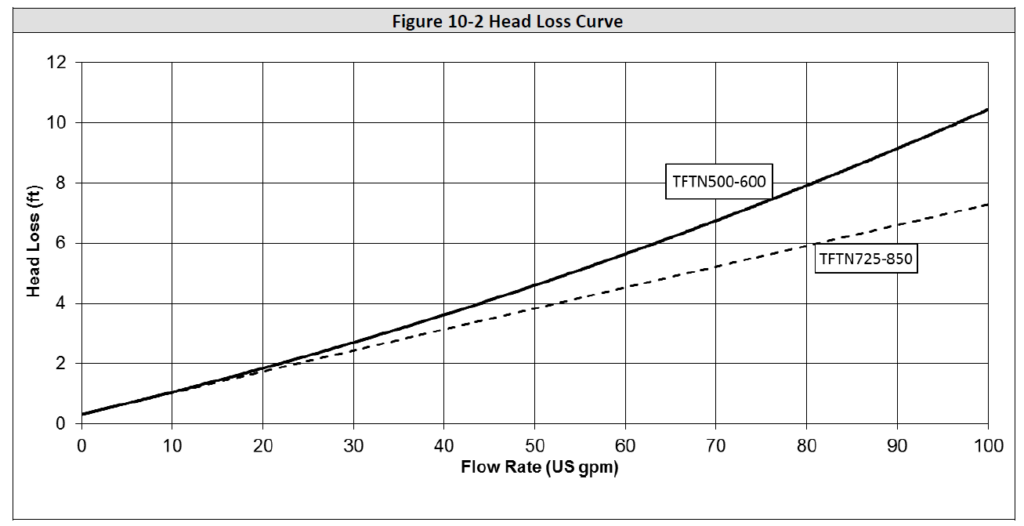

For our example let’s use the fire tube NTI Boilers TFTN510 boiler series we introduced in Condensing Fire-tube Boiler Heating Systems: Primary-Secondary Pumping. We will assume the system has one of these boilers operating and one expected to be on standby. If we use the same 30°F ΔT as shown in the referred blog, the flow rate at full fire in a non-condensing mode of 150°F return will be 34 GPM for each boiler.

Remember, I said not to assume what one person is calling the loops. We will call the boiler loop the primary. The coil or system loop will be called the secondary. The pumps will have a head based on the very short piping to and from the boilers, the fittings, the check/balance valve, the common pipe, and the boilers. Fire tube boilers have rather small pressure drops compared with water tube boilers. In this case the pressure drop at 34 GPM is only 3 feet.

Let’s say the engineer chose a pump for 34 GPM at 10 feet. It is probably very safe, but the balance valve can take up the extra pressure drop. The engineer selected a B&G model PL-75 maintenance-free circulator with a 1/6 HP 115/60/1 motor.

Caution About Boiler Manufacturer’s Requirements for Piping

We always want to make sure we are designing a piping system that follows any manufacturers’ recommendations. I’m going to talk about straying from traditional common pipe lengths. That said, if the boiler manufacturer says two tees and a maximum of 5 feet of pipe, that is what must happen regardless of what we describe below.

Effect of the Common Pipe Pressure Drop on The Primary Loop

In our example system with a short common pipe, this would result in 0.12 feet of common pressure drop. It would cause 1.2 GPM of flow in the primary loop standby boiler if the secondary was at 34 GPM and the boiler pump was off. Not a lot of flow rate. This small flow rate could be eliminated if there were B&G Flo-control, weighted anti-gravity valves or properly designed spring-loaded check valves as described in the link above. Either way there is not much effect.

What if the common pipe was longer and had much more pressure drop? Let’s say the common pipe had 3 feet of the 10 feet of head.

- With 34 GPM in the common pipe secondary and with the boiler pumps off, there will be about 18 GPM flowing through the off boilers and pumps. It is possible to get enough flow through the pump that it starts to spin the impeller. Now it is in the same direction as the flow would normally be, so it is not as bad as an impeller spinning backwards. Just the same, there may be some premature coupler failure if this is continuous. But when would you have full flow in the secondary and have the boiler pumps off?

- If there are multiple boilers with one on and one off and the secondary flow rate exceeds the operating boiler’s flow, there will be some flow in the off boiler(s). This will cause mixing of the supply water to the system supply.

- As the primary or secondary flow through the common pipe changes, that will change the boiler flow rate. If the common pressure drop is reasonable, it should not be a dramatic flow rate change.

How Much Pressure Drop Can I Stand in a Boiler Loop Common Pipe?

This is a question we often hear from engineers and contractors. Do I have to make the common pipe one foot long? What if it is longer? What if there are a few tees in the common pipe? What if, what if, and what if. Here is my “go to” for comfort in answering this question.

In a primary secondary boiler loop we are not worried about overheating a coil since the boiler is the heat source. We do have to be careful about minimum flow and maximum flow in the boiler. The pressure drop in the common pipe from design secondary flow rate to zero secondary flow rate will cause a change in the pump GPM. I am comfortable with common pipe pressure drops all the way up to 4 feet as long as two conditions are met.

- There is a properly installed spring-loaded check valve with a pressure required to open the check. This pressure drop is 1-1.5 feet normally.

- The engineer figured out the pressure drop in the calculations.

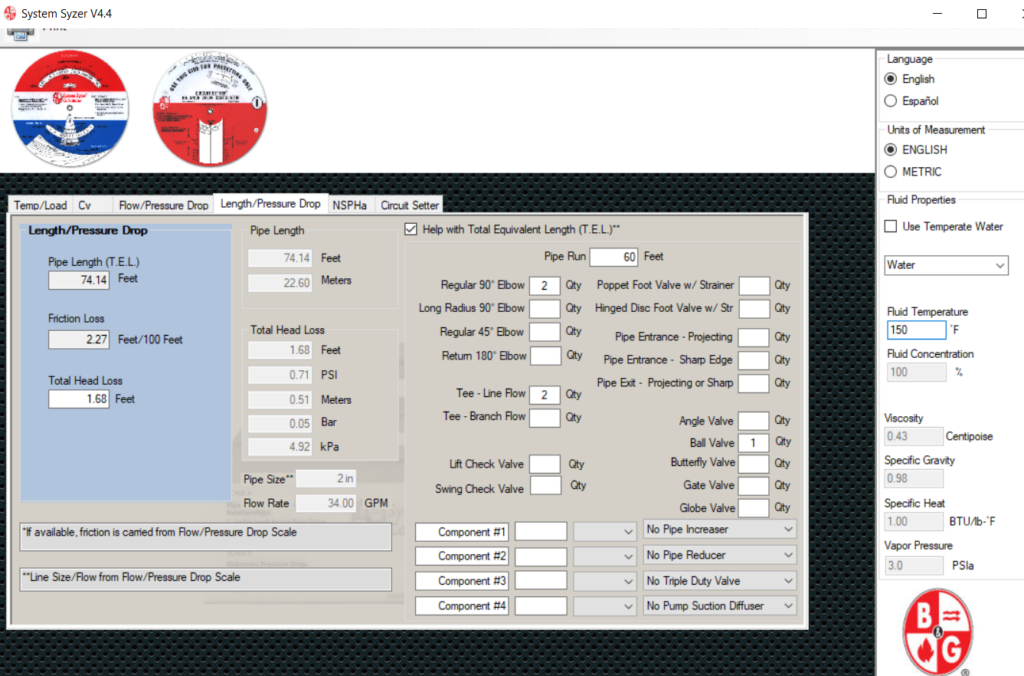

In our example, what if I used 2” copper pipe and made the common pipe 60 feet long and added two elbows and a ball valve to that pipe. Using the B&G system syzer, the answer shown is 1.68 feet. It will cause a difference, but not much difference.

So, in boiler loops, I suggest keeping the common pipe pressure drop under 4.0 feet.

Part 1: Primary Secondary Piping Basics: Part 1 – Terms

Part 2: The Common Pipe (also Referred to as the Decoupler)

One of our Monday Morning Minute readers has brought to our attention a needed correction in the last Monday morning minutes: The Common Pipe (also Referred to as the Decoupler).

One of the primary secondary coil diagrams showed a three way for minimum flow protection but left off the bypass pipe. We have corrected it in the article.

We thank Ted Tracewicz of Mississauga, Ontario for finding the error.