Shell and Tube heat exchangers are often used in institutional steam-to-water heating applications. This week’s Monday Morning Minutes post looks at minimum velocities in Bell & Gossett SU heat exchangers applied to a variable volume, variable speed system.

In part one of this series, we discussed maximum velocity in Bell & Gossett SU heat exchangers with standard tubes applied to a variable volume, variable speed systems. We also gave some recommendations. Just because we can operate at the edge of the maximum velocity does not mean we should. Today we look at minimum velocity in heat exchangers.

Minimum Water Velocity in Shell and Tube Heat Exchangers

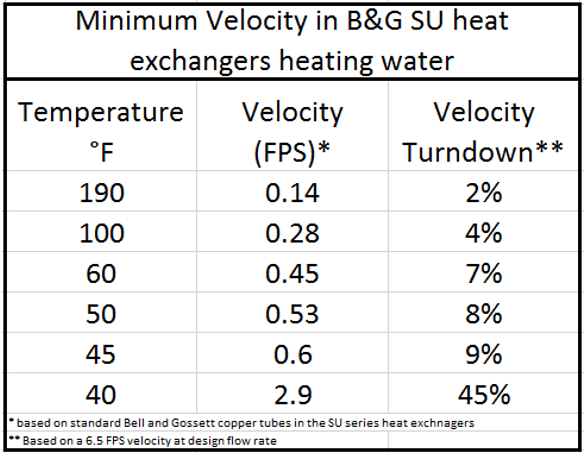

As two-way valves close in hydronic systems, the velocity in a primary variable shell and tube heat exchanger will drop as the flow rate drops. How far can the flow rate drop and still have turbulent flow? Let’s start with a quick review of why turbulent flow is important.

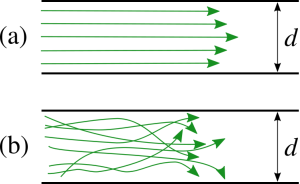

In shell and tube heat exchangers, as with other heat transfer devices, turbulent flow (b) is constantly mixing the water in the tubes, so that all of the droplets of water have the chance to contact the hot tube wall. As the velocity drops, the flow pattern will change to laminar flow (a). In laminar flow, the flow pattern straightens out and some of the water on the inside of the tube does not contact the tube wall and therefore remains cooler. In other words, in laminar flow, there is less heat transfer.

(a) Laminar flow (b) Turbulent flow

The concern is that the temperature control valve will start opening more, then overshoot, then close, then open. It will act more like an on-off valve than a modulating valve. Is this really a concern we need to worry about?

Water is a great heat transfer fluid. In the world of hydronic heating fluid mechanics at lower velocities, the Reymolds number (Re) remains high enough and the Prandtl number (Pr) remains low enough that low velocity is not an issue. In most heating applications, the flow rate has to drop down to below 5% of the design before there is an issue.

In most heating applications with water above 50°F, there are other devices such as pumps that have higher minimum flow requirements than the heat exchanger. The concern about cycling the control valve will have more to do with the control valve turndown than the heat exchanger.

But the story changes when using glycols as the heat transfer fluid.