There are times during the submittal phase of a project where discussions occur with the design intent as the topic. These clarifying discussions often take place because of some ambiguity or conflict in the construction documents. Over the last nine weeks we have outlined some advantages for the owner that the engineer might choose to include in their condensing boilers. Today we offer a few comments for the engineer regarding the schedules and specifications of these items.

Let’s start by making it clear that seasoned engineers may know all the items we are mentioning. There are a great many newer designers and engineers in the industry with less experience. This brief Monday Morning Minutes may help them.

The Schedule and Capacities

- The schedule should include the model and manufacturer of the basis of design. Some owners do not allow this but in general it helps the bidders understand what product was used in the piping and wiring drawings and documents. Obviously, the tag numbers and quantity of boilers currently supplied and a note regarding any expected future additional boilers should be included.

- The fluid in the system. This could be water or some type and percentage of heat transfer fluids such as glycol.

- A note here: Make sure you understand the PH and chemistry of the fluid or water quality you are asking for in other parts of the specification. The boiler and pumps’ materials of construction should align with these requirements.

- The design flow rate and design inlet and outlet temperatures along with the fluid type will provide the outlet BTUH.

- The pressure drop of the boilers at the design flow rate. You may also wish to schedule the minimum flow rate of the boiler in variable speed applications. It will help during commissioning as well as avoid issues.

- The electrical information, voltage and phase required.

- The boiler efficiency changes with the conditions. If the efficiency of the boilers is scheduled rather than specified, you will want to include a temperature and percentage load component. Example: 87% at 140°F at 100% firing rate and 95.2% at 100°F at 7% firing rate. This also makes it clear what the minimum temperature the boiler may see during operation.

- The air/fuel valve and burner turndown ratio may be scheduled or specified but should be included.

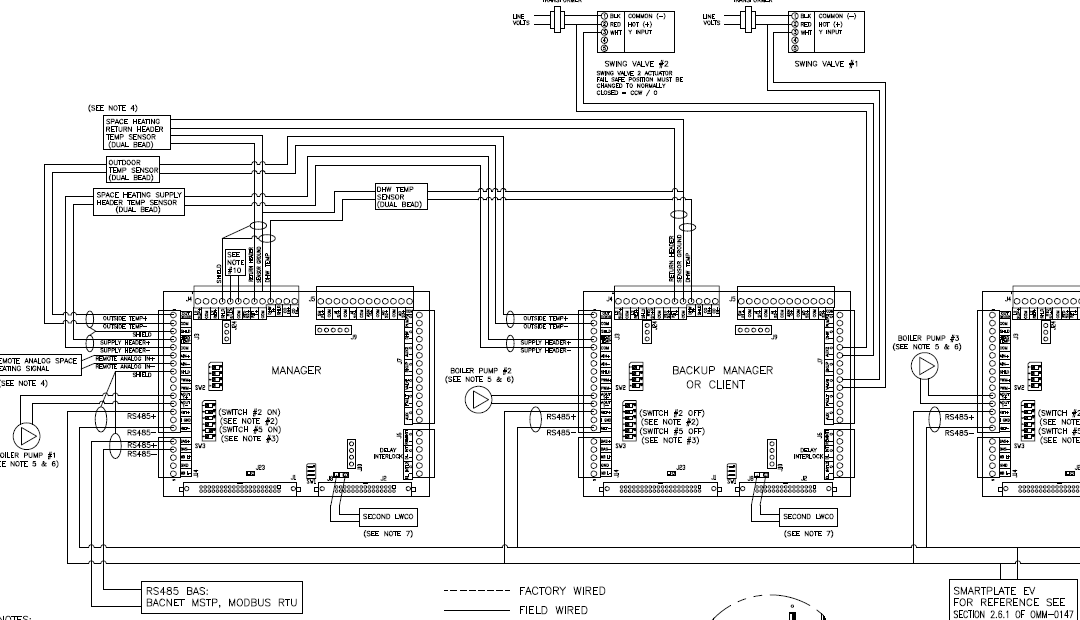

- A note regarding the primary secondary pumps and who is supplying them and controlling them should be here or in the specifications and schematic drawings. They will of course be on the pump schedule with a coordinating note.

- A note regarding the primary variable on-off valves and who is supplying them and controlling them should be here or in the specifications and schematic drawings. They will of course be on the control drawings with a coordinating note.

- The shipping and operating weight could be helpful.

- Any notes about fitting through a door size, elevator, or other entrance and exit space issues. Remember there may be a need to get a replacement boiler in the future.

- Other items the engineer may deem important.

The Specification of the Condensing Boilers

All the items and features you expect to get should be somewhere in the documents. We understand that there are coordination notes about including what may be in controls, electrical, and other places. With the fast-paced bidding process there could be items missed which causes issues for the contractor but also delays the project. Making sure the condensing boiler schedule and specification include the “extras” expected will avoid confusion.

Listing all the items in the specification could be long and, quite frankly, boring. An example of a specification can be found from the Aerco boiler website at “Aerco Benchmark Specification.” Pay attention to the controls section to see several benefits which this series has discussed.

Contact the R. L. Deppmann Company for more information.

Part 1: Condensing Boiler Specification – Part 1 – Design Efficiency

Part 2: Condensing Boiler Specification – Part 2 –Boiler Temperature Reset Made Simple?

Part 3: Condensing Boiler Specification – Part 3 – Operation at Lower Loads

Part 4: Condensing Boiler Specification – Part 4 – Variable Primary Thoughts

Part 5: Condensing Boiler Specification – Part 5 – Primary-Secondary Thoughts

Part 6: Condensing Boiler Specification – Part 6 – Variable Primary – Variable Secondary Example

Part 7: Condensing Boiler Specification – Part 7 – Variable Primary – O2 Trim Saves Your Client Money

Part 8: Condensing Boiler Specification – Part 8 – Mobile and Computer Monitoring