Today’s HVAC and Process engineers may choose any number of pipe sizing programs for steam and condensate applications. Put in a load and a pressure and out pops the answer. How is the answer generated? Why is the pipe that size and can I change it? These and other questions are answered in the R L. Deppmann Monday Morning Minutes.

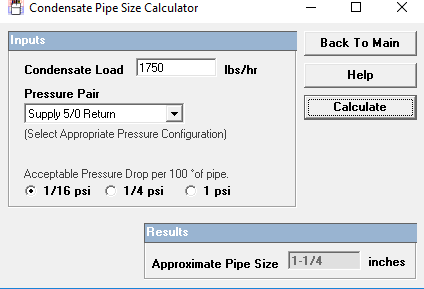

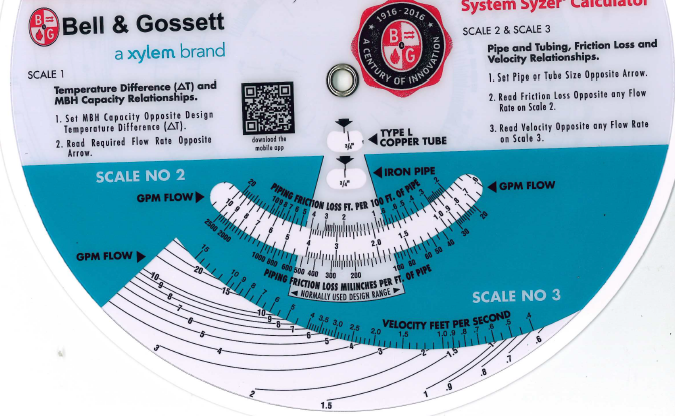

When selecting a pipe size in hydronic HVAC systems, we are concerned about GPM or gallons per minute flow rate, velocity, and pressure drop. Why can’t I just use the Bell and Gossett system Syzer? Steam condensate pipe sizing is similar but with a special nuance. Here is an example: Let’s assume we have 1750 Pounds per Hour (PPH) of condensate and we want to select a pipe size.

1750 PPH/ (60 Minutes per Hour) = 29.17 PPM

And

29.17 PPM/ (8.33 lbs. per gallon) = 3.5 GPM

If I use the System Syzer, I see that ¾” iron pipe is a fine choice in a hydronic system. The challenge in steam condensate systems comes to us from three directions. First, the motive force is often gravity, which is simply the pitch of the pipe or low pressure. Second, there’s the presence of air in the pipe. Third, steam condensate is often water at or very near the saturation temperature.

Pressure drop in steam condensate pipe: wet returns

When sizing condensate pipe it is important to identify whether the pipe is a wet return or a dry return. The key difference in a wet return is that the pipe is completely filled with condensate and the pressure drop calculations are similar to hydronic systems. The only thing we need to watch is the pressure drop. If my example of 1750 PPH or 3.5 GPM is in a wet return and I had 2 PSIG at the inlet to a steam trap and I take a 1 PSIG drop through the trap, there is only 1 PSIG plus any elevation difference as the motive force. If I use ¾” pipe, as shown above, the friction loss is about 3.3 feet or 1.4 PSIG of pressure drop per 100 feet of pipe. If the motive force is 1 PSIG and there is no backpressure, I should not have more than 70 feet of TEL (total equivalent length) or I will back up condensate into the coil or heat exchanger return pipe. An example of a wet return is the returns below the water line of the boiler or the discharge from a condensate pump.

Most condensate return pipes are “dry returns”

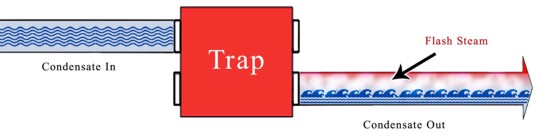

Dry returns are not completely filled with water. These returns are above the boiler water line and have a combination of water, air, and steam at various times. The pipe sizing has to accommodate all three without backing condensate into a coil.

This pipe must be sized for pressure drop at the rated flow and room for water flow (condensate), air, and flash steam.

The condensate leaving the coil is assumed to be at the same temperature as the steam that entered it. Once the hot condensate enters the lower pressure of the gravity return line, a small percentage of the liquid will flash to steam right in the pipe. We use what is referred to as a condensate pressure pair. The condensate pair gives the maximum steam pressure in the coil followed by the pressure you have in the downstream return line.

So how much volume do we need in the pipe for flash steam? Water has a specific volume of about 0.016 cu. Ft. /lb. and 0 PSIG steam is about 25 Cu Ft. /lb. That is a lot of expansion! If we do not have the room to expand, we will back up the condensate flow and even cause some steam hammer. As the steam pressure entering the coil rises, the temperature of the condensate rises and there is more flash steam.

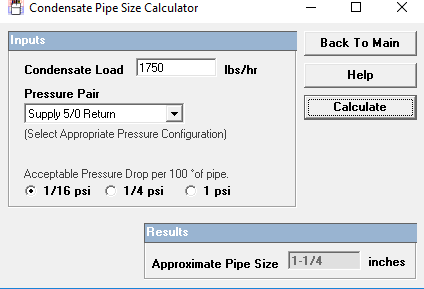

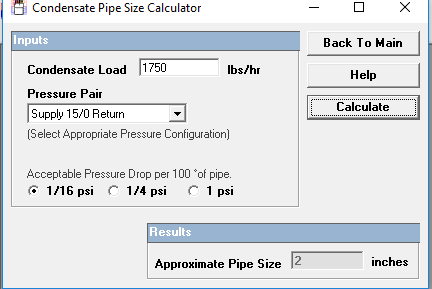

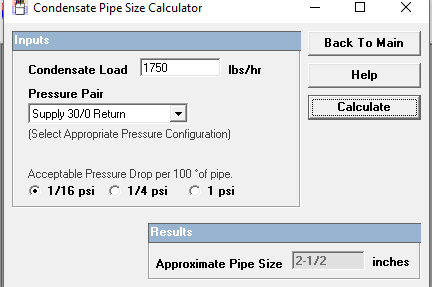

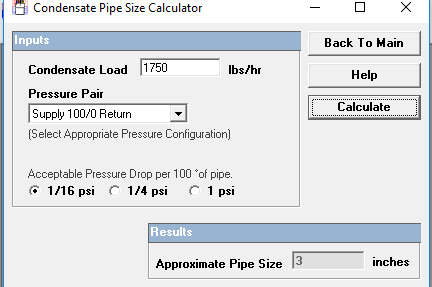

Below is a series of screen shots from the Xylem, Hoffman pipe sizing program. The capacity or flow rate is the same and the acceptable pressure drop is the same. The only difference is the pressure. Higher pressure requires a lot of room for flash steam.

If I select a pipe size based on a (5,0) pair, the program selects a pipe size large enough for the flash from the 227°F condensate down to 0 PSIG at 212°F. The 227°F is the temperature of saturated 5 PSIG steam. If I select pipe size based on a (15,0) pair the pipe diameter must be large enough to flash the condensate from 250°F down to 212°F so the pipe size gets larger. The latent energy required to flash the water into steam comes from the sensible temperature in the liquid. We’ll talk more about flash steam in a later Monday Morning Minute.

As the pressure or motive force increases, the pressure drop per 100 feet can increase but be careful. Coils and heat exchangers with modulating control valves may have significantly reduced pressures in the condensate line.

The link to this software is located on our website. As I am writing this article for publication on Feb. 13, 2017, the folks at Xylem and Hoffman are aware of a “Java” issue with the site and they are working to fix it. Please try back if you receive an error message. Meanwhile, your R. L. Deppmann sales engineer is ready to answer any questions.

Discover more on our Heat Exchanger Series below:

Part 1: Understanding Steam and Steam Heat Exchangers

Part 2: Why Use Low Steam Pressure?

Part 3: Vacuum Breakers: Steam and Steam Heat Exchanger Basics

Part 4: Condensate Drop Leg and Pipe Size

Part 7: Steam and Condensate Pipe Sizing Health Care Example