Dual return condensing boilers can enhance the efficiency of your heating plant by 3-6%. How can an HVAC and Plumbing engineers design the system to take advantage of this technology? The R. L. Deppmann Monday Morning Minutes has 6 quick examples.

Dual return condensing boilers can enhance the efficiency of your heating plant by 3-6%. How can an HVAC and Plumbing engineers design the system to take advantage of this technology? The R. L. Deppmann Monday Morning Minutes has 6 quick examples.

The Advantage of Dual Return Condensing Boiler Technology

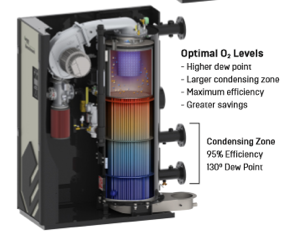

I outlined the advantages of this technology in a previous article, Condensing Boilers – Use Dual Returns for Greater Energy Savings. The key to this technology is to design a system with two separate return pipes rather than combining them into a single return. By doing this, the boilers will condense more often and at a higher efficiency.

The lower the return temperature, the higher the efficiency. Even a relatively small percentage of low-temperature returns will have a nice ROI for the owner of the boilers. Let’s look at 6 easy application examples.

#1: Radiant Heating

Radiant heating systems would use a primary-secondary bridge to reduce the temperature to the radiant zone. A typical temperature range for these systems would be 120°F supply and 100°F return.

#2: Snow Melt

Snow melt systems normally employ a small heat exchanger and a propylene glycol loop for the snow melt. The heat exchanger should be sized for lower boiler water temperature than design when using outdoor air reset on the boiler supply. A typical temperature range for the glycol side would be 110°F supply and 100°F to 90°F return.

#3: Domestic Hot Water

Using a heat exchanger and control package as the domestic water heater when using dual temperature return boilers is a very efficient way to maximize the return on a condensing boiler investment. The municipal water supply temperature in Michigan and Ohio is around 40°F to 50°F. Even a comfortable 10°F approach will result in boiler return temperatures of 60°F.

#4: Indoor Pool Water Heating:

Again, a heat exchanger is employed in this application. An earlier R. L. Deppmann Monday Morning Minutes series on pool heaters has much more information. It can be a plate type or shell and tube. The return water temperature could be 80°F to 100°F.

#5: AHU Units – 3-4 Row

This is an application we don’t think of too often. The real money in Air handling Units (AHU) is in the airside. Changing to more rows in the coil, we can reduce the waterside temperatures from 150°F to 110°F. The systems often have a small secondary pump for freeze protection so using common pipe mixing is a simple adaptation of balance and set points.

#6: Heat Pumps

When designing a heat pump system with a boiler for supplemental heat, remember that condensing boilers do not need controls to raise the return temperature.

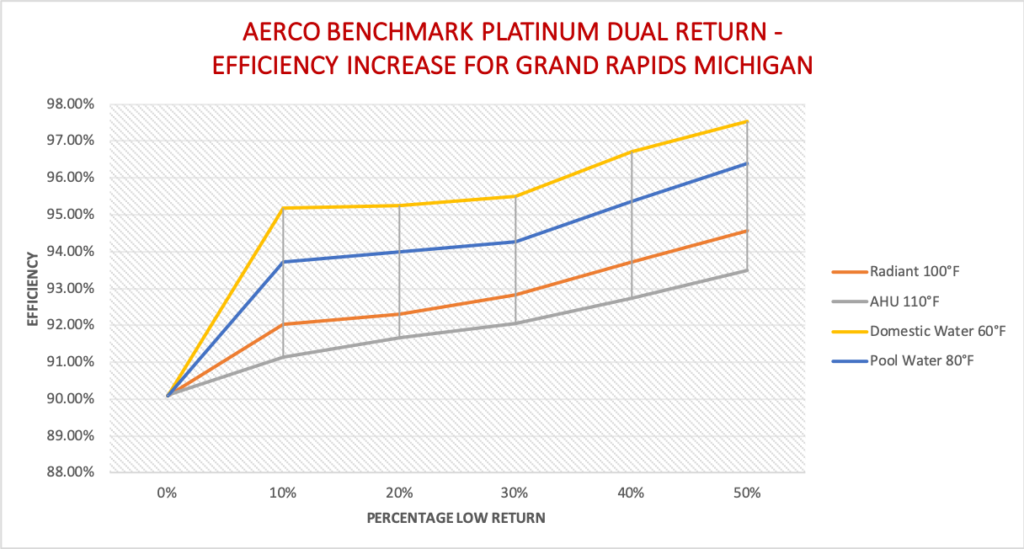

Increased Efficiency vs. Percent of Low-Temperature Return

How much-increased efficiency can I achieve if I use an Aerco Benchmark Platinum boiler with dual returns? How much of a low-temperature load do I need? I used The Aerco boiler efficiency program to create the chart below. I assumed a design of 180°F supply and 140°F return. I also assumed an outdoor reset system with a 40°F drop in supply. Finally, I used a total load of 1.8 MBH and an Aerco BMK-2000 Platinum boiler. The starting point of 0% assumes no lower temperature design is incorporated.

The result of using the Aerco Benchmark Platinum with dual returns can result in annual savings for this Grand Rapids Owner of roughly $2,000.00 per year or more! The additional piping will cost more but the return on investment (ROI) would be less than 3 years. After that, your client will enjoy the savings year after year.

What can we do in the design stage to get lower temperature returns? We’ll look at more detail in the upcoming R. L. Deppmann Monday Morning Minutes. Meanwhile, use the examples above or create your own. Give us a call or click “learn more” below and our engineers can discuss your project details and run a specific report of energy savings for your application and installation location.