7 Tips to Save on Labor Hours in Hydronic and Steam Systems Building Projects

R.L. Deppmann takes this opportunity to thank the fitters, plumbers, and electricians who take such special care to properly install products we provide. Our doors are open, and the phones are active to continue to answer questions from the “field” which is also known as the “real world”. Labor hours can be hard to come by these days. In honor of this year’s Labor Day on the 7th, we offer 7 tips to avoid wasting labor hours on building projects.

R.L. Deppmann takes this opportunity to thank the fitters, plumbers, and electricians who take such special care to properly install products we provide. Our doors are open, and the phones are active to continue to answer questions from the “field” which is also known as the “real world”. Labor hours can be hard to come by these days. In honor of this year’s Labor Day on the 7th, we offer 7 tips to avoid wasting labor hours on building projects.

Tips for Pump Installation Savings

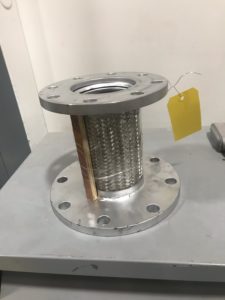

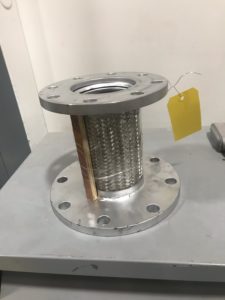

Reducing Flexible Connectors

|

|

| Pump discharge connections are normally one or two pipe sizes smaller than the valves and piping. The transitions can be expensive and dimensionally long in an area where space is at a premium.

Reducing flexible connectors such as the Metraflex RMF and RSS models will help keep the transition compact. |

|

Bob-Co Gauge Packages

|

|

| Bell and Gossett (B&G) has taught for years that pump readouts should use a single pressure gauge to reduce the inaccuracy from the differential pump readings.

The Bob-Co pressure gauge kit provides pump suction discharge and even strainer inlet connections which saves all the headache of turning copper tubing and fittings. |

|

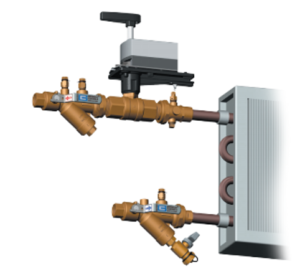

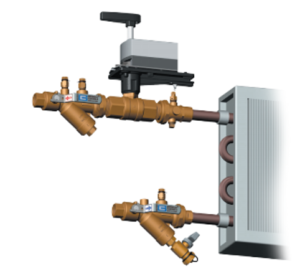

Terminal Unit Coil Piping Packages

|

|

| Not much of a secret today but Griswold and Bell & Gossett coil piping packages save space and labor by combining valves and fittings into a simple two- or three-piece installation.

|

|

R.L. Deppmann Glycol Installation

|

|

| Rolling 55-gallon drums around a project site can be tough and time-consuming. On top of that, pumping glycol into the system while removing air may involve multiple people and possibly days of effort.

Deppmann has a solution that will save time, risk, and money while ensuring the proper glycol percentage is installed. |

|

Condensing Boiler Polypro Venting

|

|

| CPVC vent glue-up can add labor and time. AL429 stainless steel venting is very expensive. Many condensing boiler manufacturers will allow polypro as a material for venting.

If local codes allow the use of polypro venting material on condensing boilers, it is worth looking at.

|

|

Steam to Water Heat Exchanger Steam Connections

|

|

| The steam piping to steam to water heat exchangers such as the B&G SU series can be large.

Manufacturers have standard published minimum steam connection sizes for the heat exchangers. Often there is an option at very low cost to change that size to match the pipe size.

Ask, prior to submittal, if the steam pipe size may be changed to avoid large transition costs.

|

|

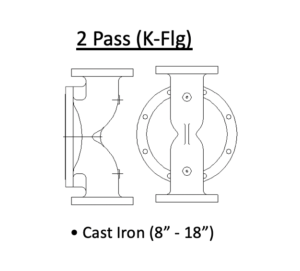

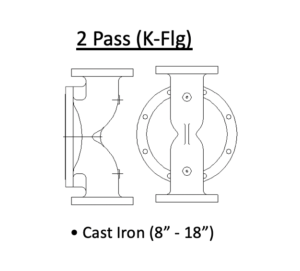

K Head Option on Shell and Tube Heat Exchangers

|

|

| Many shell & tube heat exchangers have standard threaded connections on the tube or water side of the unit.

The contractor must add elbows to offset the piping for tube pull clearance.

There are head configurations that assist with this clearance. Worth asking the question.

|

|

If you want more information on any of these options, just drop us a note or call our customer service department. Next week, the R. L. Deppmann Monday Morning Minutes will look at steam traps and control valves.

R.L. Deppmann takes this opportunity to thank the fitters, plumbers, and electricians who take such special care to properly install products we provide. Our doors are open, and the phones are active to continue to answer questions from the “field” which is also known as the “real world”. Labor hours can be hard to come by these days. In honor of this year’s Labor Day on the 7th, we offer 7 tips to avoid wasting labor hours on building projects.

R.L. Deppmann takes this opportunity to thank the fitters, plumbers, and electricians who take such special care to properly install products we provide. Our doors are open, and the phones are active to continue to answer questions from the “field” which is also known as the “real world”. Labor hours can be hard to come by these days. In honor of this year’s Labor Day on the 7th, we offer 7 tips to avoid wasting labor hours on building projects.