Primary variable pumping systems are common in large commercial hydronic systems using firetube boilers. When we are designing smaller systems with loads less than one million BTUH, both the water tube and firetube boiler manufacturers may recommend primary secondary pumping. Today, the R. L. Deppmann Monday Morning Minutes explores this recommendation and takes the opportunity to introduce a great, new boiler product solution for you.

Boilers and the Quest for Space-Saving

There is a constant battle in new construction projects. The engineers want boilers with great efficiency and high burner turndown to save energy and operating costs. The architects want reduced mechanical room space.

The traditional, older, non-condensing process firetube boilers have large water volumes. Today’s condensing firetube boiler manufacturers are designing the boilers to be smaller with less water content. They combine the condensing efficiency, the turndown capability of the fire-tube, and require less mechanical space.

The penalty for having all these combined advantages appears in minimum flow rate.

Minimum Flow Rate of Condensing Boilers

Water tube condensing boilers have a minimum flow rate and minimum turndown. The minimum flow rate is higher due to concerns about velocity and heat transfer as well as the potential of flashing in the tubes. Visit Water Tube vs. Fire Tube Condensing Boilers: When To Use Them for more about water and fire tube differences.

As the water content drops in the fire tube boiler, the velocity and ability to move the heat out of the boiler also become an issue. The boiler manufacturer may suggest a variable or constant primary-variable secondary piping system rather than a primary variable piping system. To illustrate this, I will introduce a great product to use as an example.

NTI Boilers Introduces the TFTN Fire-Tube Boilers

R. L. Deppmann Company represents and sells a variety of water-tube and fire-tube boilers for the hydronic and process industries. Many of the projects we are asked to participate in involve systems with boilers over a million BTUH. What can we offer when the request is for a fire-tube boiler in the smaller, less than a million BTUH system?

The NTI Boilers TFTN fire-tubes are available starting at 85,000 to 399,000 BTUH as wall-mounted boilers. Then, they manufacture fire-tubes from 500,000 to 850,000 BTUH as floor-mounted boilers.

The benefits of these boilers are many. A few key benefits are:

The benefits of these boilers are many. A few key benefits are:

- Fire-tube condensing thermal and combustion efficiencies up to 97.7%

- 10:1 turndown on most sizes

- Ability to fit through a small standard door with 28” widths or less

- CSD-1 ready and appropriate trim available on larger models

- User-friendly contractor startup with “EZ Setup Wizard”

- Remote access and troubleshooting in real-time

Visit the NTI website for more information.

NTI Boiler Series TFTN Minimum Flow Rate

These boilers, in most cases, have a 10:1 turndown on the burner. As discussed in Turndown Ratio in Condensing Water Tube vs. Fire Tube Boilers that does not mean there is a 10:1 turndown on the flow rate. Here is an example table showing the minimum flow rate on this compact fire-tube boiler series.

| NTI Boiler | BTUH Input | BTUH Output (Prox)* | Example Design Temp | Example GPM** | Minimum GPM*** |

|---|---|---|---|---|---|

| TFTN850 | 850,000 | 722,500 | 150-180 | 48.2 | 25 |

| TFTN725 | 725,000 | 616,250 | 150-180 | 41.1 | 21 |

| TFTN600 | 600,000 | 510,000 | 150-180 | 34.0 | 17 |

| TFTN500 | 500,000 | 425,000 | 150-180 | 28.3 | 14 |

| TFTN399 | 399,000 | 339,150 | 150-180 | 22.6 | 15 |

| TFTN340 | 340,000 | 289,000 | 150-180 | 19.3 | 13 |

| TFTN285 | 285,000 | 242,250 | 150-180 | 16.2 | 11 |

| TFTN199 | 199,000 | 169,150 | 150-180 | 11.3 | 8 |

| TFTN150 | 150,000 | 127,500 | 150-180 | 8.5 | 6 |

| TFTN110 | 110,000 | 93,500 | 150-180 | 6.2 | 4.4 |

| TFTN085 | 85,000 | 72,250 | 150-180 | 4.8 | 3.5 |

* Based on 85% efficiency with non-condensing return temperatures. See literature for exact efficiency at various return temperatures.

** Assumes the fluid is water.

*** From NTI model TFTN IOM dated 08-15-2023.

We can see in the larger models a minimum flow rate of about 50% of the design flow rate at a 30°F ΔT.

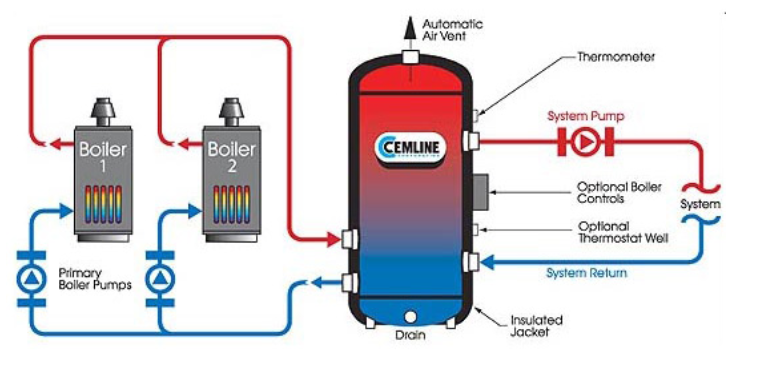

The factory IOM has the following statement, “To ensure the minimum flow rate is attained, NTI strongly recommends installing the boiler in a “Primary/Secondary” plumbing configuration utilizing “Closely Spaced Tees” or a “Low Loss Header” to de-couple the Boiler-Primary loop from the System-Secondary loop(s).”

Next week in part 2, we will look at an example of why the above statement is shown and when the engineer might choose to follow or not follow the recommendation.