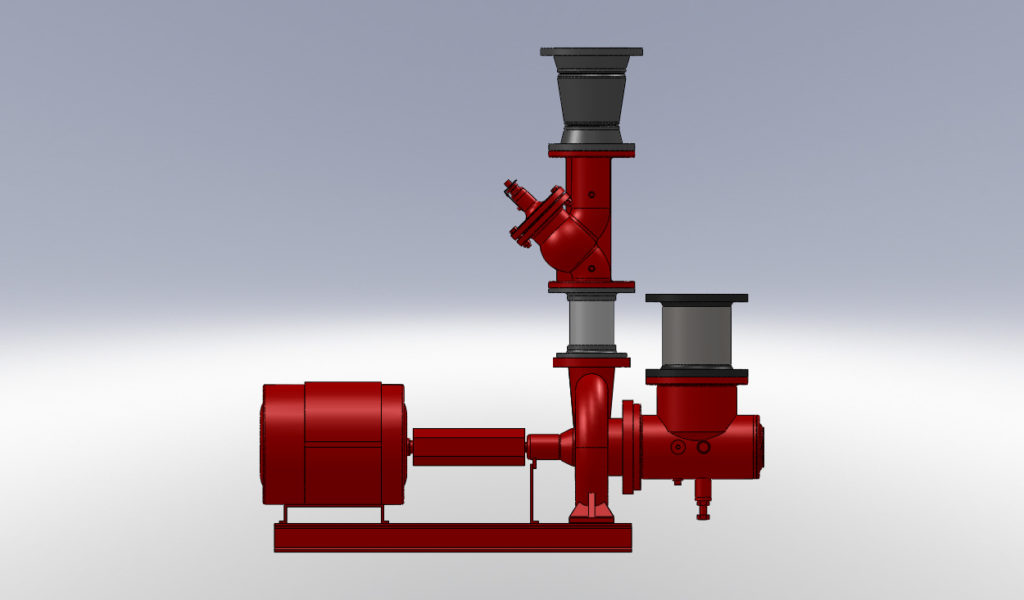

The R. L. Deppmann Monday Morning Minutes will look at near pump piping over the next several weeks. This week, we want to spend some time on the flexible connectors used on hydronic pumps.

Flexible connectors and their use on pumps are often a misunderstood product application. We regularly get calls from engineers and contractors about the proper connector to use on pumps.

Why are flexible connectors provided on hydronic pumps?

Flexible connectors are often specified for both base mounted and inline pumps. What is the purpose of using flexible connectors? Other than “I’ve always used them.” Flexible connectors may serve several purposes today. Depending on the type of connector specified, they will:

- adjust for minimal misalignment in the piping system

- accommodate some misalignment due to thermal expansion/contraction

- absorb some noise

- absorb some vibration

Pump connectors are really only needed if there is a vibration base under the pump. There are plenty of installations of pumps with no flexible connectors and no problems. It all gets down to precise piping of the pump and piping. When the pump flange and the pipe flange are perfectly aligned, with no horizontal or vertical strain, the pump will be happy. When the piping design allows for expansion and contraction, with no strain on the pump flange, the pump will be happy. This perfect installation can be difficult to achieve, so many engineers specify the use of flexible connectors.

Flexible Pump Connectors Used for Minimal Misalignment

Every pump manufacturer provides an installation, operation, and maintenance manual (IOM) which specifically identifies the issue of causing strain on the pump suction and discharge flanges. There are many fine fitters and plumbers who do their very best to align the pump and pipe but still end up with a slight offset. The properly applied flexible connector can adjust for that offset.

Flexible Connectors Used for Thermal Expansion and Contraction

Flexible connectors are not expansion joints. Expansion joints are used to absorb axial movement caused by the pipe expanding and contracting, which ends up pushing away from the anchors. That being said, the pipe always expands when heated and contracts when cooled. The engineer and installing contractor can use elbow turns, offsets, or “Z” piping to create flexing of the pipe during expansion and contraction. If this flexing extends to the pump flange there may be a strain that could cause vibration. If this flexing does occur, a properly applied flexible connector can relieve the stress.

Flexible Connectors Used for Noise and Vibration Control

Flexible connectors can be used to attenuate noise and vibration. The connector can move in the lateral direction which helps absorb vibration. The reality is that metal connectors are less effective for vibration concerns and have no value for noise issues. Elastomer type connectors, often referred to as “rubber” connectors, will help with noise and vibration. I’ll cover this in more detail in a couple of weeks.

Types of Flexible Connectors Used for Hydronic Pumps

Metraflex Company provides a multitude of flexible pipe products. In this article and in the next two weeks, I will limit the discussion to those most commonly used with hydronic pumps. I’ll also make some suggestions about specifications of both metal and rubber connectors in the next R. L. Deppmann Monday Morning Minutes.