Maintaining the required minimum flow in centrifugal pumps is key to trouble free expectations and long life. In boiler feed applications, this minimum flow is very critical. Low suction pressure, higher temperatures, and the potential for occasional flashing are trouble enough. If we add minimum flow issues to the mix, the pump will not last very long. Today, the R. L. Deppmann Monday Morning Minute offers a quick solution to this issue.

Maintaining the required minimum flow in centrifugal pumps is key to trouble free expectations and long life. In boiler feed applications, this minimum flow is very critical. Low suction pressure, higher temperatures, and the potential for occasional flashing are trouble enough. If we add minimum flow issues to the mix, the pump will not last very long. Today, the R. L. Deppmann Monday Morning Minute offers a quick solution to this issue.

Boiler Feed Pump Bypass

In systems where multiple boilers are fed from a single pump, minimum flow can be an issue. In systems where the pump operates continuously and a boiler feed control valve modulates to feed the boiler, minimum flow can be an issue. Maintaining minimum pump flow becomes even more important in higher pressure applications.

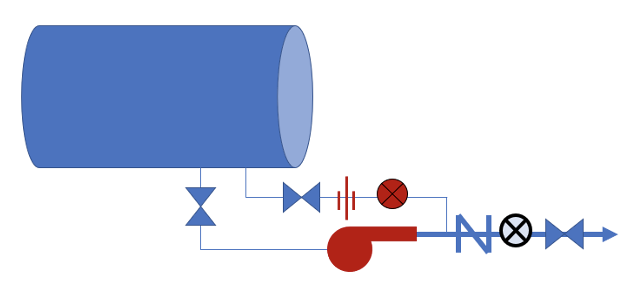

The minimum flow is normally handled by a combination of three-way valves and bypass valves in a hydronic system. In steam boiler feed systems, the bypass valve is the option of choice. The bypass is piped back to the tank with a throttling valve.

The choice of a bypass throttling device is key. If a ball valve or globe valve is used, there is no way to measure the flow. Some engineers use a Bell & Gossett circuit setter. The valve can handle temperatures up to 250⁰F and the pressure is no problem. The materials of construction are more suited to hydronics. A major concern is the aggressive nature of the feedwater and the readout probes. The high temperature of condensate is also a concern so we recommend owners read the manufacturer’s IOM for precautions about being burned.

In these applications, I prefer a fixed orifice, or a Griswold threaded mini automatic flow control valve without temperature readout probes.

Fixed Orifice in the Bypass

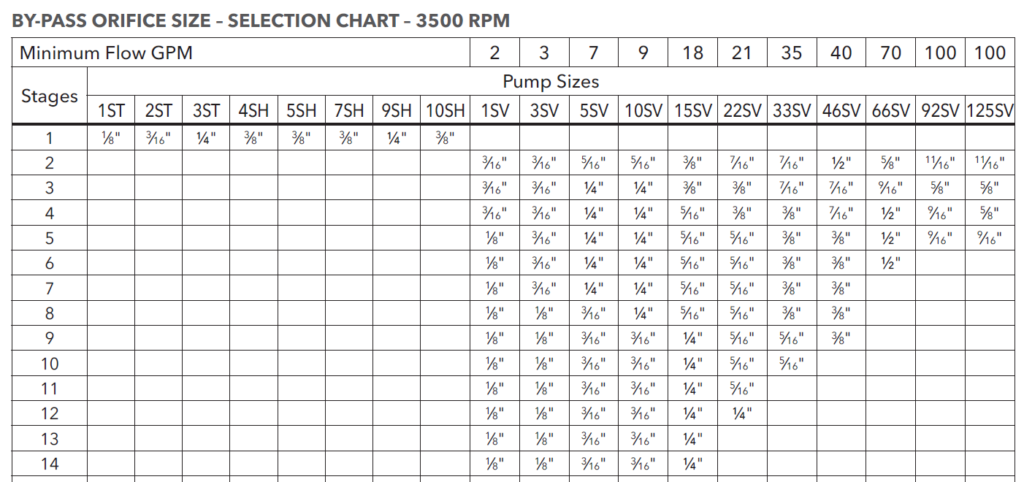

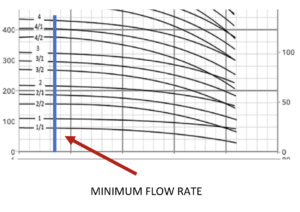

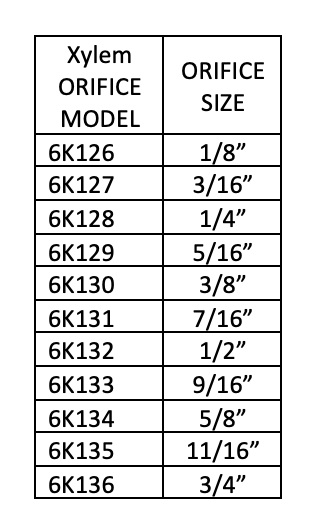

Bell & Gossett or Gould eSV pumps have an optional fixed orifice fitting for the bypass application. We know the minimum flow rate. The bypass is piped from the pump discharge back to the tank. The pressure differential required is the pump head at the maximum motor speed at the minimum flow rate and is found on the pump curve. Simply choose the orifice fitting from the charts below.

Chart from Xylem literature TDBOILEReSV R1 dated July 2017. Model numbers are B&G eSV boiler feed pumps.

Design Flow Rate of the Pump

Once you select the required flow of the boiler or boilers being served, do not forget to add the minimum flow which will be a constant bypass. Example: The pump flow rate based on the boiler load is 48 GPM. The pump requires 9 GPM of minimum flow. The system is designed to operate a single pump constantly and modulate the flow based on boiler demand. The pump should be selected for 48 + 9 = 57 GPM.

Piping of the Bypass

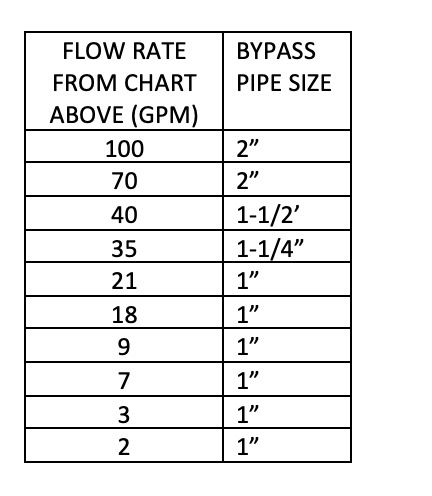

The bypass piping should be sized for the minimum flow rate and reduced, if necessary, in and out of the orifice fitting. The bypass should include a service valve at the tank and a union. This, coupled with the pump inlet service valve, will allow service without shutting down the other pumps.

The pipe should be steel, and the weight should match the service. If the pipe is under 10 feet long from the pump discharge back to the pump, use this chart for pipe size which will keep the velocity under10 feet per second (fps). The minimum pipe size should be the size of the orifice or 1”.

Variable Speed and Bypass Minimum Flow

The beauty of the orifice over the Griswold valve comes in variable speed applications. The flow varies proportionally to speed. As the speed changes, the minimum flow requirement changes, and the flow through the orifice will also change. Just size the orifice as if it was constant speed and that orifice flow rate will vary with the changing speed.

The Griswold valve is great at constant speed bypass flow rate. In variable speed systems, the speed changes and the pump head drops. With the Griswold threaded mini, this will result in the valve opening to maintain the original design minimum flow. This is less desirable than the orifice in this application.

Next week, the R.L. Deppmann Monday Morning Minutes will turn to packaged systems and the SCCR value. Not sure what SCCR is? Read about it next week.