Last week, the R. L. Deppmann Monday Morning Minutes introduced reasons why flexible connectors are used on pumps. This week the subject is the stainless steel flexible connector. Next week, I will write about the rubber connector.

One of the main reasons stainless steel flex connectors are so prevalent is that in sizes below 8”, they are the least expensive option. If the engineer did not give any direction in the specification or does not hold to the specification, the price will win out. Let’s look at the advantages and disadvantages of stainless steel connectors.

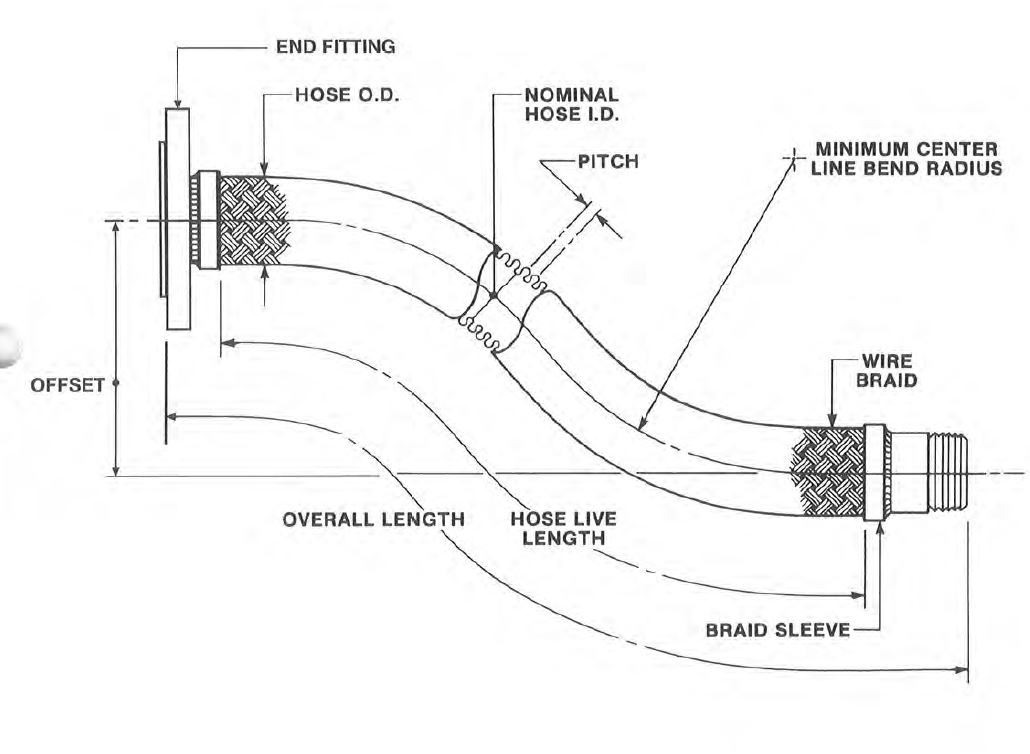

What Are the Parts of a Stainless Steel Flexible Connector?

In general, most stainless steel flex connectors are also called hose and braid type. They have three parts:

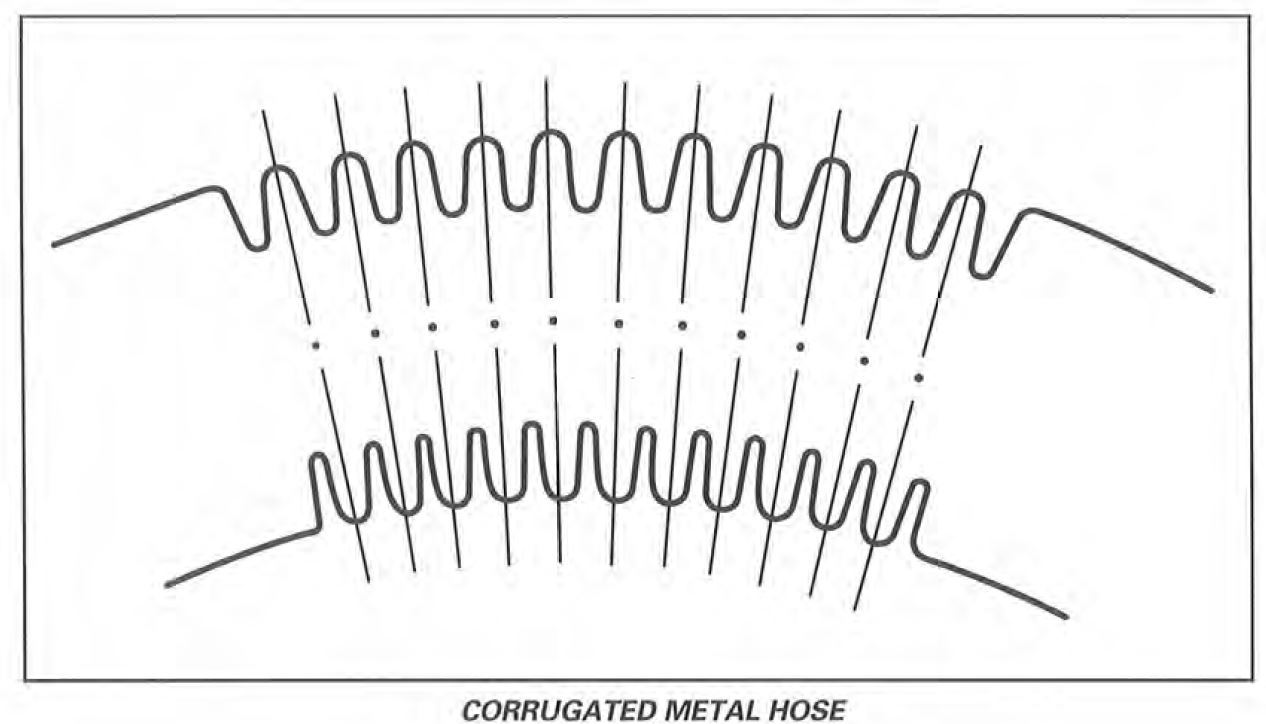

- an internal SS corrugated hose

- an external SS braid

- end connections

The internal corrugated hose is like an accordion. It can move in and out and back and forth. If it is subjected to internal pressure like that in a hydronic system, it will expand and be deformed forever. Thus, the flexible hose must be controlled.

The job of controlling movement is accomplished through an external braid. The braid is literally wiring braided together. This makes a strong support, just like a rope is stronger when the strands are braided together.

The end connections can be flanged, NPT, solder, grooved or other choices to match the piping system.

The following representations are from the Metraflex Hose and Braid Design Guide.

When the stainless steel flexible connector is used for hydronic pumps and other equipment, it is important to know some terminology that will show up in specifications. As mentioned in the previous blog, the main reasons for using these is pipe misalignment, the intermittent offset due to vibration or surges, and constant misalignment caused by expansion of the pipe when heated. These connectors move laterally but not axially. They are NOT expansion joints. The braid that gives them the strength also limits that movement. There are other specific metal bellows and rubber expansion joint products made for that movement.

Lateral and Axial Movement in a Pump Connector

A Metraflex MPTR model is shown above. This is a stainless steel bellow style pump connector. This connector is only 6” overall length (OAL). Because it is made of stainless bellows without the hose and braid, it can move axially. If I look at a model for 6” pipe, it can compress one inch, extend 0.2”, and handle lateral offset of 0.2”. Why do we sell more hose and braid connectors than this one? It cannot handle much offset for misalignment. The installation of this type of product is also more expensive. The Vanstone flanges must sit precisely on a mating flange. I’ll talk more about this next week when the subject is rubber connectors. Besides a higher installation cost, this type costs much more than both the hose and braid connectors and some rubber connectors.

So the real issue when using stainless steel flex connectors on hydronic pumps is first cost vs. required movement. Normally, offset due to misalignment is the real need.

Which Stainless Flexible Pump Connector?

The more live length, the more movement. The more live length, the more expensive the connector. How much do you need? Let’s look at several stainless steel flexible connectors.

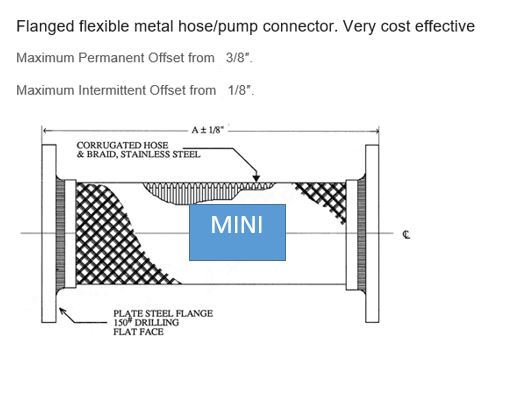

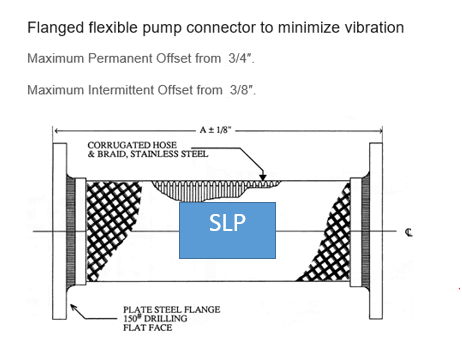

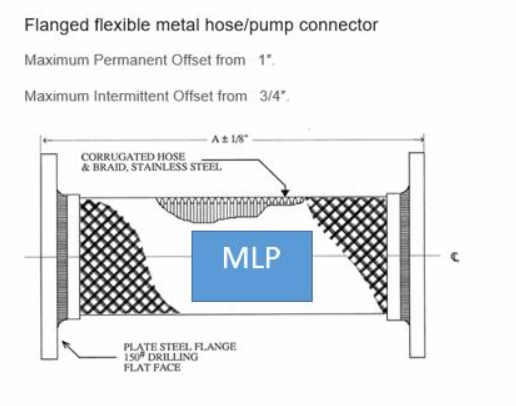

Metraflex manufactures a wide range of flex connectors and expansion compensation products. Here are a few choices we will use to review operation in a 6” size. The least expensive is the Metra-Mini. The 6” connector is 11” overall length (OAL). The SLP is 14” OAL. The MLP is 20” (OAL). The only difference is the OAL which increases the allowable misalignment.

Let’s assume you have 6” steel pipe at 180°F and a starting installed temperature of 40°F. The pipe will expand about one inch per 100 feet. Depending on the length of the riser, horizontal mains, and anchor locations, there could be some lateral movement at the flex connector. The low-cost Mini style connector can only move 1/8” intermittent offset and 3/8” permanent offset. The intermittent movement is smaller because it assumes the movement is cycling or vibrating. This does not occur in centrifugal pumps used in HVAC applications. The permanent offset includes both misalignment and expansion. There is not much movement for piping misalignment and expansion. This small connector works in most applications but if the engineer wants a little more movement, we would suggest the Metraflex SLP. The engineer should always make sure they design with an eye on expansion and movement of the pipe.

When deciding on the specification for flexible pump connectors, make sure you understand the movement you want to standardize on and the cost. A 6” Mini connector might be around $250 while an SLP would be around $500, and a bellows-type mentioned above would be twice as much as the SLP. That being said, the SLP can handle a good amount of movement. If you are using stainless pump connectors and choose the Metraflex SLP or the Mini, there are specifications available for you.

Next week, the subject of the R. L. Deppmann Monday Morning Minutes will be rubber connectors and the advantages and disadvantages over stainless steel connectors.