Fire tube condensing boilers can modulate the combustion side down as the load decreases. This turndown may be just five to one (5:1) in some boilers and all the way to a whopping twenty to one (20:1) in others. Condensing boilers will return higher efficiencies when operating at part load combustion conditions. The staging of these boilers is critical to achieve higher efficiencies.

Condensing Boiler Efficiencies at Part Load

The efficiency of a condensing boiler increases when operating at less than full fire. This increase may be negligible when the return water is in the non-condensing range such as 140°F. As the system water return temperature drops, the boiler is allowed to condense even more in combustion. There is a substantial efficiency gain as the return temperature drops more and more. Let’s look at one example. We will continue to use the example outlined in parts one, Condensing Boiler Specification – Part 1 – Design Efficiency (deppmann.com), and part two, Condensing Boiler Specification – Part 2 –Boiler Temperature Reset Made Simple (deppmann.com).

Notice the large, far right blue arrow on the sketch above. The difference between efficiency at 20% input and 60% input is very small at a 140°F return. Once we apply the temperature reset strategy mentioned in part 2 of this series, now the return water temperature drops. We pick up an entire 1% when the water return temperature drops to 120°F. This jumps to 2% when the return drops to about 112°F.

Operating two boilers at 40% is better than one boiler at 80%. Operating three boilers at 25% is much better than a single boiler operating at 75%. The key is to keep boilers operating at a firing rate low enough to gain efficiency without having them staging on and off.

The Key is the Boiler Operating Controls

The boiler manufacturer knows where and when to operate the boilers. A key specification point in a larger system is the smart staging of boilers. Let’s start with the standby boiler. We do not want it just sitting there. It will be part of the operating boiler strategy.

Our example system from part 1 of the series: Three installed Aerco three million BTUH input boilers with one standby. The system load was 5,000,000 BTUH. We used 85% efficiency in the calculation to be sure the system would work with any specified boiler brand. You were fortunate or great at specification and ended up with the Aerco Boilers at about 87.7% efficiency. Your client is already winning!

At 87.7% efficiency with the coldest outdoor ai temperature (design day), The two operating boilers would produce, (6,000,000 X 0.877 = 5,262,000 BTUH) satisfying the 5,000,000 BTUH load. You enjoy a 5% safety factor in your calculations vs. output so you also win with additional output available.

All three boilers will be ready to be staged on by the controls. In general, we would set up the boilers so a single boiler would operate from 0% to 49% of its capacity. At 50%, we would stage on two boilers, each at 25% of its capacity. If the boilers drop to 20% of capacity, we will stage off the boiler. These percentages could be adjusted as the operation of the system, client’s use of the building, and the weather is clearer. The goal is to avoid cycling boilers on and off either on low load or minimum flow.

The Proof is on a Real Project

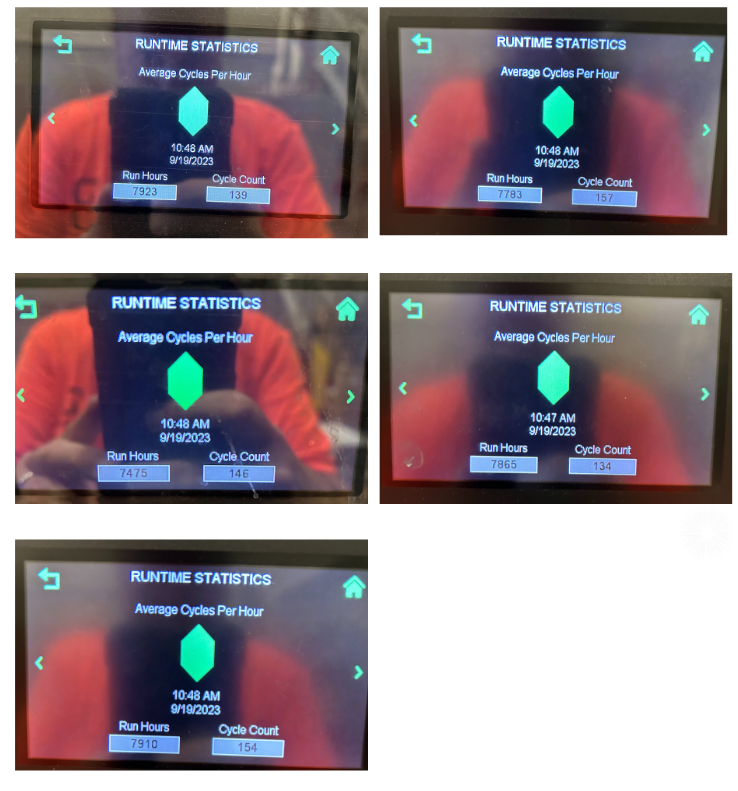

It is always easy to read what this or that can do. The real comfort level comes when things happen in a real-life situation. There is a multistory very large office space with some controlled environment labs with five Aerco 6,000,000 BTUH Benchmark boilers with Edge controllers operating a staging strategy we were involved with. Here is a recent screenshot of operating hours and number of cycles. Remember, excessive cycling of boilers wastes energy and increases maintenance time required as described in Using Part Load Heating Data and Turndown Ratios.

Wow. These boilers show run hours equal to almost twelve months of heating season operation. So, we are showing more than a year’s worth of data for five boilers. Not a small sample. On average, these boilers have only cycled about once every 2 to 2-1/2 days. Very little energy is lost with cycling.

Wow. These boilers show run hours equal to almost twelve months of heating season operation. So, we are showing more than a year’s worth of data for five boilers. Not a small sample. On average, these boilers have only cycled about once every 2 to 2-1/2 days. Very little energy is lost with cycling.

This is what a boiler system with great turndown and a great controller can do for you. Next week we will look at a trim item required for staging and meeting the energy codes.

Part 1: Condensing Boiler Specification – Part 1 – Design Efficiency

Part 2: Condensing Boiler Specification – Part 2 –Boiler Temperature Reset Made Simple?