Proper venting of hydronic condensing boilers is critical for the safety of occupants and the successful operation of the heating plant. The materials that may be used for venting the flue gases are defined by codes and the manufacturers of the appliances. Once the engineer and contractor know the choices of materials allowed, which material should they recommend?

Proper venting of hydronic condensing boilers is critical for the safety of occupants and the successful operation of the heating plant. The materials that may be used for venting the flue gases are defined by codes and the manufacturers of the appliances. Once the engineer and contractor know the choices of materials allowed, which material should they recommend?

In this article, we will review the pros and cons of many materials available for venting, including some key points from various codes in Michigan and Ohio. This is not an in-depth study of codes. It is important for the reader to verify all state and local codes, as well as the requirements of the boiler manufacturer.

Condensing Boiler Materials Available

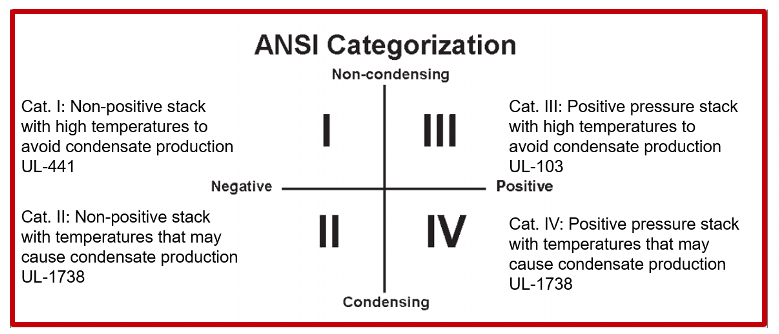

The search for the vent materials available to use in hydronic boilers should start by identifying the American National Standards Institute (ANSI) appliance category. ANSI uses the term appliance. By using the term appliance, they avoid describing all types of gas fired equipment that would need venting. This blog is specifically looking at the appliances we call commercial hydronic boilers. What materials are normally discussed?

There are currently four main condensing boiler exhaust venting materials.

- PVC or Polyvinylchloride pipe. Often used in condensing furnace venting. A few hydronic condensing boiler manufacturers allow it to be used for exhaust venting. Different manufacturers publish maximum temperature rating of 140⁰F to 158⁰F with little or no pressure present. It is not listed in the United States (US) for use as vent material for category II and IV appliances.

- cPVC or Chlorinated Polyvinylchloride pipe. Also allowed by some condensing boiler manufacturers. It has a published maximum temperature rating of 180⁰F with little or no pressure present. It is not listed in the US for use as vent material for category II and IV appliances.

- PP or Polypropylene pipe. Commonly shown as an acceptable vent material by hydronic condensing boiler manufacturers. It has a published maximum temperature rating of 180⁰F with little or no pressure present. It is listed in the US for use with category II and IV appliances.

- AL29-4C or Super-ferritic stainless-steel special purpose pipe. This is accepted by all hydronic condensing boiler manufacturers I am aware of at this time. It has a published maximum operating temperature rating of 480⁰F with little or no pressure present. It is listed in the US for use with category II and IV appliances.

Condensing Boiler Categories and Listing

The appliances are defined into categories. Condensing boilers may fall under category II or IV appliances. The manufacturer will identify which category to use.

Most codes will reference the International Fuel Gas Code for venting requirements. What does it say about the use of materials? Section 502 is all about these vents. Section 502.1 of this document provides a bit of confusion. It is worth looking at the exact words.

“Vents, except as provided in Section 503.7,

shall be listed and labeled. ….. Plastic vents for Category IV

appliances shall not be required to be listed and labeled

where such vents are as specified by the appliance

manufacturer and are installed in accordance with the

appliance manufacturer’s instructions”.

So, our vent piping must be listed and labeled, unless it is the lower priced plastic. The appliance (or equipment) manufacturer is responsible to determine whether to use the plastic pipe or not and how to install it.

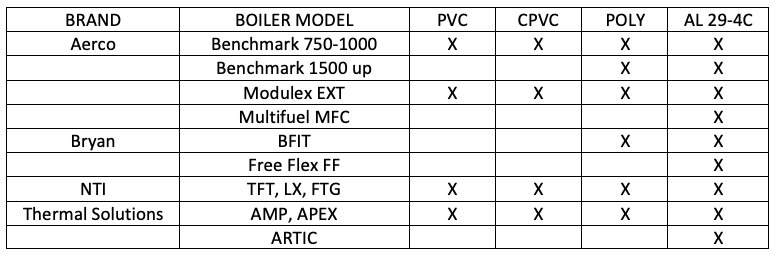

What Do Hydronic Boiler Manufacturers Allow?

What do the manufacturers say about the materials to use? We are aware that some manufacturers allow all four materials to be used. Many do not. As a manufacturer’s representative we will speak to the brands we represent. As of the posting of this blog, here is what materials the following manufacturers publish may be used.

All the manufacturers have various rules, listings, brands of vent, and installation instructions that must be followed. Just because the material is allowed does not mean they recommend it. Read the venting IOM before deciding what to use as well as installing.

Why would one vent material be better than another? How does first cost and installation costs line up? What would R. L. Deppmann recommend? We will explore the answers to these questions in Part Two, which will go live next Monday.