The piping at the suction side of the pump is the most important and, for some engineers and designers, the most misunderstood part of hydronic pump piping and trim. The spoken rule of thumb is five pipe diameters of straight pipe into the suction of the pump. Although this is spoken often, it is rarely seen in a mechanical equipment room. There are hundreds of thousands of pumps installed without five pipe diameters in front of the suction. What does the engineer do?

The piping at the suction side of the pump is the most important and, for some engineers and designers, the most misunderstood part of hydronic pump piping and trim. The spoken rule of thumb is five pipe diameters of straight pipe into the suction of the pump. Although this is spoken often, it is rarely seen in a mechanical equipment room. There are hundreds of thousands of pumps installed without five pipe diameters in front of the suction. What does the engineer do?

I’ve often said, “In general, hydronic heating and cooling pumps have a pretty easy duty.” They are not pumping paper pulp with bailing wire pieces. Pumps in hydronic systems pump clear liquid at reasonable pressure and temperatures, most times with plenty of suction pressure.

Open and Closed Systems

Our closed hydronic systems have a lot of suction pressure caused by the combination of the fill pressure and expansion tank maximum pressure. Open cooling tower systems or open systems lifting from a lake or pond have a completely different set of rules. It is critical to follow the manufacturer’s instructions in these applications. Today we will focus on closed systems.

The Hydraulic Institute (HI) and Closed System Pump Piping

The Hydraulic Institute (HI) has a number of standards for suction piping to a centrifugal pump. In closed systems, the suction piping velocity should be limited to 8 feet per second (FPS) at design (HI 9.6.6.3.1). A few weeks ago we suggested a maximum of 10 FPS on the discharge of a hydronic pump because of the limitations of the check valve. So if the engineer designs the pump suction and discharge piping for a maximum of 8 FPS, both limitations are met.

The suction piping should be at least as large as the pump suction connection (HI 9.6.6.3.1). This seems simple but we have seen some installations where the suction of the pump was choked down.

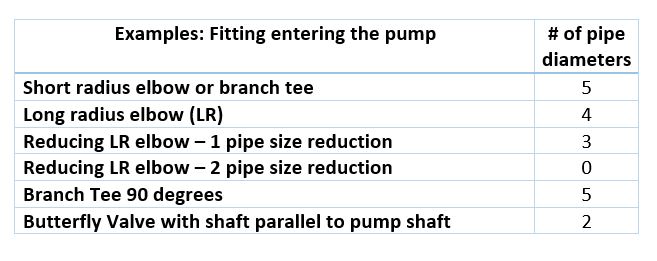

What about the pipe section right at the pump? The most disturbing flow pattern into the pump is a “piping generated swirl”. Swirling occurs as the water flows through a fitting causing the water in the pipe to change all or part of its direction. Generally, in hydronic installations this fitting is an elbow. B&G suggests 5 pipe diameters or the use of a suction diffuser. Interestingly enough, a reducing elbow requires less straight pipe then a straight elbow. Let’s look at a few examples from HI.

So why does a reducing elbow require less diameters than a straight elbow? As the area is reduced into the suction of the pump, the swirling is reduced. This list above is not exhaustive. There are many more situations in the HI table of fittings.

Single Suction vs Double Suction Piping

What does R. L. Deppmann think about this piping? We don’t see 5 pipe diameters in front of horizontal split case pumps very often, yet there are a lot of very old split case pumps out there!

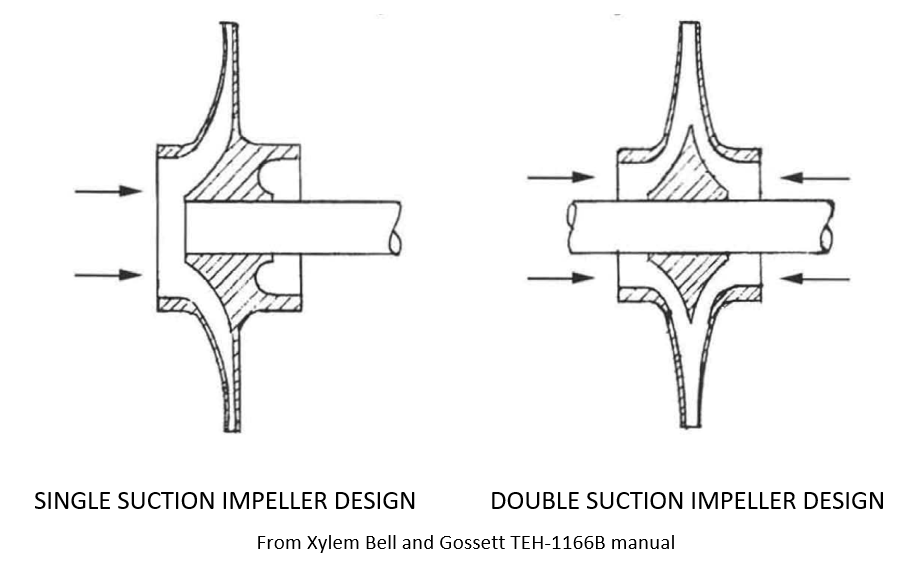

Single suction pumps such as the B&G e1510 end suction pump or the e80SC vertical inline pump have water entering a single hole or eye of the impeller. Any swirling in this application will cause a pressure imbalance from one side of the impeller to the other. Although not perceptible to our eye, this imbalance will end up causing more repair and downtime than if it did not exist. In a double suction pump, the water enters the pump and then goes through two sides of the impeller. The water is changing directions in the pump and then entering the impeller on both sides. In our opinion, this tends to reduce swirl and balance the flow in the impeller.

So many hydronic details show a suction diffuser on the single suction pumps and a strainer, elbow, and reducer on the double suction pumps. This does not meet the HI letter of the law, but it is what our industry shows in details.

When you are using a “high energy” pump, the suction piping becomes more critical. Pumps with a larger horsepower will tend to be categorized as higher energy. I’ll cover energy in another article. Meanwhile, we can make the following recommendations for pumps under 100 HP. We recommend details show the suction diffuser or, as an alternative, a strainer and a long radius reducing elbow with support on single suction base mounted or floor mounted inline pumps. We recommend double suction horizontal inlet pumps use the suction diffuser or strainer, or a long radius elbow with support and a reducer for double suction pumps.

These recommendations are for B&G pumps and are based on our 90 years of experience here at R. L. Deppmann. I’ll let other pump suppliers comment on their own requirements.

We will discuss more on this subject in next week’s R. L. Deppmann Monday Morning Minutes.