Last week we reviewed the types of steam humidifiers normally supplied in building HVAC systems. Creating the steam is simply the first step. Now we have to disperse the steam into the air. This post reviews some humidification dispersion methods of building steam within isothermal humidification.

The engineer may choose from a variety of dispersion methods in the HVAC system. The choice normally depends on whether the steam is being release to the room or into the duct.

Dispersing Pressurized Steam Humidification Directly into an Area

If the requirement is to send the steam directly to a large area, Dri-Steem offers a fan-assisted assembly that’s mounted to the humidifier. This is an ideal application in spaces where there is limited ductwork. Warehouses and assembly areas come to mind.

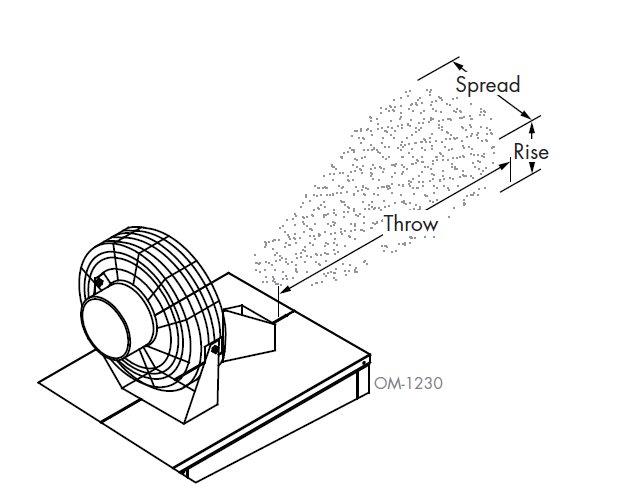

Shown below is the product and the non-wetting areas. Note that the installation should be in a place with no equipment or stock in the dispersion area. For example, if the space is 60°F with a 40% RH requirement, a 250 PPH humidifier fan will have a 16’ throw with a 9’ spread and rise. Placing the humidifier high in the area and in aisle areas would be a great use of this product type. This fan dispersion may be mounted directly to a gas-fired or electric humidifier generator, or used with boiler steam as the source.

Although fan dispersion may work well in warehouses, they would be objectionable in an office space.

Dispersing Pressurized Steam Humidification into Ductwork

The most traditional use of pressurized boiler steam for humidification in buildings is to introduce the steam into the ducted air stream. The most basic method is the single tube, as shown below. The tube seems simple enough but it is much more than a simple piece of pipe.

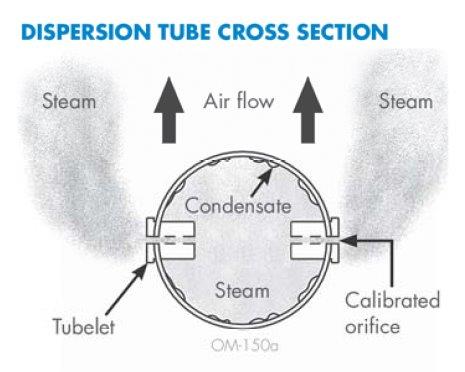

Last week, we explained how this simple humidifier works. One specification suggestion for this type of humidifier distribution is calibrated orifice tubelets. It would be simple to just drill a series of holes in the pipe, but the use of calibrated orifice tubelets gives two advantages.

First, a simple hole would cause condensate to form and drip down the tube and into the duct. The tubelet allows any condensing to occur when the steam enters it, which is still in the tube.

Second, similar to a direct return hydronic system, the liquid takes the path of least resistance and needs to be balanced. There will be more steam coming out of the first tube than the last tube. The calibrated orifice tubelet provides a greater opening diameter at the end of the tube then at the beginning and balances the steam flow. This assures an even distribution of steam in the air, which again reduces wetting.

Using a single tube for distribution does have a drawback. The absorption distance, or length of straight duct before a terminal or turn, is very long. Similar to the fan distribution, the absorption distance is many feet. To reduce this issue, the engineer may look to multiple tubes.

The multiple tube direct steam injection distribution assemblies spread the steam over many tubes and reduce the absorption distance to a few feet. Each tube operates the same way as the single tube unit, but there are just more of them.

One word of caution: these units are often shipped in pieces, which requires field assembly by the contractor. The prudent engineer would make this note on the detail to avoid confusion later in the contraction process.

Condensate Handling with Pressurized Steam: Multiple Tube Humidification Dispersion

Although most of the steam is dispersed into the air, there will be steam condensate in these humidifiers caused by warmup and maintaining the temperature of the jacket in the cooler air stream. This condensate has the steam pressure behind it and may be lifted to a condensate return main using an inverted bucket trap. Remember that the rule is:

1 PSIG OF PRESSURE WILL LIFT WATER ABOUT 2 FEET

So if a single tube humidifier has 3 PSIG steam pressure at the valve, the maximum lift out of the trap is 6 feet. The 6 feet may be reduced by control valve pressure drop and steam trap loss, so work with your Dri-Steem representative for the exact lift available.

Most applications of humidification today require tighter absorption distances. Next week we’ll address panel type humidification dispersion methods.