Here we go again! We are starting to hear about salespeople for a competitive brand of variable speed pressure boosters advising engineers that their system “does not need a tank.” They say “My pressure booster system is different and does not need a tank at all.” I have news for you, Bell & Gossett (B&G) pressure boosters do not need a hydro-pneumatic tank. It is not the pressure booster that needs a tank. Boosters run fine without tanks. The reason we suggest a tank is to save energy during periods of low flow or when a fixture has a small leak.

Here we go again! We are starting to hear about salespeople for a competitive brand of variable speed pressure boosters advising engineers that their system “does not need a tank.” They say “My pressure booster system is different and does not need a tank at all.” I have news for you, Bell & Gossett (B&G) pressure boosters do not need a hydro-pneumatic tank. It is not the pressure booster that needs a tank. Boosters run fine without tanks. The reason we suggest a tank is to save energy during periods of low flow or when a fixture has a small leak.

How Our Variable Speed Pressure Booster Shuts Down

When there is no demand in a plumbing system, the system pressure after the pump check valves remains constant. B&G, and other brands use this opportunity to shut the pumps off. The Bell & Gossett better pressure boosters are constantly checking the setpoint pressure and if it is constant for a few seconds, it reduces the speed of the pump a fraction to see if the setpoint remains constant. It continues to reduce speed and pressure. The higher system pressure closes the check valve on the variable speed pressure booster system and after a proof time, the pumps shut down.

They stay off until there is water usage. When there is a small load, the pressure will drop and the system will come back on. There is a ramp up time but the system will maintain the pressure. The system will come on every time there is a load or a leak because water is incompressible.

Water is Incompressible

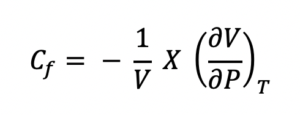

It is a known fact that water is incompressible. In reality, water is a little bit compressible. I don’t want to make this a physics class but…The compressibility formula defines the change in volume vs. the change in pressure for an isothermal condition (same temperature) as:

Cf for water is about 4.6 X 10-6 Pa-1 Applied to the real world, I have a plumbing system with no air in it and 1000 gallons volume in the piping at 80 PSIG and I take about four ounces of water out, the pressure will drop to 30 PSIG. In other words, if the booster system is off, it will not take much water to drop the pressure below what I need for a flush valve.

Try this at home or in your office. We did! In a 2 story office building, we had about 70 PSIG of pressure. We closed the city water which is the same as stopping the pump. We drained water from the system until the pressure dropped to 30 PSIG. The result was 3 ounces of water.

A major manufacturer of flush valves published a requirement of 18 GPM at a minimum of 25 PSIG. This manufacturer indicates a 1.6 liter or ½ gallon usage per flush in about 2 seconds. So I need about 32 ounces of water in an instant without dropping the flowing pressure below 25 PSIG. Based on the above test, when I take 3 ounces of water out of the system we had a 40 PSIG pressure drop.

If I don’t have the right supply of water under pressure, the valve will chatter or not flush at all. In addition, there could be noises in the system. To avoid this, the pressure booster will startup.

The pressure booster will startup anytime there is a small water demand. If there is a small leak at a fixture, the system may not even shut down.

Why Do We Suggest a Tank with a Variable Speed Pressure Booster?

Save energy:

Variable speed booster systems use variable frequency drives similar to our Danfoss brand. To avoid hunting, variable frequency drives have ramp up and down times depending on brand and the actual job site commissioning. In addition, there are proof timers to make sure the system needs to turn on or off.

All of this means that once the system turns on, it will run for a couple of minutes. That will waste energy if the load only lasted a few seconds. A tank will handle the smaller loads without the cycling mentioned above.

Minimum starts per hour:

Constant speed motors are limited to 2 to 6 starts per hour to protect the motor. In the variable speed world, the starts per hour expand to as much as 15-20 starts per hour depending on the manufacturer’s recommendation. This still requires a run time of between 2 to 4 minutes after achieving the required speed.

Once again a tank allows this time to be managed based on the storage amount.

Minimum pump flow rate:

Pressure boosters in plumbing systems often operate at very low flow rates. There is little attention paid to the minimum flow of the pump. At reduced speed, the minimum flow rate is less than the full speed published minimum flow but there is still a minimum. We are often times below the minimum when a pressure booster is at the point of turning on and off due to small load.

If the tank volume is sized correctly and the flow into the tank is controlled, the tank will assist and getting closer to the pump minimum flow rate.