Centrifugal pumps in hydronic systems normally have flexible connectors on the inlet and outlet piping at the pump. Why are they there? Do we need them? What is the advantage and disadvantage of one over the other? Today, R. L. Deppmann Monday Morning Minutes looks at pump flexible connectors.

Before we start, R. L. Deppmann is the representative for Xylem Bell & Gossett and Metraflex in Michigan and Northern Ohio. We will be using examples from those manufacturers.

What is a Flexible Connector?

Don’t you love our industry marketing terms? As engineers we “cut to the chase” and call things exactly what they do. An expansion tank is simply a tank that takes up expansion. A check valve is a valve that checks flow. A flexible connector is a connector that is flexible.

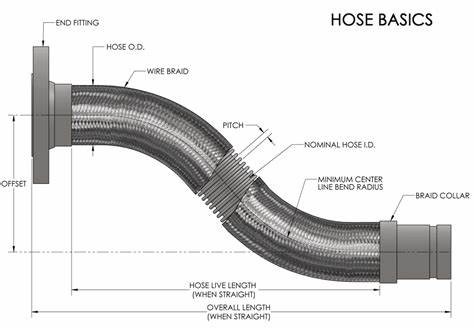

A flexible connector is a product that mounts between a piece of equipment and the pipe attached to it. Its purpose is to move. This device may be able to adjust for limited piping misalignment between the piece of equipment and the pipe, expand and contract, dampen vibration, and reduce noise. We will look at these four items in this blog as well as differences between stainless steel and rubber flex connectors.

Piping Misalignment

Pump manufacturers provide IOM manuals for proper installation of the pumps. Bell & Gossett, for example, requires the base mounted pump be leveled to the housekeeping pad or vibration base and that no stress be placed on the pump flanges. Many headers are prefabricated and brought to the jobsite, hung, and the pipe is brought down to the pumps. There is a chance that the pump flanges and the pipe flanges may be misaligned. If the contractor “springs” the pipe to the pump, there will be substantial stress on the pump flange. This would cause vibration and premature failure of pump parts. Enter the flexible connector.

The standard stocked flexible connector may offer a maximum permanent offset of 1/8” up to 1” or so. It allows a “small amount of lateral misalignment to be managed.”

Expansion and Contraction

As temperatures change in the hydronic system, the pipe expands and contracts. The engineer will design bends in the piping to accept the movement. If the bends cannot manage the movement, the engineer will select expansion joints. Note that flexible connectors are not expansion joints.

Some flexible connectors can contract and expand a little. You should not count on stainless steel braided flexible connectors for any expansion or contraction. Rubber connectors may have limited ability to expand and contract. The Metraflex Cablesphere has movement in all directions.

Example: Say there are 15 feet of pipe and valves on the discharge of an end suction pump before it gets to the header. Assume the application is a heating system designed for 180⁰F and started when the room, pipe, and water was 70⁰F. We use the chart shown in Expansion Joints for HVAC Steam Systems and see the expansion is 1.37-0.53 = 0.84 inches per 100 feet. That means the pipe will grow about 1/8” in the 15 feet to the header. The hanger better be able to move! If the header is secured to the building and pump is secured to the floor, all the movement will attempt to be at the flex connector. The rubber connector can manage it. The stainless connector cannot expand and contract without damage.

Noise and Vibration

Noise and vibration are a concern in every installation. A rubber connector can attenuate some while a stainless connector will not. There is a great article by Marty Rogin for further review at pumpsandsystems.com titled Isolation of Noise & Vibration in HVAC & Plumbing Piping Systems or contact your Metraflex sales person.

The bottom line is for reduction in noise and vibration, use a rubber flex connector.

Rubber vs. Stainless Braided Flex Connectors: Which Should I Use?

We have written about this subject in the past and we share the links below. We can make some general statements contained in the articles. More information is available from your Metraflex sales representative.

Stainless Steel Braided Flex Connectors:

- Most work to high pressures and a vacuum.

- In general, they are more rugged than rubber connectors.

- In general, they last longer than rubber connectors.

- They tend to be less expensive.

- They do not expand and contract.

- They do not do a good job of sound and vibration attenuation.

Rubber Flex Connectors:

- Must watch maximum pressures including any test pressures on the job.

- Most are not acceptable under vacuum applications.

- Must be installed between flanges if flanged.

- They have a limited life expectancy of about 5 to 30 years. Owners should check their condition regularly and particularly after 5 years.

- They tend to be more expensive.

- They can move in all directions.

- They do a decent job of sound and vibration attenuation.

Visit these previous blogs for information:

- Why Use Flexible Connectors in Hydronic Pump Piping and Trim

- Hydronic Pump Piping and Trim: Stainless Steel Flexible Connector?

- Hydronic Pump Piping and Trim: Rubber Flexible Connectors