Last week, we used an AHU unit system example which showed the advantages of reducing the return water temperature at design, as well as, raising the delta T. The AHU unit example ended up with 1,700,000 BTUH with 85 GPM from 160°F to 120°F. Today, we will continue to look at terminal units, with the goal of increasing the delta T and lowering the return water temperature for the other terminal types in our example system.

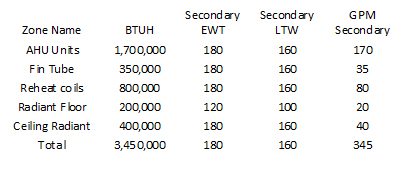

The balance of the terminal types, in our example are: reheat coils, fin tube, ceiling radiant and floor radiant systems. Let’s assume in this example the loads respectively are 800,000, 350,000, 300,000, and 300,000 BTUH. Including the AHU system, the total BTUH is 3,450,000. If we used a 180°F EWT with a 20°F delta T, the secondary system pump would have to be 345 GPM using 5” or 6” pipe.

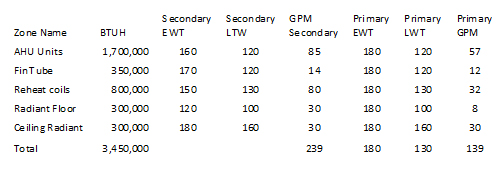

Reheat coil selections normally require the leaving air side temperature below 90°F with limits on the fins per inch of the coil.* Changing to a 150°F supply with a 120°F return, takes some additional selection time, but will result in a more efficient hydronic system.

Fin-tube selections, with velocities below 3 FPS, require more fins per inch which is relatively inexpensive. As long as we keep a reasonable average temperature, changing the delta T will work fine. In our example, we could change to 170°F supply with a 120°F, giving us an average tube temperature of 150°F.

With ceiling radiation we pay a huge sizing and cost premium when we change the average temperature, so we will keep it at 180°F supply and 160°F return.

The floor radiant system is designed to take lower temperatures and would require a mixing valve, if we supply 180°F, so we will use a design of 120°F to 100°F.

Let’s change the temperatures and see what type of boiler delta T we can achieve. The following table summarizes our design. (I rounded to the nearest whole number on the chart)

BEFORE

AFTER

What have we gained? The load obviously remains the same, but the flow rates are lower and we can use smaller pipe sizes, smaller pumps, and lower horsepower. The return water temperature is 130°F, at design, so we are taking advantage of our condensing boilers at design. When we apply the reset schedule to this system, the efficiency will be even greater.

Next week let’s take this example and design the primary secondary bridges.

High Delta T Hydronic Heating Systems Series:

- Part 1: Primary Secondary Tertiary Systems for High Delta T Hydronic Heating Systems

- Part 2: How to Increase the Delta T in Hydronic System Design

- Part 3: Increasing Delta T and Lowering Water Temperature in Hydronic Heating Systems

- Part 4: Maximizing Delta T in Boilers

Thank you for using products sold by R. L. Deppmann Company in Michigan and Ohio!