Common questions we receive about Pressure Booster Systems are specifically about the pressure sensor and ASHRAE 90.1-2013 Energy Standard which is also part of the 2015 Michigan Code:

Common questions we receive about Pressure Booster Systems are specifically about the pressure sensor and ASHRAE 90.1-2013 Energy Standard which is also part of the 2015 Michigan Code:

- Do I have to put the sensor at the top of the system?

- Can I use sensorless control?

Today, the R. L. Deppmann Monday Morning Minutes will review the wording in the standard and how Bell & Gossett meets the standard. Let’s look at the wording of the Michigan Code and Standard.

ASHRAE 90.1-2013 Energy Standard for Pressure Boosters

The ANSI/ASHRAE/IES Standard 90.1-2013 Energy Standard for Buildings Except Low Rise Residential is the basis for the 2015 Michigan Energy Code. The State of Ohio has not adopted the 2013 or later version as of the first publication of this blog.

10.4.2 Service Water Pressure Booster Systems. Service water pressure booster systems shall be designed such that:

-

- one or more pressure sensors shall be used to vary pump speed and/or start and stop pumps. The sensor(s) shall either be located near the critical fixture(s) that determine the pressure required, or logic shall be employed that adjusts the setpoint to simulate operation of remote sensor(s).

- no device(s) shall be installed for the purpose of reducing the pressure of all of the water supplied by any booster system pump or booster system, except for safety devices.

- no booster system pumps shall operate when there is no service water flow.

Let’s look at each statement and review…

You Need a Pressure Sensor!

The first sentence says “one or more pressure sensors shall be used…” Unlike hydronic systems, pressure boosters will require a sensor even if the manufacturer has a program to simulate sensorless control.

In hydronic systems, we are only concerned with the differential pressure of the pump. We use a differential pressure sensor (DP) to maintain the control head. We can also use that same DP setting in a sensorless application. With pressure boosters, we use a pressure sensor (P); not a DP. As the suction pressure rises and falls, the pump speed drops or rises to satisfy the pressure. The first sentence of the section shown above clearly says we need a pressure sensor.

Your Choice to Locate the Sensor

The next sentence shown above is all about where the sensor is located. ASHRAE wants us to save the most energy. When there is more flow in the system, there is more pressure drop in the pipe. The critical fixture is most likely the farthest flush valve on the top floor. This will require the pump speed to provide the minimum pressure at the flush valve, the pressure required to lift the water due to elevation, and the pressure required to overcome the friction loss on the way to the farthest fixture.

If you locate the sensor at the farthest critical fixture, the pressure at the sensor will drop when the friction increases (more flow). The pressure at the sensor will rise when the friction loss decreases with less flow. The variable speed pressure booster pumps can react to this change.

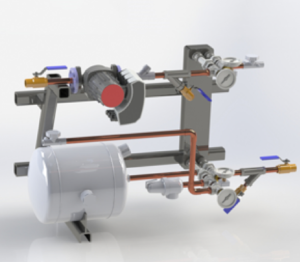

The standard reads, “or logic shall be employed that adjusts the setpoint to simulate operation of remote sensor(s).” The pump controller on some booster systems uses a quadratic equation to simulate the expected pressure drop in the piping system and adjust the speed of the pump by adding that friction loss to the pumps. This is a function we can activate in our “Best” and “Premium” Bell & Gossett pressure boosters.

With these systems you can keep the sensor on the package and still meet the standard.

Pressure Reducing Valves?

The next paragraph, b, in the 90.1-2013 standard indicates there shall be no pressure reducing valves on the pressure booster. Let’s walk through the wording. …no device(s) shall be installed for the purpose of reducing the pressure of all of the water supplied by any booster system pump or booster system,” In older constant speed systems, there were pressure reducing valves (PRVs) to reduce the pressure as the suction pressure started to rise. Today, we drop the speed and save the energy wasted across the PRVs. “All of the water” is important.

The next paragraph, b, in the 90.1-2013 standard indicates there shall be no pressure reducing valves on the pressure booster. Let’s walk through the wording. …no device(s) shall be installed for the purpose of reducing the pressure of all of the water supplied by any booster system pump or booster system,” In older constant speed systems, there were pressure reducing valves (PRVs) to reduce the pressure as the suction pressure started to rise. Today, we drop the speed and save the energy wasted across the PRVs. “All of the water” is important.

Many plumbing designs still use PRVs for individual zones to drop the pressure below the 80 PSIG limit. These PRVs may be installed with the required hot water recirculation design and equipment or you may use a packaged high rise recirculation package. The key point here is the words “all of the water”. Only part of the water goes through the PRV. The part in the zone the PRV services.

Also important are the words “except for safety devices”. These words are important If you install a variable frequency drive “bypass” starter. If there is a starter on the pressure booster, someone will use it. When they use it, the full pressure of the pump at full motor speed will be added to the suction pressure. That may become a safety issue and you would need a PRV on the pressure booster or in the main.

Turning the Pressure Booster Off

The last sentence, 10.4.2c, says when there is no service water used, we should shut the pressure booster off. This is easy to accomplish. There is no tank needed to accomplish the turning off of the system. If there is even a small leak or load, the system will come right back on. Turning the system on and off over and over meets the letter of the law but will start to cause wear on the pumps.

Many engineers use expansion tanks as a means to keep the pump off for a bit of time. You may visit our past blogs on tank selection for more information.

Bell & Gossett meets the ASHRAE 90.1 standard and provides additional features for the building owner. Why not call today for more information on how we can help choose the best solution.