Shell and tube heat exchanger leaks can be very frustrating. Occasionally we receive a call from a frustrated contractor who swears he installed the heat exchanger properly but finds occasional leaks at the gasket.

Shell and tube heat exchanger leaks can be very frustrating. Occasionally we receive a call from a frustrated contractor who swears he installed the heat exchanger properly but finds occasional leaks at the gasket.

Steam to Water Shell & Tube Heat Exchanger Duty

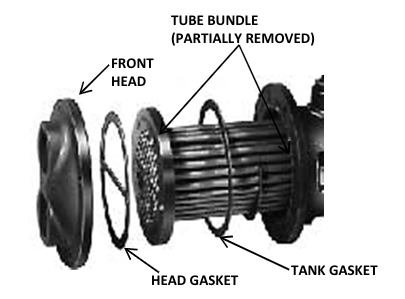

As complicated as we think it is, the steam to water heat exchanger in commercial and institutional hydronic systems has an easy job. Heat so many GPM of water from, for example, 150⁰F to 180⁰F using 10 PSIG steam. No exotic fluids and chemicals. No extreme high pressures.

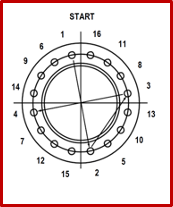

The Bell and Gossett installation and operation manual (IOM) instructs the contractor to tighten the bolts to a specific torque and in a specific pattern once the heat exchanger is at operating conditions. I assume other manufacturers have similar requirements. The same IOM clearly states that, during an operational shutdown, the hot side fluid must be shut down before the cold side. All these requirements are designed to avoid leaking or drips as the temperatures in the heat exchanger change from cold to operational temperature.

The contractor does everything right but finds occasional leaks.

Heat Exchanger Thermal Cycling

One possible issue is thermal cycling of the heat exchanger. If the heat exchanger is heated to design and then shut down over regular periods, the gasket between the cast iron heads and steel tube sheet may drip. The gasket’s “seating force” may drop due to expansion and contraction.

As the heat exchanger operates, the head, tube sheet, bolts, and gasket materials are affected by the temperature. That is why the contractor is asked to re-tighten the bolts once the operating conditions are achieved.

The heat exchanger manufacturer provides gasket material to meet the design conditions specified. Here is an example I ran into many years ago. A university built an addition with a new Bell & Gossett SU heat exchanger. The design conditions were the numbers I mentioned earlier in the blog. For some reason, at night, they shut the system down. I am not sure why they did it, but they did it. This exchanger cycled from the hot conditions to room temperature regularly. The gaskets leaked.

The Gasket Solution that Saved the Day

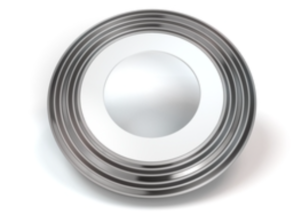

The solution was to replace the compressed fiber gaskets with Elastagraph gaskets. These gaskets combine graphite and metals to provide a gasket that responds much better to cycling. That was the solution that satisfied the university problem.

Today, Bell & Gossett standardizes on these gaskets in the 14” to 20” steam to water U-tube model SU heat exchangers. There is a large enough gasket to head surface to provide them as a type of insurance against wide temperature swings. On smaller diameter heat exchangers, these gaskets are optional and have a higher cost and delivery time.

Please be careful in specifications. Asking for “metal” or “spiral wound” gasket brands may cause issues. Not all gasket materials and types are recommended with the head, bolt, and shell materials used on the heat exchanger brands used in our industry. Make sure you coordinate the specification and talk to your local representative.