Recently, we received several requests for the “short circuit current rating” or SCCR of a packaged piece of equipment. We also received requests for the “interrupting capacity” or AIR of some parts on pump packages. These electrical ampere ratings are more important than some realize, and they are not the same thing.

Recently, we received several requests for the “short circuit current rating” or SCCR of a packaged piece of equipment. We also received requests for the “interrupting capacity” or AIR of some parts on pump packages. These electrical ampere ratings are more important than some realize, and they are not the same thing.

Before I begin, I thank Xylem, which includes the Bell & Gossett and Gould brands, for the multiple conversations and correspondence to assist me in understanding these terms and their use.

What are these terms and where do they apply?

Both SCCR and AIR are electrical ratings in amperes or AMPS. These ratings apply to control panels as well as parts and pieces in the panels. They also apply to starter panels and variable frequency drives. They DO NOT apply to pumps or motors.

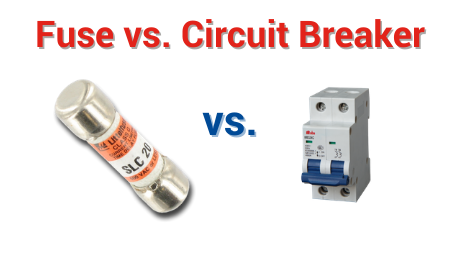

Interrupting current (AIR) applies to safety devices we normally have installed in a panel or controller. These are safety devices such as fuses and circuit breakers. It is the amount of current that can clear or go through a device without causing harm; such as an explosion.

As an example, many of the packaged pressure booster systems from Xylem are designed to have a high SCCR. They can, therefore, use fuses that have an AIR of 200kA. Higher rated fuses may be used depending on the fuse class, manufacturer, and availability.

Short circuit current rating (SCCR) applies to the entire piece of equipment. Where the AIR mentioned above applies to the safety device, the SCCR applies to the entire pressure booster with its panel mounted. I quote Michael Kubeja from Xylem when he says, “The SCCR value incorporates and factors in all the relevant Interrupting Ratings and/or SCCRs of any sub-components within the “parent” component or piece of equipment. As such, the SCCR rating of the equipment is only as large as the smallest Interrupting Rating or SCCR of all the relevant sub-components or over-current protection devices contained within”.

The SCCR rating is the weakest part of the package or panel. For this reason, the engineer normally specifies the SCCR required rather than the AIR.

In the B&G pressure booster package, the finished system will have a resulting SCCR of 65kA to 100kA, again, depending on the panel size and components used.

How does the Owner and Engineer determine the SCCR?

A packaged piece of equipment with a panel will obviously be connected to the electrical supply in the building. If we trace the electrical power back into the building, it will eventually be connected to another piece of equipment or junction where more equipment is connected. This is a “node”. What are the thousands of amps which may form at this node during a catastrophic failure electrical short circuit? This requires a study.

The owner or engineer should perform a recent Arc-Flash Study (aka Fault Current Study) to determine how much fault current is possible on the circuit at the planned node to which the Packaged product is to be connected. It is not enough for a customer/end-user/contractor to simply guess and say, for example, “give me one with 65kA SCCR” without having a real fault current value to back it up as it is possible that 65kA might not be enough protection.

The manufacturer should be supplied with the correct SCCR required prior to bidding. With this information, the manufacturer can configure the unit to have the correct SCCR and price it accordingly. The supplied product will ideally be UL Listed and as such, shall be labeled as per UL and NFPA 70 NEC requirements.

After that, it is up to the Authority Having Jurisdiction (AHJ), and the Engineer/Owner to sign-off on the proper and safe application and installation of the system in question.

There are also other extenuating circumstances where it might not be possible for the manufacturer to achieve the required SCCR value. The manufacturer given the time to analyze, can advise the specifier of any special considerations. In this case, the end-user/customer would have to take steps to install devices or other infrastructure to reduce the available fault current to a value that is compatible with what the manufacturer can provide.

Construction, Who is Responsible for What?

In the world of construction and documents, who is responsible for what? It is up to the owner of the site, and/or their contracted qualified Engineers or Electricians, and the Authority Having Jurisdiction (AHJ) to determine what sufficient SCCR rating is required for a product to be safely installed at the site in question.

The manufacturer is only responsible for clearly marking and labeling the package or electrical panel product with the SCCR rating of the given unit. The manufacturer cannot possibly know what the available fault current is for a given end-user’s installation site.

The specifying engineer should determine the required SCCR. This should be clearly indicated in the construction documents. The engineer should request the SCCR rating of the panel while working with the representative during the selection and scheduling process. Any shortfall on the SCCR should be discussed to determine whether the product can be changed or whether the engineer should make provisions in the electrical system.

The pumping package, pressure booster, sump & sewage package, or condensate handling package is normally either pre-purchased or supplied by the mechanical trades. The entire contract document set is not often provided to the manufacturer’s representative at time of bid. The contractor is frequently searching for prices under very tight time constraints. They often provide a quick email with a specification section of the product, a detail, and a schedule.

My point is simple. There is a required SCCR for every piece of equipment with a panel. That information is important and should be provided to the bidders of mechanical packaged pieces of equipment. As a representative, I would suggest the following recommendations. The mechanical engineering consultant might consider a schedule in the mechanical drawings of the required SCCR for each piece of packaged product provided by the mechanical trades. The other option is to include it in the equipment schedule. This helps avoid errors at bid time which become errors at submittal time which become errors in approval and release. Ultimately it avoids providing a client with a piece of equipment which may become dangerous.

Why Not Just Specify the Moon?

The thought may occur to specify a very large number to always be safe. This may be expedient but costly for the client who hired the architect or engineer to design the project. Here is an example using one of our products from Xylem.

For example, end-user’s site needs a 3-Phase 460 Volt Triplex booster system. Their site will be using Circuit A, and they intend to connect the booster system to Circuit A at Node D. At Node D, Circuit A can deliver 46,850 Amps (46.9 kA) of fault current. Therefore, the booster system itself SHALL (and I do mean the legal NFPA-NEC and OSHA version of “SHALL”) be rated to handle this fault current, a rating given as the SCCR (Short Circuit Current Rating).

As such, we would customize their booster panel with a fusible disconnect switch with fuses installed, sized, and ideally coordinated for the power feed to achieve a SCCR value of at least 46.9kA, which in many cases we can do starting at a minimum SCCR of 65kA. Depending on some of the other critical components we use inside the panel, we can often reach 100kA SCCR. If the engineer decides to specify 200kA for the SCCR as a standard, many of the standard components may not be able to be used.

The engineer may find that some components requested in the specification are not available to meet their own specification. A standard package with the expected budgeted price range and lead time will not apply. The manufacturer may even decide to “no bid” the request given the limited bid time.

Watch what you ask for in the panel. In general, circuit breakers with high SCCR ratings are NOT feasible, either because they do not exist, or are too cost-prohibitive, in a miniature or small form such as would fit inside the typical electrical assemblies used. Circuit breakers with SCCR ratings near 65kA (especially higher amperage units over 100A) tend to be exceedingly expensive.

Circuit breakers having a useful SCCR rating only maintain that rating if certain OTHER devices upstream (and sometimes also downstream) are of a specific type, rating, and even

In summary:

- The required SCCR should be calculated by the engineer.

- The SCCR must be provided by the engineer when selecting and specifying the packaged piece of equipment. A determination will be made how best to handle the need.

- The manufacturer can provide the “standard” SCCR which the product will be labeled but it is up to the engineer or AHJ to verify if it is correct.

- There is no need to specify the AIR once the SCCR is given.

- If the requested SCCR is too great, the packaged product may not be enough. The engineer may have to provide other electrical means for protection.

Hopefully this complicated, but important, R. L. Deppmann Monday Morning Minutes helps you make a better decision when specifying packaged products.