How can you increase the operating efficiency of your condensing boiler heating system? This question was raised in the last R. L. Deppmann Monday Morning Minutes. The condensing boiler provides high efficiency operation when the return water temperature is low. In fact, the lower the return water temperature we achieve in the system, the higher the efficiency. In this second article of our four-part series on Condensing Heating System Efficiency, we take the first design suggestion to improve efficiency (from last week’s article) and look at the system temperature differential or ΔT.

Traditional Hydronic System Design

Often in system design we default to a 180°F supply temperature and a 160°F or a 150°F return temperature. In these systems, we rely on outdoor reset systems to lower the supply and return temperature in warmer weather. We will cover outdoor reset schedules in detail in later articles. If we start with a lower return water temperature at design, we gain higher efficiency and lower operating costs year round, and as we reset during warmer weather, the energy costs are that much lower than we could obtain with traditional designs.

What we suggest, is to look at terminal unit selections, with the goal of providing a lower supply temperature and a greater delta T. The key difference to keep in mind is your goal of designing a condensing heating system to match the condensing boilers instead of trying to fit a condensing boiler into a traditional, older system design.

Let’s look at an example. Assume you have a heating system design and there are several types of terminal units. Our example will be a system with three million BTUH and include 50% load in air handing units (AHU), 30% in VAV coils, and the balance in convector/fin tube systems. What can we do to maximize the efficiency of the system?

Air Handling Unit Coil Selection

The AHU system totals 1,500,000 BTUH or 1.5 MBH load. Ask the AHU manufacturer representative to look at selections changing the hydronic end. A traditional 20°F ΔT system would result in:

1,500,000 BTUH = 150 GPM X (180°F – 160°F) X 500

If we change our thinking and lower the supply temperature to the AHU, while raising the ΔT, the result could be:

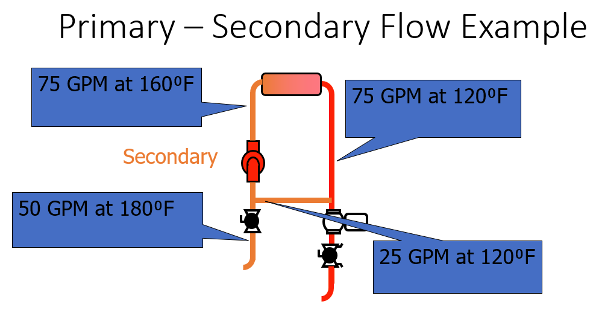

1,500,000 BTUH = 75 GPM X (160°F – 120°F) X 500

The flow rate is less, so the pump horsepower will be less, the pipe size is smaller, and the return water temperature allows the boilers to condense at design. There is a cost increase in the AHU. The coil would have to change but that is a small portion of the total cost. The AHU cost is not affected very much with this change. If the higher 180°F is required from the boilers for other terminal units such as the reheat system, you can use a primary secondary piping system at the AHU coil.

Fin Tube Radiation and Convector Selection

The example system has 20% of the load in baseboard, unit heaters, and convectors. The 600,000 BTUH load could use a larger delta T and smaller flow rate. The fin tube tables are normally designed for a 3 FPS velocity. Assume the “normal” selection would be based on 180°F -160°F. If we change the ΔT to 60 and use 180°F supply a 120°F return, the velocity will drop to 1 FPS at design. The average temperature would drop from 170°F to 150°F. What effect would this have on heat transfer surface?

Using the published data of a popular brand of fin tube, the drop in velocity and the drop in average temperature will influence the amount of finned product needed. It would require us go from single tier to double tier.

Reheat Coil Selection

The reheat system has a distinct set of issues. The flow rates are normally low and we want to keep the supply at 180°F. We would change from a 20°F ΔT to a 40°F ΔT and would not get any more aggressive for this specific application. The flow rates will be too low to balance if we get a larger ΔT.

Boiler System Results

What will the owner experience in costs because of our design changes to the heating system? When you specify Aerco, NTI, and Thermal Solutions condensing boilers, your client is investing in a product which will provide significant energy savings.

What will the owner gain from this change in design? The pumps will be smaller, the pipe will drop from 4” to 2-1/2”. The control valves and terminal piping will be smaller. The AHU and fin tube will cost more but the installation price will be the same. The operational cost of the boiler system with pumps will save $4,500.00 per year. This assumes a Bell & Gossett part load efficiency valve profile and $1.20 per therm gas cost with no temperature reset.

There is more money to gain for the client when we look at the reset schedule with this modern design. That will be the subject of the next R. L. Deppmann Monday Morning Minutes.

Just joining the conversation today? Click below to view the other articles in this four-part series:

Part One: What is the Efficiency of my Installed Condensing Boiler?