We often receive requests for larger commercial reverse osmosis (RO) water systems. RO systems are advantageous in humidification systems where water quality is challenging. We also see these systems in steam boiler makeup and process systems. Today we introduce a system and offer a few tips for engineers when selecting a reverse osmosis system.

We often receive requests for larger commercial reverse osmosis (RO) water systems. RO systems are advantageous in humidification systems where water quality is challenging. We also see these systems in steam boiler makeup and process systems. Today we introduce a system and offer a few tips for engineers when selecting a reverse osmosis system.

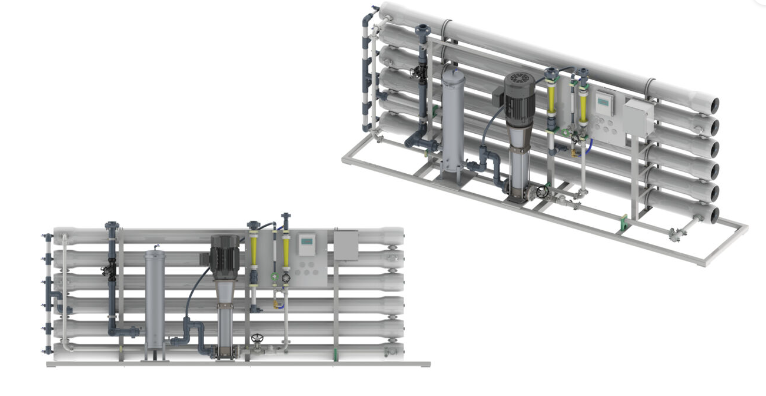

Lync by Watts Series WQ-RS Reverse Osmosis Systems

The Lync packaged WQ-RS reverse osmosis systems have capacities from 3,600 gallons per day (GPD) all the way up to 172,800 GPD or 120 GPM depending on supply water condition and temperature. These capacities are based on inlet water temperature of 77°F, 1000 ppm of solids, SDI (Silt Density Index) of less than 3, and a pH of 8.0. These packaged systems are successful in practically eliminating the presence of dissolved solids in the water, such as salts, and toxic metals. In fact, they have a minimum 95% average ionic rejection of solids.

The system includes a digital controller for ease and accuracy. Also included is the membrane auto-flush system.

Outlet Storage Tank

The RO system sized for maximum instantaneous demand can get expensive and dimensionally large. Most RO systems use a storage tank to handle these peak demand flow rates. The tank is normally non-code, vented, and poly or plastic.

A stainless-steel pump like our Bell & Gossett eSV simple booster systems is used to pump and pressurize the downstream system. The system could be variable speed or constant speed depending on the application. Point of use Pressure Booster Systems will be engineered to meet the requirements of your design.

Capacity and Water Temperature

The engineer should verify capacities for the range of water temperature expected. The Lync by Watts WQ-RS reverse osmosis system’s supply water should never be above 100°F. The capacities of most RO systems are based on a given inlet temperature. The cataloged capacity for Lync is based on 77°F. This is fine in the deep south but what about Michigan and northern Ohio? All manufacturers will be able to give you a capacity multiplier based on temperature.

Assume you select the 3,600 GPD system but the supply temperature will be 50°F in the winter when you are using the maximum water volume for humidification. What would the capacity of the Lync model be at this lower temperature? The published IOM shows a multiplier of 0.64 at this temperature. The capacity of the 3,600 GPD model would be reduced to 2,304 GPD at this supply temperature.

Pre and Post-RO Water Treatment

Pre-treatment of the water supply is important. Many chemicals found in potable water are harmful to the RO system membranes. No free chlorine is allowed. The incoming water should be softened to less than 1 grain per gallon of calcium carbonate. For pre-treatment, we would look to use microfilters, carbon filtration, and softener/anti-scale solutions. With clean treated water entering the RO equipment, it will generate more efficiently and reduce additional maintenance compared to untreated water.

The outflow from the RO system may also need treatment. As part of the RO process, the water’s pH level will drop and may have an ill effect on piping and equipment downstream. This would entail using a calcite filter to increase pH back to acceptable levels.

These conditions and the solution will vary based on the water chemistry of the supply. Give us a call to discuss this further.

Watch the Drain Design Near the RO Filters

One more thing to keep in mind. Note that you must deal with the drain water. The drain water carries the impurities away to be disposed of. A large volume of flow is used to keep the system clean. The drain may be required to handle 1.5 to 3.0 times the productivity GPM of the RO system. This is a drain capacity you do not want to forget to check. Call the RO system representative and get the exact drain capacity required.

R. L. Deppmann is ready to assist you in the selection and the various system components suggested based on the water conditions being supplied. Contact us to get more information for your project.