I recently visited a school mechanical room and was asked about the relationship between the makeup pressure reducing valve setting and the expansion tank pressure setting. I was also asked about how often to check the pressures in the system.

I recently visited a school mechanical room and was asked about the relationship between the makeup pressure reducing valve setting and the expansion tank pressure setting. I was also asked about how often to check the pressures in the system.

Hydronic Cold Fill Pressure and Expansion Tank Air Pressure – What’s the Rule of Thumb?

The facilities director of a school district asked about some routine numbers and procedures to make sure the starting pressures in the system were correct. He had used a tank air charge number of 2 PSIG more in the tank than at the makeup pressure reducing valve (PRV) as a rule of thumb. At first, I questioned the number but as I thought about it more, it made sense.

Cold fill pressure is defined as the pressure required to fill to the top of the system plus 4 PSIG. Things are best set when system temperatures are below 90°F. As the heating system temperature increases, so does the system pressure. At the PRV, the fill pressure is determined by:

- Identifying the elevation of the hydronic system above the PRV

- Convert that number from feet to PSI and round up. (Dividing that by 2.31)

- Add 4 PSIG in systems with operating temperatures under 210°F (most systems)

This will give you the setting at the PRV. The tank air side pressure setting will be calculated the same way but using the elevation from the top of the tank.

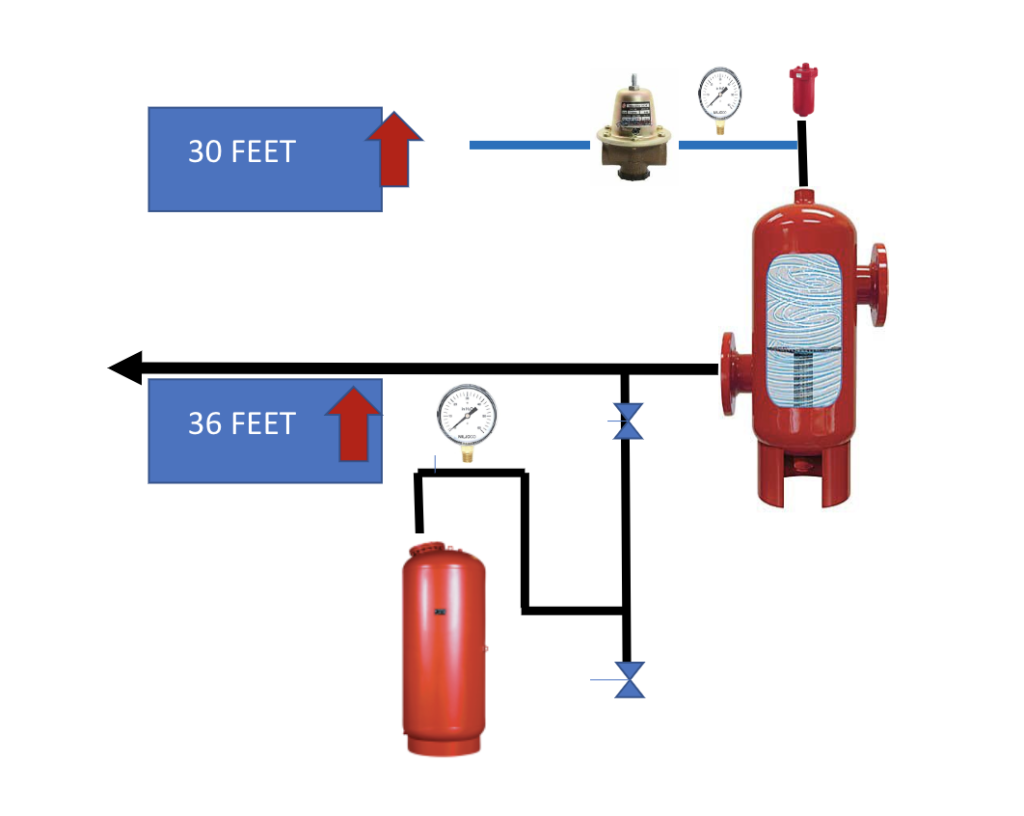

Let’s look at an example assuming the top of the heating system piping is 30 feet above the PRV.

- Identifying the elevation of the hydronic system above the PRV

- Answer: 30 feet

- Convert to PSIG

- Answer: 30 ÷2.31 = 12.98 or 13 PSIG

- Add 4 PSIG

- Answer: 13 + 4 = 17 PSIG cold fill pressure

The tank pressure uses the same formula. The system is 36 feet above the top of the tank. So, the tank pressure is (36 ÷ 2.31) + 4 = 20 PSIG. Since the floor mounted tank is usually about 5 or 6 feet below the PRV, it is reasonable to set the tank about 2 PSIG higher than the PRV. It is close enough if the formula does not come to mind quickly.

Is There Maintenance on Expansion Tanks?

A hydronic system should be completely closed. There should be no leaks and the cold fill pressure should remain constant at room temperature. The PRV should not need to be adjusted. If the system pressure dropped because some water was removed from the system, a chemical test for example, the PRV will automatically make up the water and maintain the pressure.

When we look at the bladder tank, there is some maintenance required. The bladder in these tanks is air permeable. Over a long time, the air will move from the tank through the bladder and into the system. This will reduce the air charge. This could be years and the time is based on the tank size and cycling. Bigger tanks have more bladder square feet and cycling expands and contracts the bladder more often.