The commercial condensing boiler market is flooded with choices. Once choice is obviously the manufacturer. But before you even get there the question could be, and maybe even should be, whether to use a water tube or fire tube boiler? What is the difference between these two boilers?

Water Tube and Fire Tube Boilers – What is the Difference?

Representation of Bryan Water Flex Tube Boiler

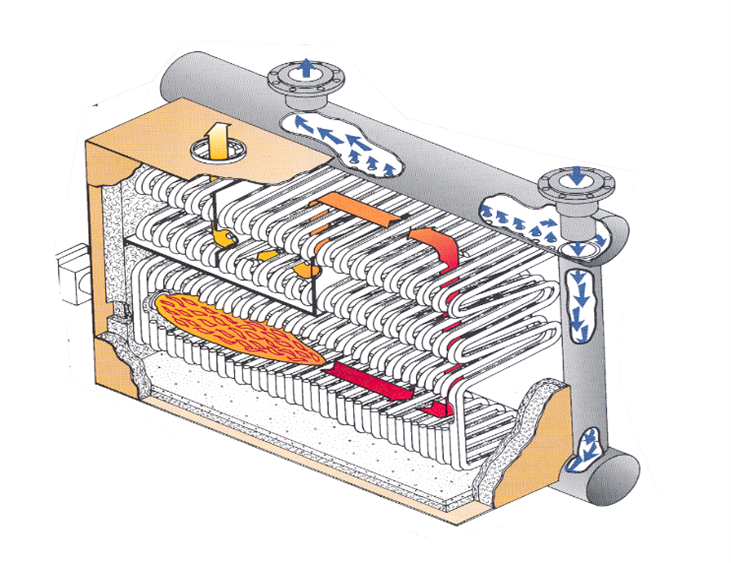

Representation of Aerco Fire Tube Boiler

It may be obvious from the names, but what is a water tube boiler? As the name implies, the water is inside the tubes. Water flows through the tubes of the boiler and the fire and hot gases are on the outside of the tubes. This is like a shell and tube heat exchanger where the water flows through the tubes and steam flows on the outside of the tubes. The water side heat transfer coefficient is high in tubes with turbulent velocity.

In a fire tube boiler, the flame starts, and the hot gases move inside of tubes while the water surrounds the tubes. The water is flowing outside the tubes. The heat transfer coefficient is lower with water flowing on the outside of the tubes, so there is more surface required. There are several consequences to each design.

Water Tube Boiler Operation

Temperature Differential: These boilers have less water content. That makes them very responsive to changes in temperature. The water tube styles usually have a limited temperature differential. Many of these boilers have the tight temperature range of between 20° ΔT and 40° ΔT. A small volume of water is flowing in the tubes. The tube is surrounded by hot gas. Tighter temperature differentials help keep expansion and temperature spikes to a minimum protecting the heat exchanger from damage.

Velocity: Water in the tubes will also influence the required velocity. The hot gas is around the tubes. The temperature of the gas does not vary. As the flow in the tube drops, the water is in the tube longer and the temperature of the water rises. But, as mentioned above, we want to limit the temperature rise. Minimum velocity becomes very important. Velocity is limited to avoid temperature spikes and to keep the flow rate turbulent. There is also a limit to the velocity which defines the maximum flow rate.

Pressure Drop: The tube velocity and length are higher to achieve the rated heat transfer. This will also result in a higher pressure drop in the tubes.

Piping System: In a variable flow system with two-way control valves, primary- secondary piping is normally recommended by the water tube boiler manufacturer. The higher minimum flow rate and limited boiler temperature differential are hard and set rules. The variable flow system the boilers are attached to may act differently than the design depending on load variations, system balance, safety factors, and how the owner uses the system.

To protect the boilers, the manufacturer may require or strongly suggest the use of a decoupled, primary-secondary pumped mechanical room.

First Cost: Seems like a great deal of limitations are mentioned for water tube boilers. What is the advantage? The water tube boiler will, in general, cost less than the fire tube boiler. The water tube boiler may also use less mechanical room space. Both are important in new construction of buildings.

Operating Cost: We will discuss this in a later article on turndown.

Fire Tube Boiler Operation

Just as the name implies, this type of boiler has fire or hot gases in the tubes. The water is outside the tubes. The boiler contains a lot more water. The system expansion tank volume will be larger due to more water content.

Temperature Differential: There is a lot more water in the boiler. This type of boiler will normally accept higher temperature differentials. The 35°F to 40°F ΔT will normally not be a limitation. The engineer is free to raise the design delta T and lower the design flow rate as recommended by the manufacturer.

Velocity: The hot gases are in the tubes. The velocity of the water will be less at design. With the higher water content there is less concern about temperature spikes. There will be a minimum flow rate, but that flow rate is normally much lower than an equivalent water tube. The low flow is only limited by the need to remove the excess heat after the burner shuts down.

Pressure Drop: There is less velocity and more space for water in the fire tube boiler. In general, the pressure drop for a given size will be less.

Piping System: These reasons lead most manufacturers to offer the product for use in either variable primary piping designs with a minimum flow rate requirement or primary secondary piping design. If the literature does not specifically allow primary variable, ask the representative to query the manufacturer. Make sure you receive the manufacturer’s recommendation and not just that of the representative or distributor.

First Cost: These fire tube boilers have more complicated internal controls and burners. The first cost will be higher. The boilers may also be larger due to the larger water content.

Operating Cost: We will discuss this in a later article on turndown.

These reasons lead most manufacturers to offer the product for use in either variable primary piping designs with a minimum flow rate requirement or primary secondary piping design.

Which One Should I Use?

R. L. Deppmann represents several boiler manufacturers. Each model has sizes, boiler types, features, and benefits which your client may value.

Condensing** Boilers by R. L. Deppmann* (Sorted Smallest to Largest)

| BRAND | MODEL | MBH SIZE RANGE | TYPE | PIPING*** |

|---|---|---|---|---|

| NTI | TFTN | 085-850 | Fire tube | PS |

| NTI | LX | 150-800 | Water tube | PS |

| Thermal Solutions | APEX | 425-825 | Water tube | PS |

| Aerco | MODULEX | 450-3000 | Water tube | PS |

| Aerco | AM | 500-1000 | Water tube | PS |

| Aerco | BENCHMARK | 750-6000 | Fire tube | PV |

| Bryan | BFIT | 1000-4000 | Water tube | PS |

| Thermal Solutions | AMP | 1000-4000 | Water tube | PS |

| Bryan | FF | 1000-6000 | Water tube | PV |

| Thermal Solutions | ARTIC | 1000-6000 | Water tube | PV |

| NTI | FTG | 600-2400 | Fire tube | PS |

| Aerco | MFC | 3000-10,000 | Fire Tube | PV |

| * Some boilers are not available in all territories |

| ** List is limited to Condensing hydronic boilers, does not include steam or non-condensing models such as Burnham. |

| *** PS = Primary Secondary Suggested, PV – Primary variable or Primary Secondary |

Next week we will explore boiler turndown and the effect on operating costs as well as the design.