We are continuing with the series on Condensing Heating System Efficiency. Today, we are discussing condensing boiler temperature reset for increased efficiency. Hydronic condensing heating systems are designed to take advantage of the condensing boiler investment on a design day. We know that the cold design conditions happen a minimal number of hours per year. We can enjoy great efficiency during the rest of the year by incorporating a deep outdoor reset schedule. This R. L. Deppmann Monday Morning Minutes explores reset strategies.

What is Temperature Reset?

The design conditions of a boiler system are, in large part, based on outdoor weather condition. The outdoor design point can range from -12 degrees F in the Upper Peninsula of Michigan to +2 for Findlay Ohio. The heat loss of your building is the greatest when the outdoor temperature is at your area’s outdoor design temperature. Your boiler plant is usually designed to deliver the maximum temperature, for example 180 degrees, at this condition.

Sizing the heating plant for the outdoor design condition will keep your building warm for those few coldest days. The rest of the year, less load is needed. In effect, the rest of the year the boiler plant is oversized since you need less heat (BTUs) to stay warm. If the terminal devices in your system are supplied with a lower supply temperature, giving a lower average temperature, they will put out lower BTUs.

This lowering of the heating supply water as the outdoor temperature increases is called Outdoor Reset. This is one method of matching the heat generated to the heat loss of the building.

Temperature Reset is Not New

Using outdoor reset in buildings is nothing new. Reset was applied for smoother building temperature control. For many years it was accomplished using a three-way mixing valve in constant flow systems with large fire tube or bent tube boilers which required no minimum flow rate.

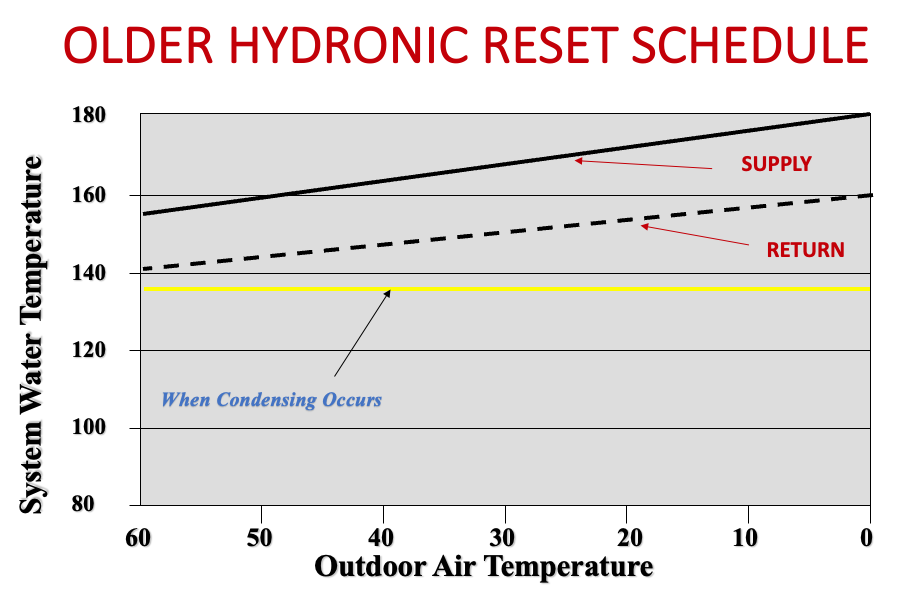

In the years past the lowest reset temperature of a boiler was often 160° supply water. With a 20° ΔT across the system, the return water would be 140° minimum. In non-condensing (older) boilers this is about the lowest allowed return temperature to keep them from condensing. If you condense in a non-condensing boiler the life of the unit will be severely shortened due to the destructive acidic nature of flue gas condensate. Advanced controls made sure the return temperature never dropped to the point of condensing.

By using today’s condensing boiler technology with heat exchangers designed for the acidic condensate, your building would use a deep reset schedule that allows the return temperature to cause condensing of the flue gases.

Condensing Boiler Efficiency & Return Water Temperature

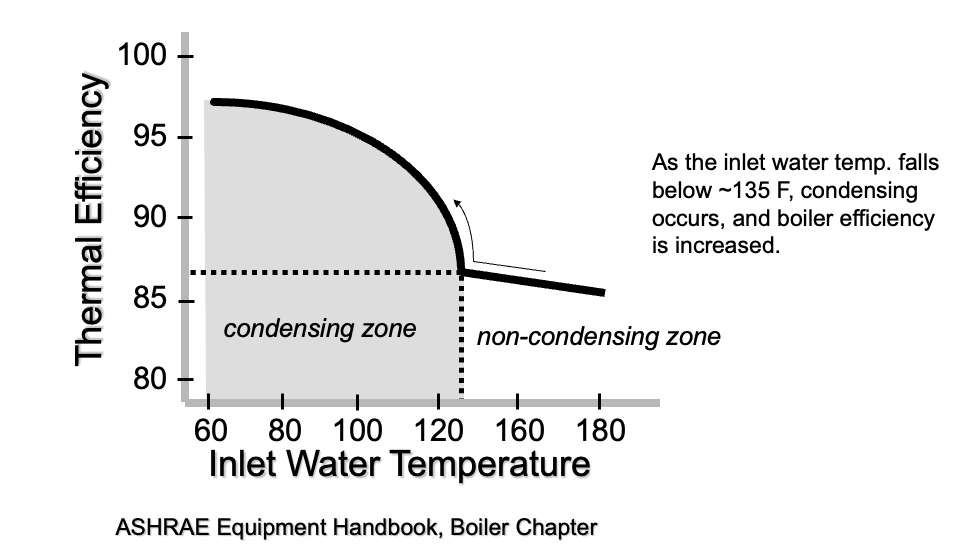

Part 1 of this series, “What is the Efficiency of my Installed Condensing Boiler?” described the value of lower return water in condensing boilers. If our system uses the older traditional 20⁰ ΔT but adds a deep reset schedule, look what happens.

The boiler plant will begin condensing at about 26⁰ outdoor air temperature. This really starts to pay for the condensing boiler investment.

The boiler plant will begin condensing at about 26⁰ outdoor air temperature. This really starts to pay for the condensing boiler investment.

Condensing Boiler Efficiency & Larger ΔT Design

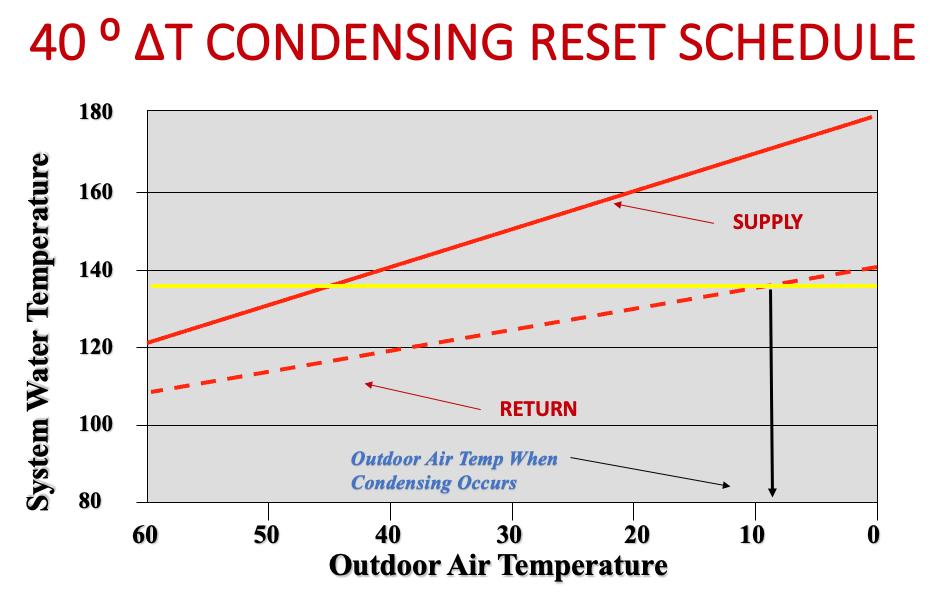

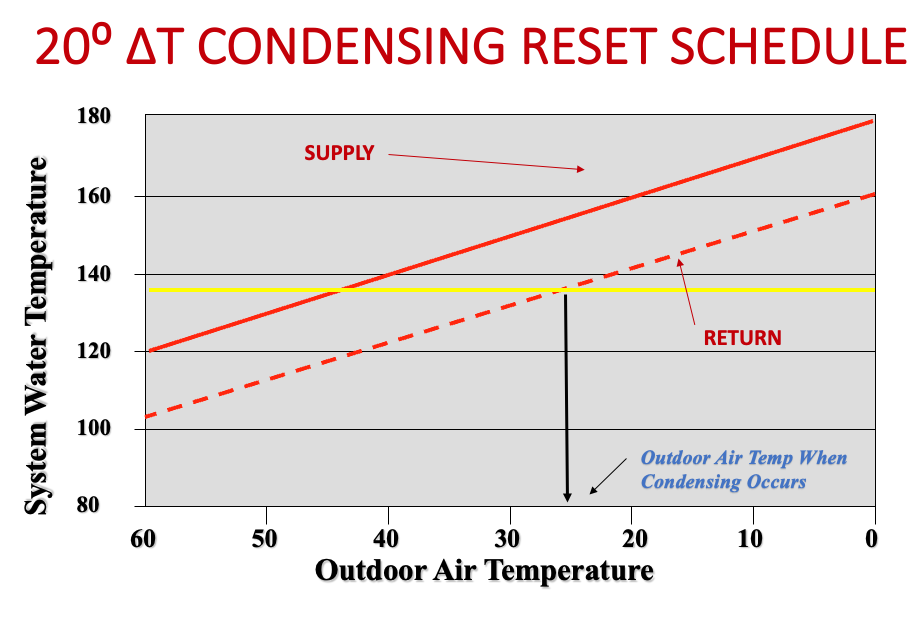

In part 2 of this series, “Hydronic System Design: High Delta T Can Improve Boiler Efficiency”, we increased the temperature differential of the system significantly. When we apply the deep temperature reset schedule, things get interesting.

Now our condensing hydronic heating system design will begin producing payback when the temperature outside is above 9°. If we used the example from part 2, we could be condensing all the season.

Obviously, the hydronic system design temperatures must work with the terminal units selected. The key point is to attempt to design so the return temperature is as low as feasible and then add a deep reset schedule. These two thoughts will save your client some green. These two points also save energy, and we all know that is green.

Next week we will conclude the series by adding the last two concepts: dual returns and staging of multiple boilers.

See the rest of this series here:

What is the Efficiency of my Installed Condensing Boiler? (Part 1 of 4)

Hydronic System Design – High Delta T Can Improve Boiler Efficiency (Part 2 of 4)