I have written a great deal about the minimum flow rate requirement in centrifugal pumps. We recently received an email from an engineer who was looking for a fast answer on the minimum flow requirement for a chilled water variable flow system she was designing. I thought this would be a good time to simplify a quick checklist for finding the solution.

I have written a great deal about the minimum flow rate requirement in centrifugal pumps. We recently received an email from an engineer who was looking for a fast answer on the minimum flow requirement for a chilled water variable flow system she was designing. I thought this would be a good time to simplify a quick checklist for finding the solution.

Variable Speed Minimum Pump Flow Rate

Pump manufacturers will publish a minimum flow rate for their pump based on many different criteria. The flow rate may be determined using the Hydronic Institute Standards (HI). This minimum flow may also be the engineered solution due to the pump suction energy and concerns about the life of the pump. Regardless, the manufacturer should be able to give you the GPM minimum for a specific pump at a specific nominal speed.

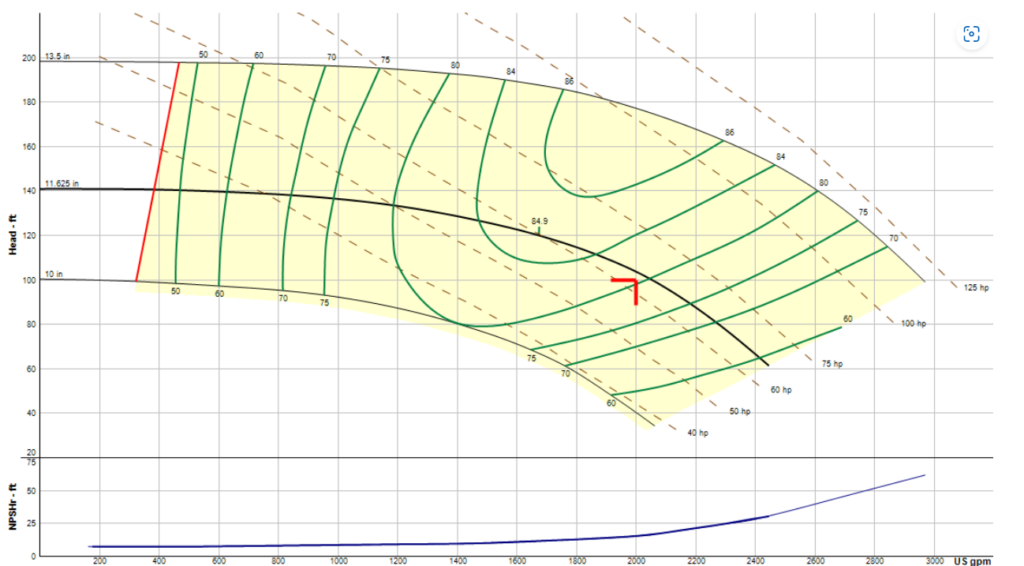

Here is an example constant speed pump curve:

Notice the red line on the left of the curve. We will round it to 400 GPM. It is the minimum suggested flow rate that Bell & Gossett publishes for this 2000 GPM at 100-foot, 1770 RPM pump. A 20% minimum flow is a standard for many pumps.

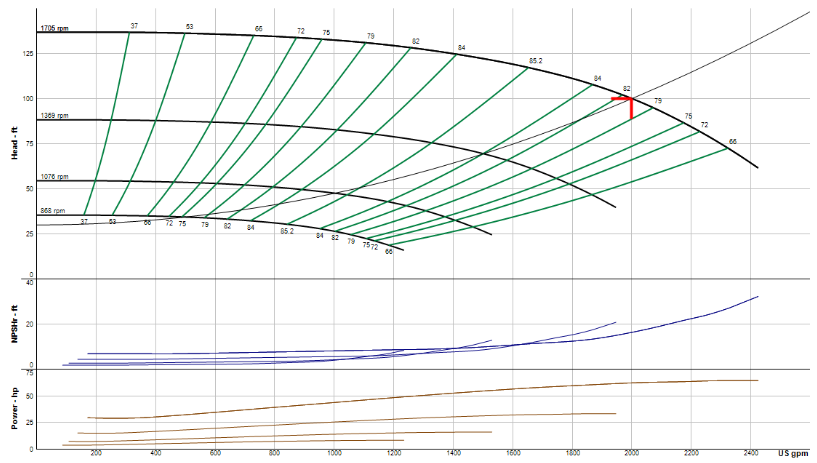

When this is a variable speed, the minimum flow rate will be less. The variable speed system curve will depend on the control methods and minimum control head. It is reasonable to assume the pump speed will drop with the demand requirement in the chilled water system. Here is the same 2000 GPM at a 100-foot variable speed curve with the control curve included.

The minimum flow rate red curve is not shown here. We know it was about 400 GPM at full speed. The minimum flow rate of the pump is affected by the speed of the pump. To determine what the minimum flow rate is at the lowest speed we must first determine the minimum speed. The control curve above shows the minimum speed at about 850 GPM. The math to determine the minimum flow at 850 GPM is simply the first affinity law. Check out our Minimum Flow in Variable Speed Pumps for Building Hydronic HVAC Systems (Part 1) for more detail. The minimum flow rate in this example at 850 RPM is just under 200 GPM.

System Minimum vs. Pump Minimum Flow Rate

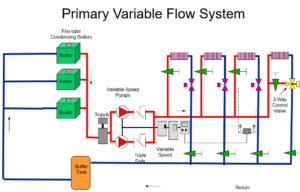

The engineer, mentioned at the start of this blog, asked for the system minimum flow rate. My next question was about the chillers. Is there a standby chiller? The answer was no. So, we have three chillers for a total of 2000 GPM.

My next question was confirmation of the assumption that when the pump was at minimum speed, only one chiller would be operational. It seemed logical but I asked to confirm. The answer was yes. So, what is the minimum flow rate through the chiller? The answer was 330 GPM. If the chiller requires a minimum flow rate of 330 GPM, that is the system minimum flow rate.

“In most primary variable flow chilled water systems, the chiller minimum flow rate is greater than the pump minimum flow rate.”

The engineer should do the calculation of any system component for minimum flow rate, whether it is the chiller, the pump, or some other component. That said, the chiller is usually the deciding device.

How do you create the minimum flow of 330 GPM in the system? Some options are shown in the Minimum Flow in Variable Speed Pumps for Building Hydronic HVAC Systems (Part 2) and Solving Minimum Flow in a Primary Variable System (Part 3) blogs.

There are many methods but my overall go-to is a mix of three-way valves on coils out in the system. This allows a precise minimum flow rate in the balanced system. It also keeps the system piping cold enough so there is no delay when there is a call for cooling increases in the system.