Maximum pressure in a hydronic system depends on a number of variables. Last week we used an example to introduce the maximum pressure at the expansion tank. Let’s look at a couple more examples.

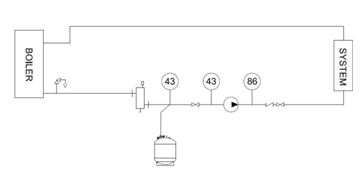

EXAMPLE TWO: Figure 1 shows a one line diagram of a heating system with a boiler and pumping system. Let’s assume we have a SIX story health care building and the heating system is 90 feet high with a 180 degree supply temperature. The pump and boilers are on the first floor. The BRYAN boilers selected come with 125 PSIG relief valves. Let’s also assume that the pump has a capacity of 800 GPM at 100 feet at design.

Our cold fill pressure will be:

90÷2.31=39 + 4 = 43 PSIG

The owner is interested in a durable pump which will last a long time and with little maintenance or repair in its expected 30 year life. You selected a B&G VSX-VSC-4X6X10.5A with a 30 HP non-overloading motor.

This pump has a design of 100 feet or 43 PSIG and a shutoff of 110 feet or 48 PSIG.

If our maximum design pressure in the system is 125 PSIG, then the maximum pressure we could have at the tank is: 125-48= 77 PSIG

Allowing a 10% safety factor on the maximum pressure gives us a tank maximum of 77 X .9 ∼ 69 PSIG so our tank will be selected for a fill of 43 PSIG and a maximum of 69 PSIG

ONE MORE THOUGHT: Remember, even though the calculations allow a high maximum pressure, you may choose to use a lower pressure. Higher pressures in systems may cause leaks or stress equipment. In addition, if you are using glycol, threaded connections at higher pressures will be tough to seal when filling the system.

Example: Assume you have a chilled water system with a tank fill pressure of 12 PSIG and a possible maximum of 80 PSIG. The tank may be very small anyway, so why not try dropping the pressure and see what happens.

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles