Mechanical rooms seem to get tighter every year. The engineer begs for space, but in the end, the mechanical room piping is very tight. Now you specify several magnetic flow meters only to be confronted with required pipe diameters before and after your meter. Here is a great solution just introduced from Badger Meter.

Traditional Installation Requirements

Traditional hydronic and plumbing flow meters with BMS capability have restrictions on the location in the piping system as well as the types of fittings and valves in front of them. The very forgiving inline mag meter has traditionally required enough pipe diameters to be a challenge at times. This is the required amount of straight pipe before and after the device to ensure accuracy.

Badger meter listened to engineer and contractor concerns and re-tested the popular M2000 mag flow meter series. Badger tested the meter with tighter and tighter installations. They proudly announced the ModMAG M2000 maintains at least 1% accuracy with zero pipe diameters when installed in front of an elbow. Of course, with more pipe diameters, the meter will remain ¼% accurate. Usually, that level of accuracy is rarely needed in HVAC control applications.

The R. L. Deppmann Monday Morning Minutes Flow Meter and Balance Valve Installation – Minimum Pipe Diameters for Installation (deppmann.com) has been revised with this important change.

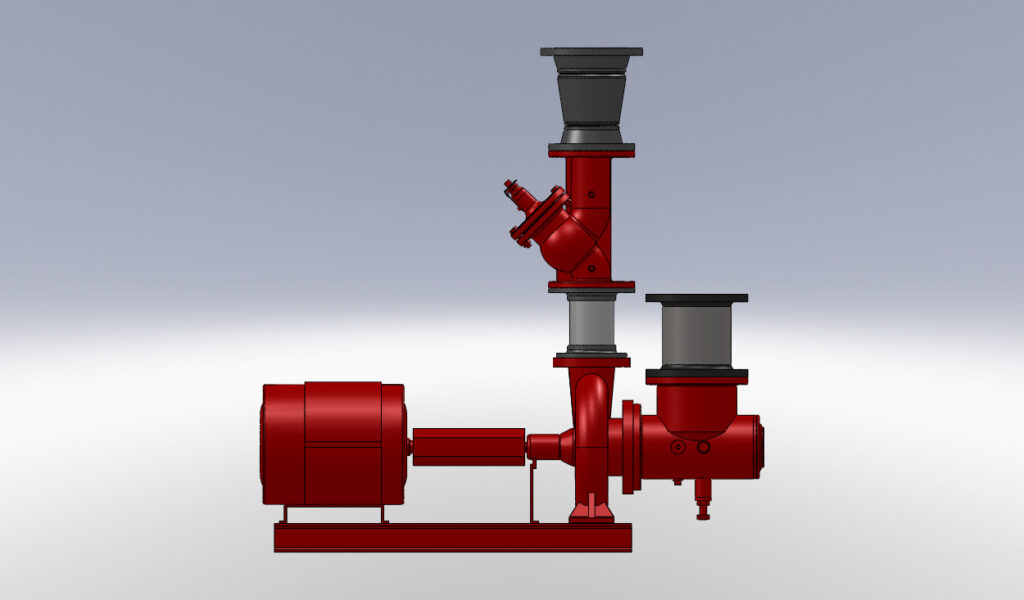

Pump or Chiller Installations

We continue to stress that flow meters should NEVER be installed after a check valve or pump. The pump discharge is the most turbulent area in the entire hydronic system created by both the pump and check valve.

I come with great news. The water flow rate leaving the discharge of a pump is the same as the flow rate coming into the pump. Yes, I am grinning as I key that in! My point is, why not install a Badger M2000 in the return line coming down from the header to the pump suction or chiller?

When the meter only needs a couple of diameters of straight pipe upstream and one downstream, there is usually room between the shutoff and the strainer to mount the right flow meter. Even a 12” meter would only require a few feet.

Of course, unless the flow of each pump or chiller is important, the mag meter should still be in the return header to all pumps. The M2000 has enough turndown to handle the wide range of flow rates in a typical system.

Want More Information?

Visit Badger meter at ModMAG | M2000 Electromagnetic Flow Meter | Badger Meter for more information or contact us with this link.