Steel expands when you heat it. This is a fact of nature and shouldn’t be overlooked when designing the HVAC steam piping system. One way of accommodating the expansion of the pipe is to use an expansion joint. Today, the R. L. Deppmann Monday Morning Minutes offers a solution for steam piping expansion joints.

Expansion of Steel Pipe

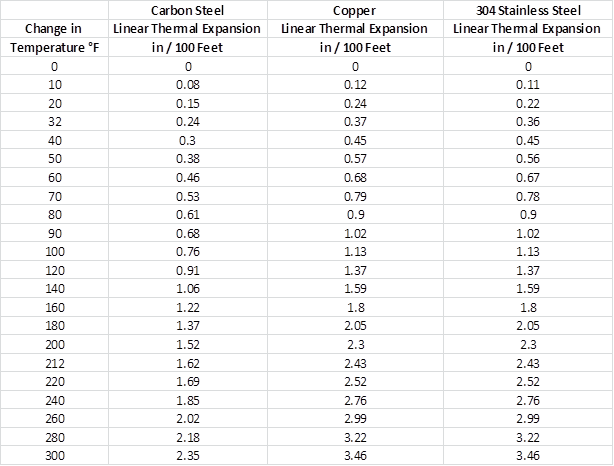

There are many ways to control the expansion of steel pipe in steam distribution systems. One obvious solution often used is the natural flexibility of the pipe by installing a hard-piped expansion loop. Let’s look at a quick example. Let’s assume the project has 50 PSIG saturated steam in a 10” supply pipe which is 150 feet between anchors. The steam temperature is about300°F. If the project is in Michigan and the pipe is 0°F when installed, how much will the pipe expand?

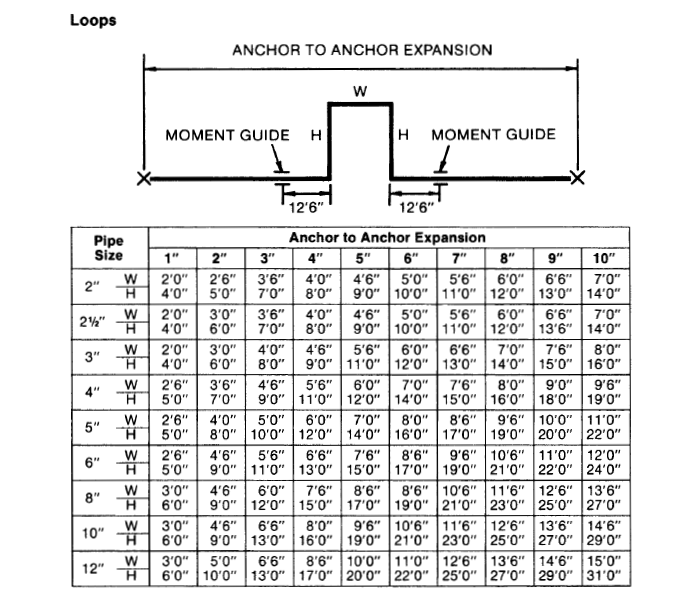

From the chart above, with a 300°F difference, we see that the steel pipe will expand 2.35” per 100 feet or a bit over 3.5” for 150 feet. The engineer may apply a safety factor to the numbers and ask for 4” of expansion in the piping system. Using the chart below from the Metraflex MEJ97 expansion joint guide, the engineer identifies the hard piped expansion loop must be 16’ long by 8 feet wide. Sometimes that required area for the loop or the installed cost becomes a hindrance and the engineer chooses to use an expansion joint.

Why Packed Expansion Joints Should Not Be Used

Many specifications call for “packed type” expansion joints for steam systems. These joints have the ability to absorb large amounts of movement but have a long list of disadvantages. The first is simply the very large anchoring loads. Second, these joints have packing in them and if they are left in a set position for long periods of time, the packing may set up, which results in higher anchor loads and even leaking. Third, they are very expensive. Fourth, and probably the biggest drawback, they require regular maintenance by a knowledgeable service technician or fitter.

If the joint is not maintained or is packed improperly, there may be failures that cause leaks or disasters. Packed joints may have to be used when the steam pressure is very high and space for piping loops is limited but most HVAC applications do not use extremely high pressure steam. When steam pressures are below 300 PSIG, we recommend pack-less, externally pressurized joints.

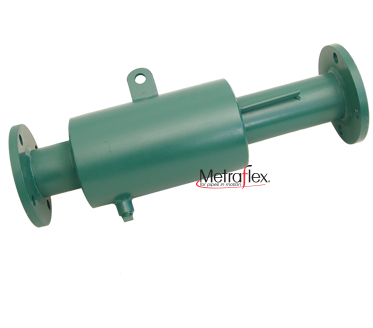

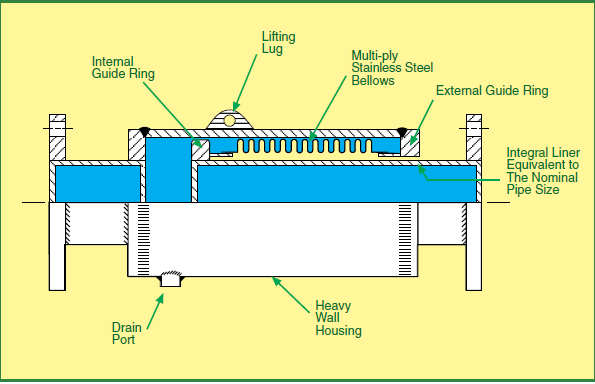

Metragator Externally Pressurized Expansion Joints

The Metraflex Metragator externally pressurized expansion joint provides a great deal of benefit at a reasonable cost. Why use a“Gator” instead of a standard bellows type expansion joint? Bellows joints want to expand outward when pressurized. In steam applications, these joints normally have controlling rings similar to the Metraflex MC Expansion joint. These rings add to the cost of the joint. In addition, the controlling units may be subject to dirt accumulation. There is another concern. The Expansion Joint Manufacturer’s Association publishes a chart showing the maximum velocity in bellows joints without a liner. Steam velocities may be very high and will most definitely require a liner. This liner again adds to the cost.

The Metragator’s sliding externally pressurized construction acts to control the bellows and extend the life of the joint. In addition, the unique sliding pipe design provides the liner so the bellows are not subjected to the erosion of high velocity.

The literature, specifications, Revit files, and IOM are all in one convenient place on the Metraflex website.

As with all expansion joints and loops, proper guiding is required. We have the details regarding proper guiding and can help you with your design.

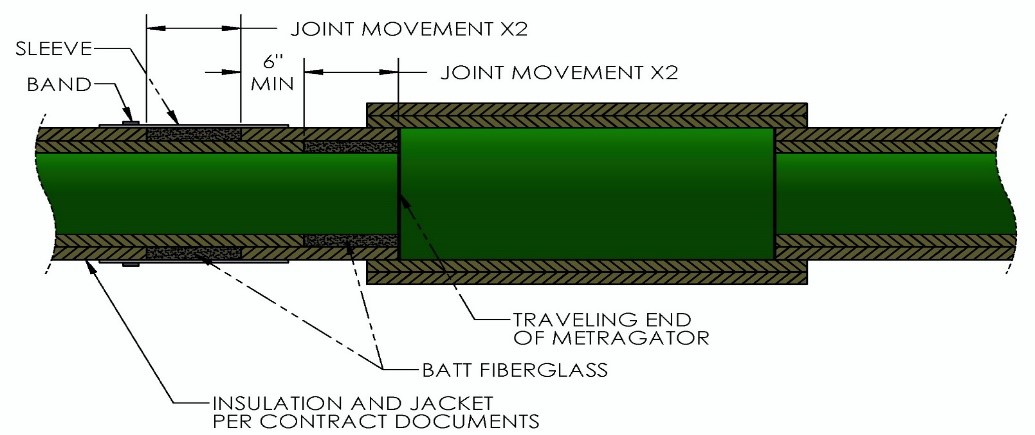

Insulating the Metragator Externally Pressurized Expansion Joint

The higher temperatures associated with steam require substantial insulation. Since expansion joints move in the piping system, insulating them might seem tricky. Once again, Metraflex makes your job of specifying easy by providing instructions for proper insulation.

Metraflex has three options for insulating steam expansion joints. Call your R L Deppmann sales engineer to discuss the three options so we can help you make a better decision in your specification documents.