The prevention of Legionella growth in plumbing systems is a topic on most of our minds. As a result, plumbing industry standards are paying a lot more attention to temperature management in domestic hot water systems, also known as service water systems. The next few R. L. Deppmann Monday Morning Minutes will address the flow balance in domestic water recirculation systems and its part in temperature control.

Calculating Flow and Head in Domestic Hot Water Recirculation Systems

The purpose of the recirculation system is to provide hot water quickly at the fixtures in times of heavy hot water use and also in times of little or no use. This saves water and also time.

The calculation of the required flow rate in the standard recirculation system is well documented. Our Monday Morning Minutes article, Designing Domestic Hot Water Recirculation Systems: Part 1 Determining the Flow Rate, offers a quick summary of the calculation for flow rate.

The pump head calculation is normally determined by treating the system as a closed system in times of little or no water usage. We outlined this in our Monday Morning Minutes article, Designing Domestic Hot Water Recirculation Systems: Part 2 Determining the Pumping Pressure Drop.

These articles did not review the types of balance valves used, so we will address it now.

“Good” Flow Balance Using Manual Valves

If we use the Good, Better, and Best descriptions of domestic water recirculation balancing, here is how I would break it down.

If we use the Good, Better, and Best descriptions of domestic water recirculation balancing, here is how I would break it down.

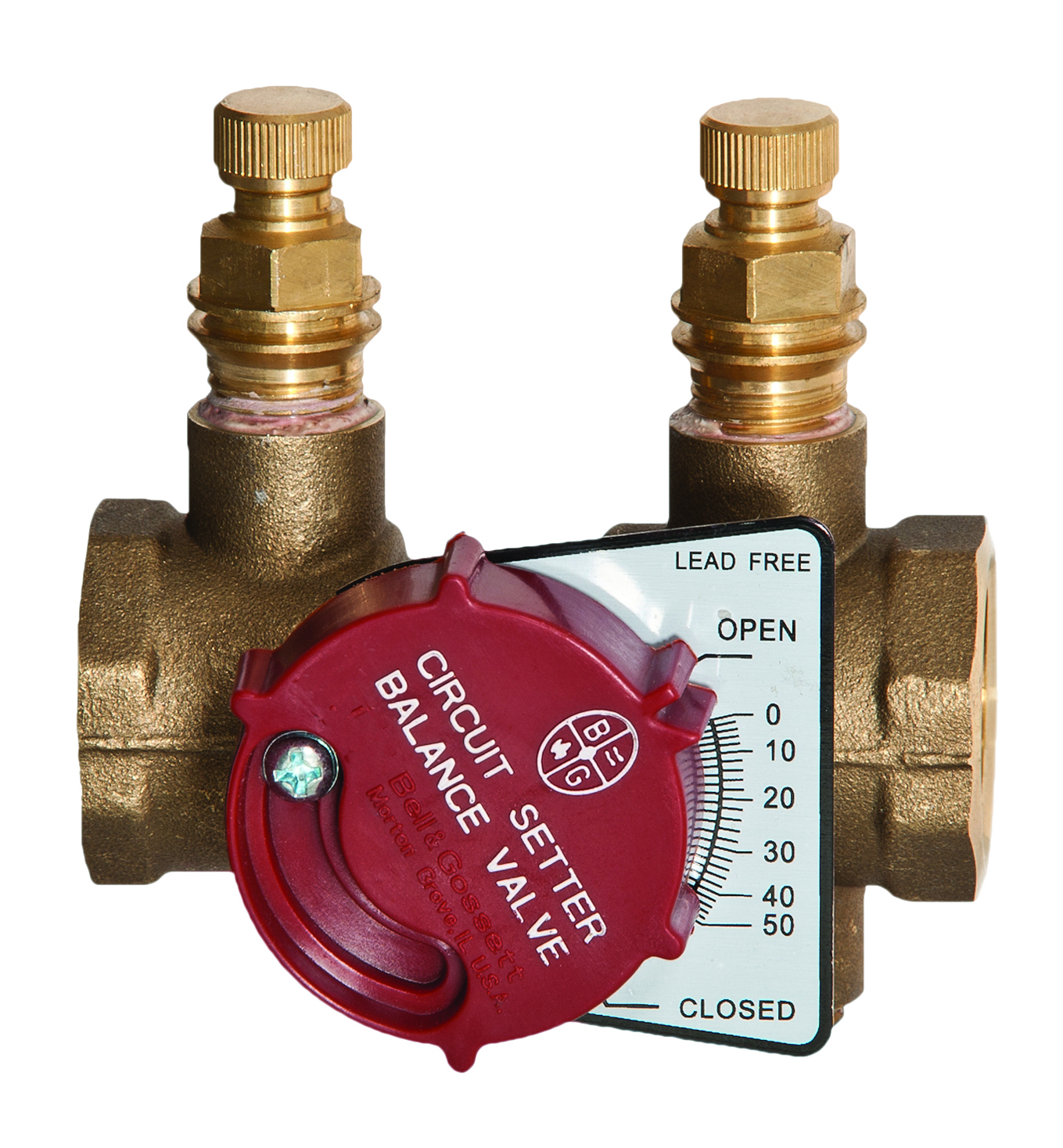

The traditional larger system uses balancing valves at or near the end of main. The balancing valves used most often are manual calibrated combination flow and balancing devices such as the Bell & Gossett low lead circuit setter.

This balance valve allows the plumbing contractor to have the system balanced by throttling the valve. The ports provided allows reading out the pressure drop and referring to programs or tools to determine the flow rate during and after adjusting the valve. A memory stop assures the valve will be returned to the correct setting if the valve is used for its 100% shutoff capability during service.

The Good method of balance is tried and true. It assumes the balance valves are installed and that they are properly set. This method also assumes that no one changes the setting later in the life of the system. This Good method will result in a constant flow system which could waste energy if zones are satisfied due to usage in the building.

“Better” Flow Balance Using Automatic Flow Limiting Valves

In my opinion, the Better recirculation flow balance solution would use automatic flow limiting valves, valves similar to the Griswold lead-free “K” valve.

In my opinion, the Better recirculation flow balance solution would use automatic flow limiting valves, valves similar to the Griswold lead-free “K” valve.

These valves are factory set to a given GPM within a pressure range. The flow rate would be the flow rate calculated by the engineer. The pressure drop range is also easy to determine. The pump head is the maximum differential, so choose the range with the lowest starting pressure drop that contains the pump head. This will usually be the lowest range available.

These valves will self-adjust to maintain the flow rate. They do not require the plumbing contractor to set the valve, and the owner cannot open them later in the life of the system. For these reasons, I deem this to be a Better solution. This type of balance is also constant flow, so energy will be wasted.

“Best” Flow Balance Using Temperature.

The new kid on the block is a thermostatic balance valve. This Best solution will be the subject of next week’s R. L. Deppmann Monday Morning Minutes.