Engineers schedule a pump capacity in GPM and head along with the horsepower. The pump manufacturer traditionally trims the impeller from the maximum size, also called a “full runner,” to the size that meets the requested flow and head. There is another option when the pump is operated with a variable speed drive (VFD). Someone can trim the speed down to the design capacity from a larger impeller. Which solution should you expect?

Pump Impeller and Speed, How Are They Related?

I know, I know! Can Norm ever write a blog without some formula? Probably not, but I will keep it simple. The first pump affinity law states that flow is proportional to speed or Hertz and proportional to impeller diameter.

For today, all we want to discuss is the portion above in red. This says that if I change the speed of a pump from 1750 RPM to 1575 RPM, 10%, the flow and head in a closed hydronic system will be the same as if I trimmed the impeller 10%. If I trim the impeller 10% from 12” to 10.8”, it is the same as changing the speed from 1750 to 1575 RPM.

The end result is a pump with a VFD could be supplied with a larger impeller and be artificially trimmed in the field by reducing the speed. The ASHRAE 90.1 energy standard uses this fact to save energy used by an over-headed pump design.

Why Should I Not Trim the Impeller?

Why should I save the pump manufacturer the cost of trimming an impeller? The pump sell price does not change, so why would I want a larger impeller. There are two possible advantages to having a larger impeller and trimming the maximum speed of the motor using the VFD.

The first has everything to do with the pump Best Efficiency Point or BEP. The BEP is a tested flow and head point of a full runner impeller which offers the best efficiency. The full runner impeller will always be the impeller with the best efficiency point. As we trim an impeller, the velocities and turbulence at the outlet of the impeller change and we lose some efficiency. Let’s look at a curve.

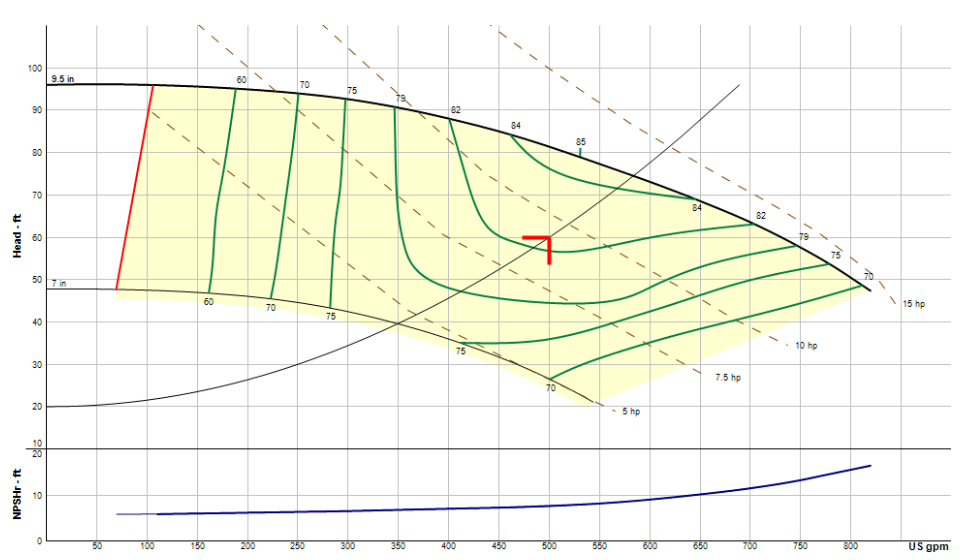

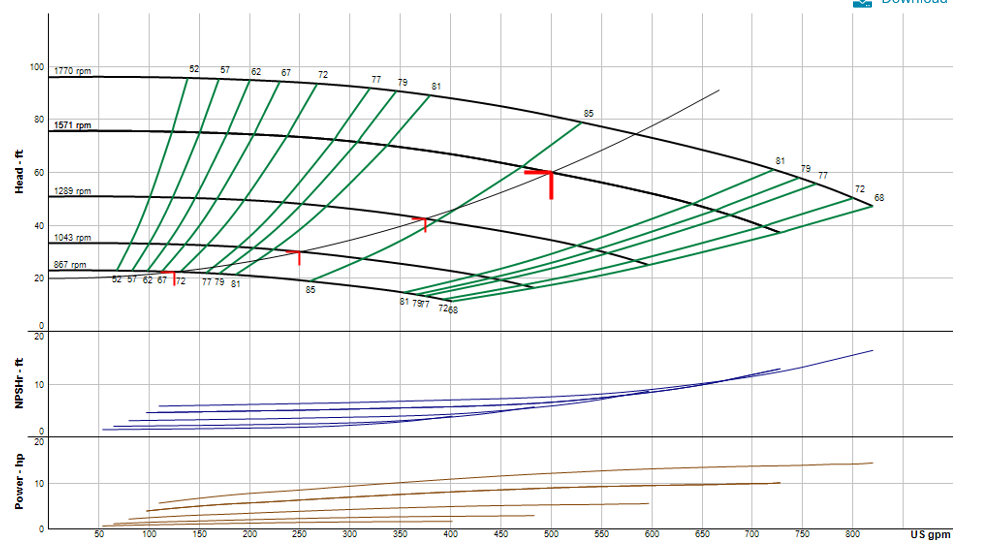

Here is a constant speed curve for a e-1510-3BD from the Bell & Gossett ESP-Systemwize selection program. Notice at the full runner 9.5” impeller there is a point, the best efficiency point, at roughly 530 GPM at 80 feet where the efficiency is 85%. The efficiency of the impeller trimmed to design at 8-5/8” is about 82.4%.

The non-overloading HP with the trimmed impeller is 10.1 so we might put a 15 HP motor on this pump. The 10 HP could actually be used in this selection since it will not overload until it gets to 700 GPM or 40% over design. It would be difficult to miss the design or balance by that much.

If I trim the impeller, what does the variable speed curve look like?

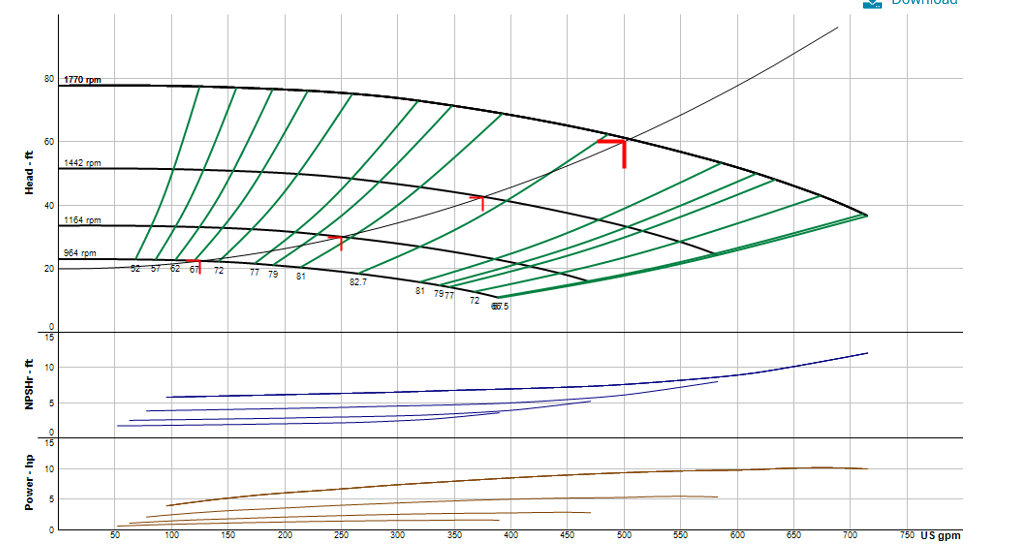

You can see the trimmed impeller efficiency at design is 82.4% as mentioned above. Now let’s look at the variable speed curve for the same pump at the same capacity but with a 9.5” full runner impeller. You will need to look closely since the two curves look similar, but the speed and impeller changed.

If we use the 9.5” full-sized impeller and adjust the speed down to 1571 RPM, the pump will give the design flow and head, but the efficiency is now 84.4%. This is an increase of 2.0% over the trimmed impeller. The pump is non-overloading with the 15 HP motor at both full speed and the 1571 design speed. Seems like this is a win-win in this example.

The second reason is all about safety factor. We tend to like a great deal of safety factor into pump head calculations. Having a larger impeller than needed for the capacities gives you even more upside head capacity. Remember that you cannot have more capacity than you have horsepower. In the example above we said a 10 HP motor would work. If the pump is supplied with 10 HP, there is no upward potential. If supplied with 15 HP, there is plenty of upside capacity.

Next week we will look at the reasons and times you may not want to use a full runner impeller and trim with the drive speed.

1ANSI/ASHRAE/IES Standard 90.1-2013 Energy Standard for Buildings Except for Low-Rise Residential Buildings