The last article, in the R. L. Deppmann Monday Morning Minutes, presented the cold fill pressure calculation needed for the expansion tank calculation. Another piece of information needed is the maximum pressure at the tank.

Maximum pressure in a hydronic system depends on a number of variables. Let’s look at a few examples to make a point. This week we will look at example one.

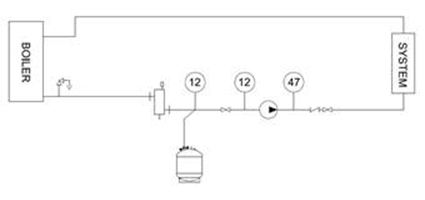

EXAMPLE ONE: Figure 1 shows a one line diagram of a heating system with a boiler and pumping system. Let’s assume we have a one story building and the heating system is only 15 feet high with a 180 degree supply temperature. Let’s also assume that the pump has a capacity of 100 GPM at 80 feet at design. We selected the Bell and Gossett series 80-2X2X9.5 inline pump with a 5 HP non-overloading motor.

Using last week’s article, we know the minimum cold fill pressure is 10.5 PSIG. Since the B&G B7-12 pressure regulating valve is factory set at 12 PSIG so let’s be smart and set of cold fill pressure at 12 PSIG rather than 10.5.

Let’s assume the boiler has a 30 PSIG relief valve. B&G ASME pressure relief valves do not pop open at the set pressure, instead, they “weep” just before the setting switch has the advantage of keeping the water loss to a minimum when we approach the set point pressure. We will take the 30 PSIG relief pressure and subtract 10% to get the maximum pressure for tank sizing, giving us 27 PSIG.

Let’s look at what is happening on the pump discharge. The maximum pressure differential the pump can do is 90 feet or about 39 PSIG at shutoff. If the maximum operating pressure in the tank is 27 PSIG and the maximum the pump can add to that is 39 PSIG, then the maximum pressure in the system is at the pump discharge at 66 PSIG.

Why did we do this last calculation? Most commercial and industrial systems have working pressures of 125 to 150 PSIG. The 66 PSIG is clearly less than those pressures; therefore, it’s fine. What happens if there was a piece of equipment with a maximum pressure of 60 PSIG downstream of the pump? Your 66 PSIG design would exceed the working pressure of the downstream piece of equipment WHICH YOU SPECIFIED OR SELECTED. The time you would find out about this would be long after the equipment was purchased and installed. This is an embarrassing and costly error. I suggest you get in a habit of always calculating and recording the maximum pressure at the pump discharge.

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles