Turndown was defined in Part 1 of this short series. In general, hydronic water tube boilers have a lower possible turndown ratio than fire tube style boilers. Why is the turndown different? What other limitations are there based on the type of boiler?

Turndown was defined in Part 1 of this short series. In general, hydronic water tube boilers have a lower possible turndown ratio than fire tube style boilers. Why is the turndown different? What other limitations are there based on the type of boiler?

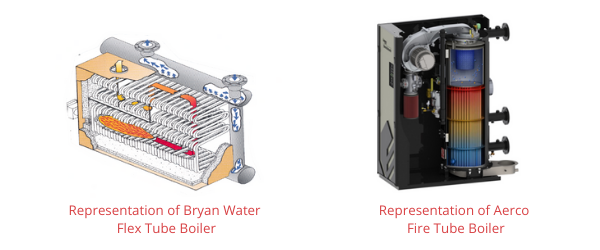

Water Tube and Fire Tube Boilers – What is the Difference?

In a fire tube boiler, the flame starts, and the hot gases move inside of tubes while the water surrounds the tubes. The water is flowing outside the tubes. The coefficient is lower with water flowing on the outside of the tubes, so there is more surface required.

There are several consequences to each design. It may be obvious from the names but what is a water tube boiler. As the name implies, the water is inside the tubes. Water flows through the tubes of the boiler and the fire and hot gases are on the outside of the tubes. This is like a shell and tube heat exchanger where the water flows through the tubes and steam flows on the outside of the tubes. The water side heat transfer coefficient is high in tubes with turbulent velocity.

Water Tube Boilers and Turndown Limits

These boilers have less water content. That makes them very responsive to changes in temperature. The water tube styles have a limited temperature differential. Most of these boilers have a tight temperature range between 20° ΔT and 40° ΔT. Since the water is in the tubes, they require a minimum velocity to keep the flow turbulent. There is also a limit to the velocity which defines the maximum flow rate. Widely varying flows, outside these limits, will cause possible flashing or tube damage.

Part 1 of this series described these boiler turndowns in the range of 5:1.

To be fair, there are water tube boilers with larger turndown ratios but, these will normally have multiple heat exchangers in parallel inside the boiler. The heat exchangers are staged for a higher turndown while maintaining the proper flow rates. Depending on State codes, these boilers may have multiple CSD-1 requirements.

In a variable flow system with two-way control valves, primary secondary piping is normally recommended by the manufacturer.

Fire Tube Boilers and Turndown Limits

Fire tube design hydronic boilers do not have the velocity limitations imposed by water in the tube designs. The flow rate can be as high as the maximum caused by mechanical and pressure drop limits. The low flow is only limited by the need to remove the excess heat after the burner shuts down.

There is much more water content in this type of boiler and each drop of water is in the boiler longer. These boilers may employ much higher differential temperature ranges than a similar water tube design.

These reasons lead most fire tube manufacturers to recommend either variable primary piping designs with a minimum flow rate requirement or primary secondary piping design.

Which One Should I Use?

R.L. Deppmann represents several boiler manufacturers. Each model has sizes, boiler types, features, and benefits which your client may value.

| Condensing** Boilers by R.L. Deppman* (sorted smallest to largest) |

||||

|---|---|---|---|---|

| BRAND | MODEL | MBH SIZE RANGE | TYPE | PIPING*** |

| Cemline | EHB | 040-7000 | Electric**** | PV |

| Thermal Solutions | APEX | 425-825 | Water tube | PS |

| AERCO | AM | 500-1000 | Water tube | PS |

| AERCO | BENCHMARK | 750-6000 | Fire tube | PV |

| Bryan | BFIT | 400-4000 | Water tube | PS |

| Thermal Solutions | AMP | 400-4000 | Water tube | PS |

| Bryan | FF | 1000-6000 | Water tube | PV |

| Thermal Solutions | ARTIC | 1000-6000 | Water tube | PV |

| * Some boilers are not available in all territories | ||||

| ** List is limited to Condensing hydronic boilers, does not include steam or non-condensing models such as Burnham. | ||||

| *** PS = Primary Secondary Suggested, PV = Primary Variable or Primary Secondary | ||||

| **** Electric boilers obviously do not condense. | ||||

The choice of one boiler over the other boils down (pun intended) to five things:

- Consider cost. Normally, for the same output, the water tube condensing design will cost less to purchase.

- The turndown. Part 1 of the series showed an example where the operating cost of two boilers, with the same BTUH output, would be lower with the higher turndown fire tube design. The operating cost with water tube could be overcome by using more boilers. Of course, the first cost then goes up. It cost more to install three boilers than two.

- The host of options. Many boilers have various control options, multiple input options for higher installed efficiency. The options of one boiler over another may sway your choice.

- Hydronic piping design. The primary-secondary system requires more piping and pumps. The variable primary piping design may be less expensive to install but the controls may be more complicated. The owner, your client, will not be able to “play” with this type of system.

- The representative. It is important to have a manufacturer’s representative that is available, has startup and warranty staff, trains service contractors to understand the internal boiler technology, and has the system engineering knowledge to help with solutions. R. L. Deppmann is the choice you want whether your first four choices lead to water tube or fire tube design. We have them both covered.

Next week we will explore the hydronic primary secondary piping vs. the primary variable type and some boiler limitations you may need to know about.

Part 1: Turndown Ratio in Condensing Water Tube vs. Fire Tube Boilers