The cold fill pressure setting in a closed hydronic heating or cooling system is still one of the key problems uncovered when our customer service department is called about comfort complaints. Once the proper pressure is identified and set correctly, should you keep the makeup line open or closed? There are two sides to the story.

What are the “Pros” to Keeping the Cold-Water Makeup Valve Closed?

- The number one reason to do this procedure is that Bell & Gossett recommends it. The final step of setting the pressure reducing valve (PRV) in the IOM number V55999N is closing the cold water shutoff valve. Why do they recommend this?

- If the cold-water makeup valve is left open, a small leak could go unnoticed and the continuous freshwater makeup could damage some of the components in this supposedly closed system.

Many physical plant managers and operators have a real concern about the hidden makeup. Later in this article, we will offer some suggestions.

What are the “Pros” to Keeping the Cold-Water Makeup Valve Open?

- With a small leak, the top of the system will remain pressurized and there will be fewer comfort complaints.

- If the pumps and heating/cooling sources are on the upper floors, there will be less chance of seal leakage, low flow/level shutdown, or equipment damage.

- There will be less labor spent chasing air in the system and complaints from people in the building.

So how do we enjoy the advantages of keeping the valve open and the advantages of keeping the valve closed?

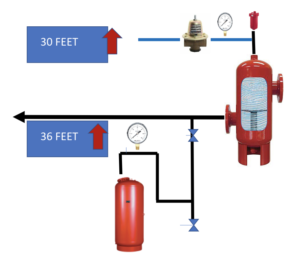

How Does the Water Makeup System Work?

If we keep the water makeup on, we will always have the cold fill pressure available to the system. If the system pressure drops below the PRV set pressure, the makeup PRV will allow the leaked water to be replaced with fresh city water.

The pressure at the expansion tank will rise in a heating system as the water temperature increases. The amount of this pressure rise is a function of the expansion tank size. When the system temperature drops due to spring and fall cycling or night setback, this pressure will drop down towards the cold fill pressure. If there are leaks in the system, this is when the makeup will occur.

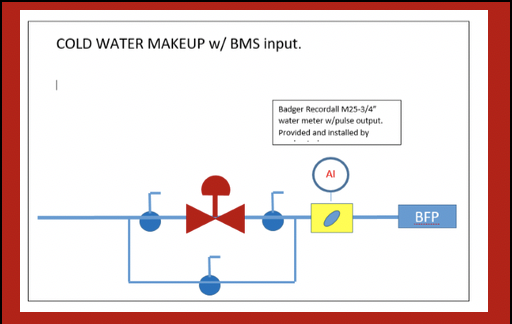

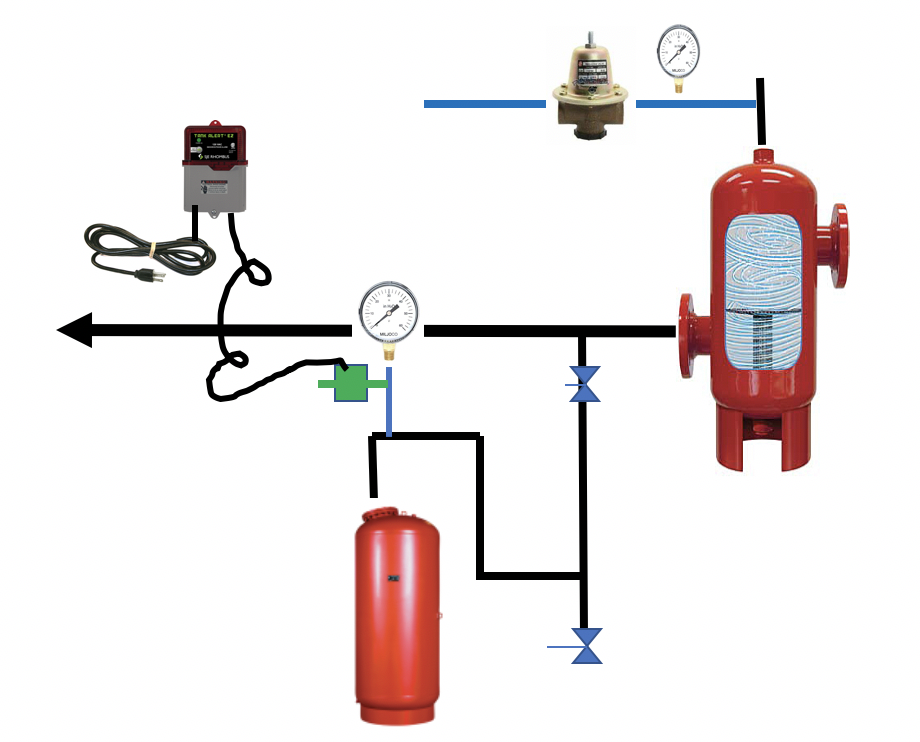

If we want the benefit of opening the system makeup but still want to know if there is an issue before the damage starts, R. L. Deppmann has a solution.

If we want the benefit of closing the system makeup but still want to know if there is an issue before the complaints start, R. L. Deppmann has a solution.

A 110V low-pressure alarm system with a range of 0-10 PSIG or 4-45 PSIG with pressure switch and power cord. This alarm will alert facility operators or maintenance to system operating pressures below-set point. Once you receive an alarm, you can then open the make up and restore pressure for safe operation.

How Does the Glycol Makeup System Work?

| Bell & Gossett GMU glycol makeup unit | Wessels GMP glycol makeup system |

The system responds exactly as the water system above. We recommend you always use a glycol makeup system. If we use city water makeup, the glycol will become diluted over time. The makeup system model GMU from B&G or the GMP from Wessels have low level alarms so your operators/maintenance staff or building management System (BMS) can see the low-level condition and know makeup has occurred.

The makeup system can be filled with premixed glycol which is available from Deppmann.

Whether you want to keep the makeup open or closed, R. L. Deppmann has a solution for you.