Several people have asked about the three system connections on the photos of Aerco Platinum condensing boilers shown in the R. L. Deppmann Monday Morning Minutes from last week. What if I told you these connections allow you to save an additional 3-6% of energy cost through fuel efficiency savings? Let’s look at how you can provide this winning strategy for your client.

Several people have asked about the three system connections on the photos of Aerco Platinum condensing boilers shown in the R. L. Deppmann Monday Morning Minutes from last week. What if I told you these connections allow you to save an additional 3-6% of energy cost through fuel efficiency savings? Let’s look at how you can provide this winning strategy for your client.

Condensing Technology is all about Return Temperature

When using condensing boilers, the ultimate goal of the engineer should be to design a system that causes the boiler to condense most of the time. This may require different types of terminal units as well as different average design temperatures in those units. Let’s look at an example.

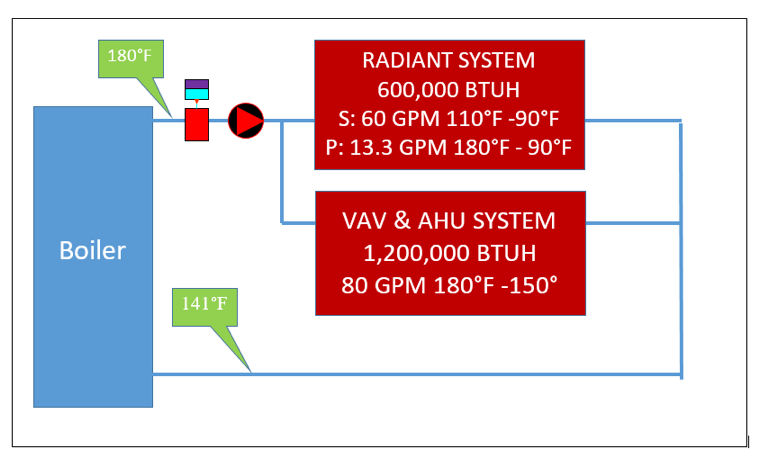

The system above has 2/3 of the load with a design return temperature of 150°F and 1/3 of the load with a design return temperature of 90°F. We need a maximum of 135°F (prox) return temperature to start condensing. We know that the 150°F return temperature will not cause condensing. When I mix the returns from the two systems, the design return temperature will be about 141°F. The return temperature will drop as I reset the supply temperature based on the outdoor temperature. The return temperature will be less than 135°F most of the time. This is a good candidate for condensing boilers.

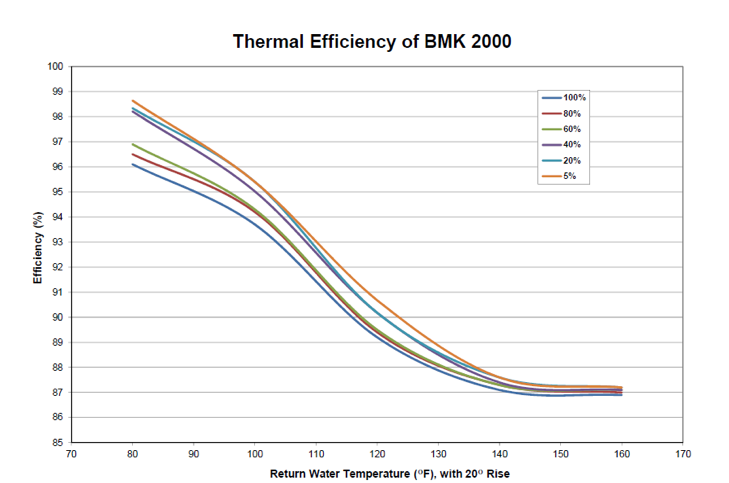

When the return temperature is 141°F, when it is coldest outside, the boiler will operate at 87% efficiency. The efficiency will rise in the spring and fall. In this example let’s assume the boiler is installed in Grand Rapids, Michigan. How much could we save if the boiler had dual returns?

Dual Return Condensing Boilers Increase Efficiency Even More.

Look at the efficiency chart above. If we split the system into two boilers, what would the boiler efficiency look like? The 1,200,000 BTUH load is 2/3 of the total and the 150°F return temperature would result in a design efficiency of 87%.

The 600,000 BTUH load is 1/3 of the total and the 90°F return temperature would result in a design efficiency of 95%. The total of the two boilers will result in an increase in efficiency at the design of 2.9%

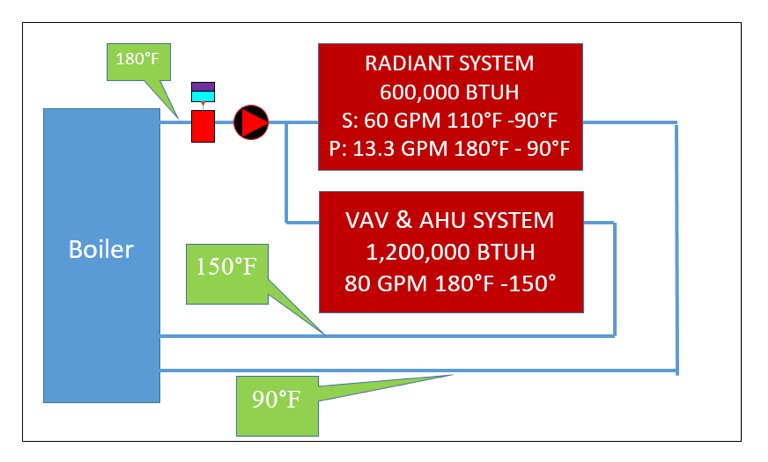

This is exactly what the Aerco Benchmark Platinum does for you. We load the low-temperature returns into the bottom connection and the higher temperature into the upper return.

The result of using the Aerco Benchmark Platinum with dual returns with this example is an increase in efficiency that will save this Grand Rapids Owner roughly $8,000.00 per year! The additional piping will cost more but the return on investment (ROI) will be less than 3 years. After that, your client will enjoy the savings year after year.

What can we do in the design stage to get lower temperature returns? We have some great strategies to share. Check us out next week in the R. L. Deppmann Monday Morning Minutes.