Most boilers use flame rectification to prove that the boiler has fired. Flame rectification is a process where a low A/C voltage is applied to the flame rod, and when that flame rod is inserted into a proper flame, the voltage converts to a D/C voltage by traveling through the flame to ground.

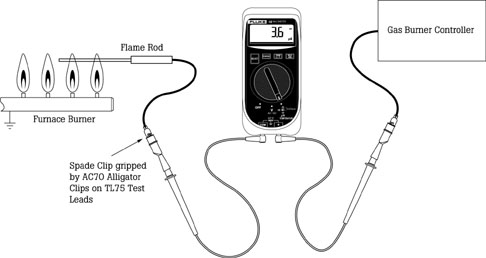

You can measure flame signal by putting your meter (capable of measuring micro amps) in line between the flame sensor and the wire that was connected to it (see picture). If you are reading anything under 5 uA (micro amps), it is likely that your flame sensor is dirty.

Most flame sensors have a coating on them to keep them clean; with this in mind, you should avoid using anything too abrasive, like heavy grit sand paper. This will wear down the coating and cause the sensor to get dirty at a more rapid rate in the future. I recommend using a 3M Scotchbrite pad to polish the sensor (see picture). The sensor needs to be cool to the touch when you clean it so it doesn’t melt the Scotchbrite pad and leave a residue on the flame rod.

After cleaning, you should reinstall the flame sensor and take another reading in order to see how much you improved flame signal.