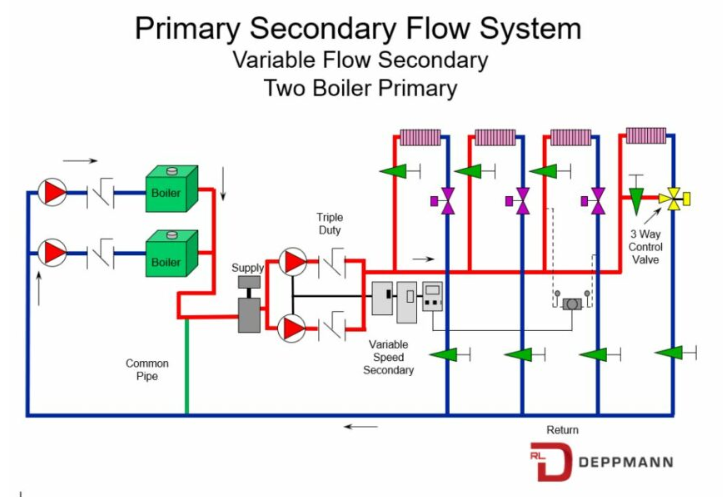

Variable Primary-Variable Secondary pumping in hydronic heating systems has many advantages when this pumping method is chosen for the condensing boiler heating system. Today we provide a video example of this type of system.

Variable Primary – Variable Secondary Video Example

In the last R. L. Deppmann Monday Morning Minutes, Condensing Boiler Specification: Primary-Secondary Thoughts, we mentioned the system with both primary and secondary variable speed pumps. Today, in the following video, we give you a real-life example to consider.

Thoughts on the Video for Variable Primary- Variable Secondary

If this was an example in a college engineering class, there could be questions. Some numbers don’t end up perfect as they do on paper. We have not discussed this with the design engineer but will take a stab at the great engineering thoughts involved.

The Design Flow Rate: The secondary flow rate was 265 GPM. The primary flow rate of the two boilers was 144 X 2 = 288 GPM. Welcome to the reality of step sizing. There will be a very slight mixing due to the differences in flows. The engineer could have matched the boiler flow to the terminal load flow of 265 GPM. By leaving the boiler flow at 288 GPM, the engineer gave the owner a bit of safety on the boiler pumps. The primary pumps have enough flow and head to take advantage of the extra 8% boiler capacity.

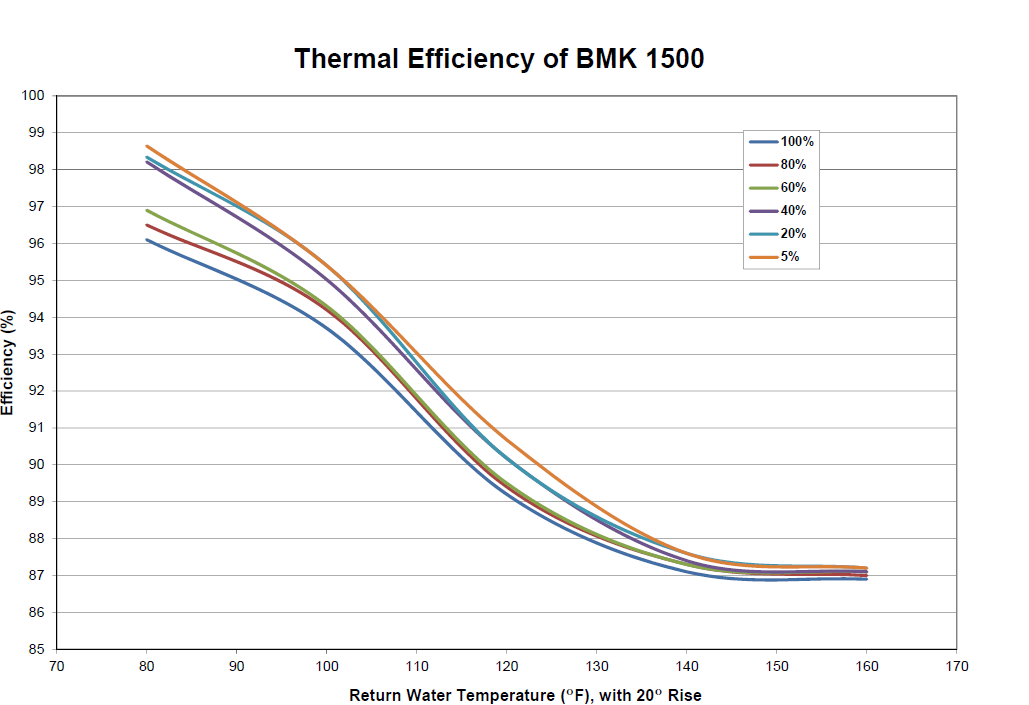

The Firing Rate vs. the Primary Flow: If you do the math…. The boiler is at 46% of the firing rate. I am going to keep the number simple for this explanation. The return temperature is 130°F. The boiler is condensed, and the efficiency is shown below.

The boiler is operating at about 88% efficiency. 1,500,000 X 0.88 = 1,320,000 BTUH. If it is operating at 46%, the boiler output would be 1,320,000 X 0.46 = 607,200 BTUH. At a 10-degree difference this would work out to about 120 GPM.

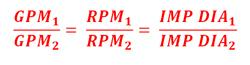

The design flow rate is 144 GPM at 13.5 feet of head. The published pump curve shows this capacity at 2743 RPM. If there was any over heading or safety factor in the 13.5 feet, the boiler would signal the pump to go slower than 2743 at design. We could use the first affinity law discussed in The Bell and Gossett System Syzer and Pump Affinity Laws.

What might the speed be at 144 GPM? GPM1 is 120. GPM2 is 144. We saw RPM 1 in the video. It was 1800 RPM.

RPM2=1800/(120/144)

RPM2 will calculate out to 2160 RPM. Another advantage of boiler controlled variable speed primary pumps is the ability to dial down the design condition and not waste energy across balance valves.

We hope you enjoyed the video. Next week we will look at another boiler controller energy saver that you may want in the specification.

Part 1: Condensing Boiler Specification – Part 1 – Design Efficiency

Part 2: Condensing Boiler Specification – Part 2 –Boiler Temperature Reset Made Simple?

Part 3: Condensing Boiler Specification – Part 3 – Operation at Lower Loads

Part 4: Condensing Boiler Specification – Part 4 – Variable Primary Thoughts

Part 5: Condensing Boiler Specification – Part 5 – Primary-Secondary Thoughts