Primary – Secondary piping is recommended with most water tube condensing boilers. Once the boilers have turned down to the lowest firing rate, cycling will occur. Today the R. L. Deppmann Monday Morning Minutes will look at the bridge piping and the cause of the cycling.

Primary – Secondary piping is recommended with most water tube condensing boilers. Once the boilers have turned down to the lowest firing rate, cycling will occur. Today the R. L. Deppmann Monday Morning Minutes will look at the bridge piping and the cause of the cycling.

Primary – Secondary Principles

The principle behind this piping arrangement is centered around keeping an extremely low-pressure drop in the common pipe between two pumped systems. This low-pressure drop will assure little change in the primary flow rate while the secondary system flow rate varies.

This allows the boiler loop to have a constant flow rate while the secondary loop flow is variable. As the secondary flow rate is reduced, the primary flow rate remains constant. The burner BTUH turns down as the load and secondary flow turns down. Since the primary flow rate remains constant, the variable is the rising return temperature to the boiler.

While the boiler burner can turn down, the supply temperature from the boiler remains constant at the set point. Once the burner is at its minimum and the secondary load continues to drop, the supply temperature cannot be maintained and starts to rise. This will start the cycling of the boiler.

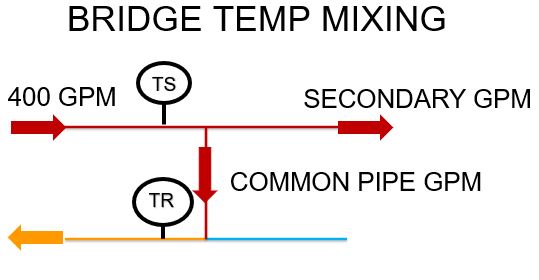

Primary – Secondary Bridge Mixing

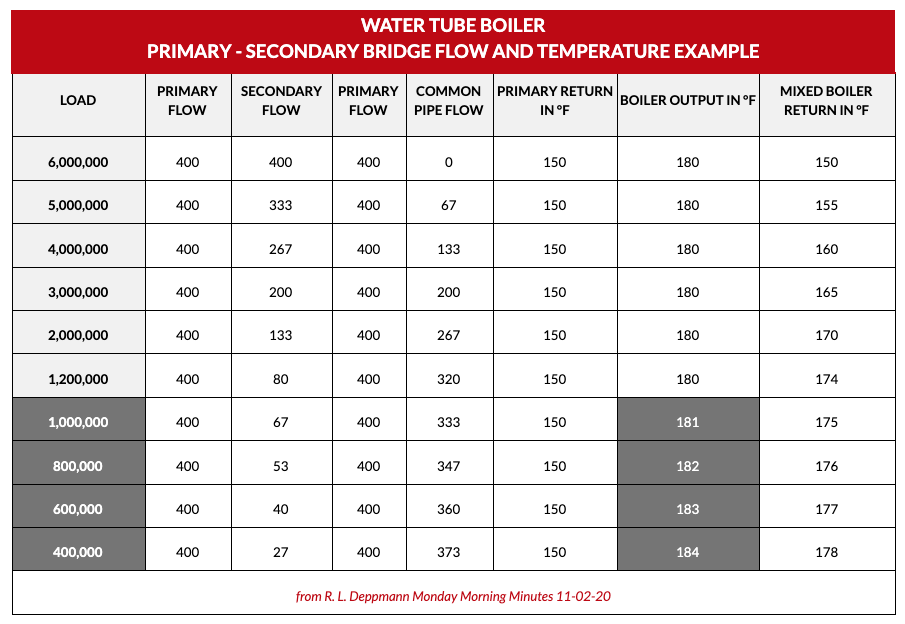

The table below shows what is happening at the primary-secondary bridge.

This example shows a single 6 million BTUH boiler with a 5 to 1 turndown ratio and a 30 °F ΔT. This always leaves us with a primary flow rate of 400 GPM through the boiler. This example does not reduce the numbers for boiler efficiency to keep the numbers simple.

The dark gray highlighted loads are operating below the minimum burner turndown load. At this point, the supply water temperature would attempt to raise the outlet temperature which is also highlighted. Since the boiler is set for 180°F outlet, the boiler will turn off. It will not turn on until the lower, start, temperature is reached. This start or “on” temperature, in this example, would be 170°F. Once the boiler has completed the purging cycle, the boiler will turn back on.

Imagine how often this would happen if the boiler could only cycle to 50% of the load.

Imagine how quickly the boiler would overshoot the outlet temperature if the flow dropped quickly and significantly on the secondary side.

These are real problems and if the system has these characteristics, there is a solution. This will be the subject of the next R. L. Deppmann Monday Morning Minutes.