Possibly only engineers, like myself, can appreciate controversy in plumbing system design. The use and sizing of storage tanks in variable speed pressure boosters is a current topic at many ASPE (American Society of Plumbing Engineers) and ASHRAE (American Society of Heating Refrigeration and Air Conditioning Engineers) meetings. This short series of R. L. Deppmann MONDAY MORNING MINUTES will address this topic.

A new phrase in business is “Level Set”. It is appropriate since it comes from the construction industry but in business lingo today, it simply means to get everyone on the same page. To that end, let’s start with a brief history of the pressure booster in plumbing systems to get everyone level set.

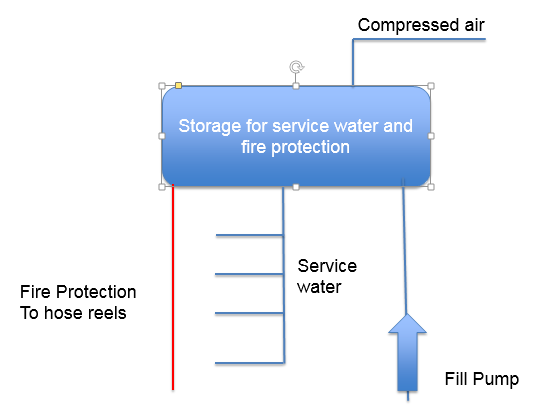

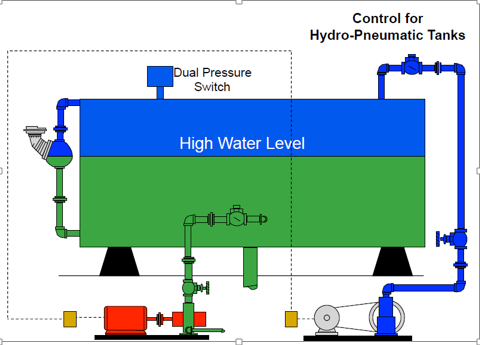

History part 1: When I started in this business over forty years ago there were many buildings in Detroit and Cleveland with large storage tanks in the penthouse or on the roof. These systems stored water in a tank for plumbing and fire protection. Some were open tanks elevated on legs to provide head pressure while others used an air compressor to add pressure. A pump in the basement turned on and off based on a float in the tank. The pump’s purpose was to fill the tank, not pressurize the system. A hybrid of this system is still used today in some ultra-high rise buildings in large cities. See figure 1 &2.

|

|

| Figure 1 – Early 20th-century pressure system | Figure 2– The system (from James M. Pleasants Co. N.C.) |

When the water level dropped in the tank, the float turned the pump on until the level switch was satisfied. A pressure control switch turned the air compressor on and off to pressurize the system. The total tank volume was sized based on plumbing and fire protection needs. The pump flow rate was sized for a minimum flow rate to the satisfy tank volume between the floats in 10 minutes. This assured no more than 6 pump starts per hour to protect the motor and keep the starter contacts from arcing.

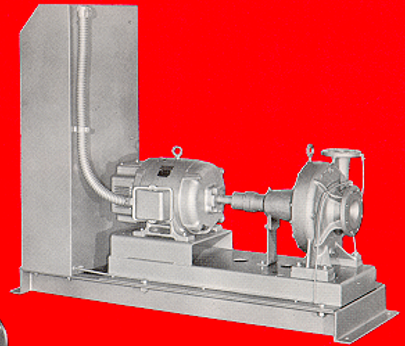

History part 2: In the 1950s there was a new kid on the block of pressure boosters for high rise. The packaged pressure booster located in the basement now pressurized and pumped the entire system. Bell and Gossett provided a variable speed fluid drive pumping system called a Gyrol pumping system. This system had a transmission with chains and an oil reservoir with coolers. The transmission shifted to maintain pressure as load and suction pressure changed. I saw one of these when I first started in the early 1970s. It was in the basement of the Detroit headquarters of the General Motors Building and still operating.

In the 1960s, Bell and Gossett introduced the 70V constant pressure variable speed pressure booster. This used a standard pump and motor with electrodes, electrolytes, and rheostats.

In the late 1960s and early 1970s, B&G again provided the cutting edge, introducing the 70M constant speed booster system to reduce the maintenance costs of previous models. This system used a standard constant speed motor and pressure regulating valves on the discharge of each pump. The system was selected based on the minimum suction pressure expected and the PRVs throttled to maintain a constant pressure by “eating up” any pressure from the city over the minimum design. These systems were normally recommended in 3-pump arrangements with a small jockey pump. This small lead pump ran continuously 24/7 and the larger pumps came on when demand increased. There are many of these systems still in use today.

|

|

|

| Bell and Gossett Gyrol Variable speed pressure booster | Bell and Gossett 70V variable speed pressure booster | Bell and Gossett 70M constant speed pressure booster |

In the 1980s with rising fuel and utility prices, office building owners looked at these constant speed booster systems and wanted to turn that jockey pump off at night. The problem was that the pump did not stay off long and often cycled continuously if there were any leaks in the building. What 8 story office building in a downtown area did not have leaks!

The solution was to bring back a tank into the system. It could be similar to the tanks of old but engineers turned to a newer technology, the pre-pressurized bladder tank.

In our next issue of Monday Morning Minutes, we look at the sizing of tanks for constant speed booster systems and discuss some basics needed for variable speed system tanks.