This is part one of a four article series on Condensing Heating System Efficiency. Each week we will discuss maximizing efficiency not through product selection, but rather through smart system design.

Let’s begin with a question: what is the efficiency of your installed condensing boiler? If you answered 97% like most people, you are not alone. You are most likely not correct, but you’re also not alone.

Boiler Thermal Efficiency

Most boiler manufacturers have jumped into the world of condensing boilers, and they are using the power of effective marketing to help differentiate them from the competition. While condensing boilers can be tested to reach 97% efficiency, the return temperature required would render the boiler useless in most systems. Running the boiler at a return temperature that is so low, means that in most systems, it would not be able to effectively heat the desired space and would require a massive amount of heat transfer surface in order to achieve the occupants’ desired room temperature.

Given these limitations on the efficiency of a single boiler, we should instead think of maximizing efficiency not through product selection, but rather through smart system design. In this article, we will introduce ways that you can maximize boiler thermal efficiency with a high-quality boiler such as the Aerco BMK3000 Benchmark Boiler.

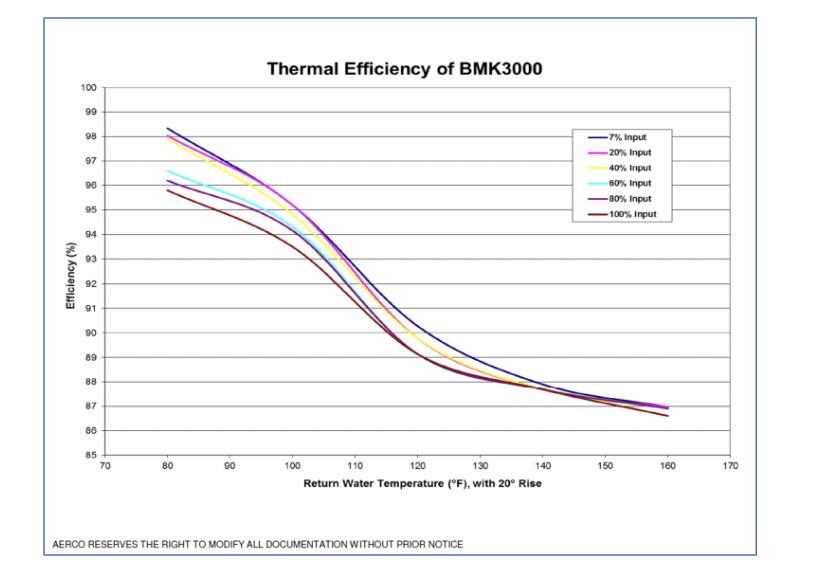

Using the above efficiency chart for the Aerco BMK3000 Benchmark Boiler, one can see that a hydronic system with a temperature range of 180°F – 160°F system will not get you to that level of efficiency. In fact, the system requires a 90°F return water temperature AND the burner will have to be modulated down to below 50% to achieve the highest efficiency. At full fire and a return temperature of 160°F, this boiler will operate at about 86.5%.

Improving Condensing Boiler System Efficiency by Design

The engineer has the power to improve the operating efficiency of the boiler system with a few, well-placed design decisions:

- Expand the terminal temperature differential to 40- or 50-degrees delta T. The boiler thermal efficiency depends on the return water temperature. If we look at the graph above, the full-load efficiency will rise from 86.5% to 89% by changing the return temperature from 160°F to 120°F. This will affect the terminal unit sizing but the reward in operating cost is huge.

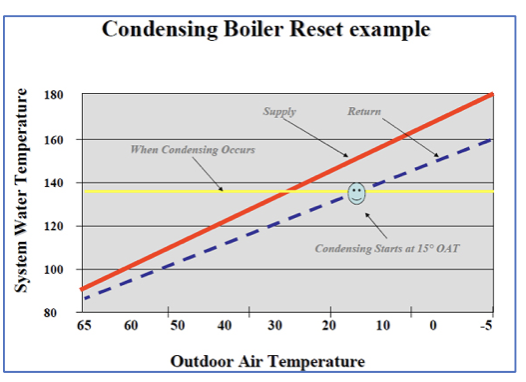

- Use a deep temperature reset schedule. Resetting the supply water temperature to coincide with the outdoor temperature is a terrific way to improve the condensing boiler efficiency.

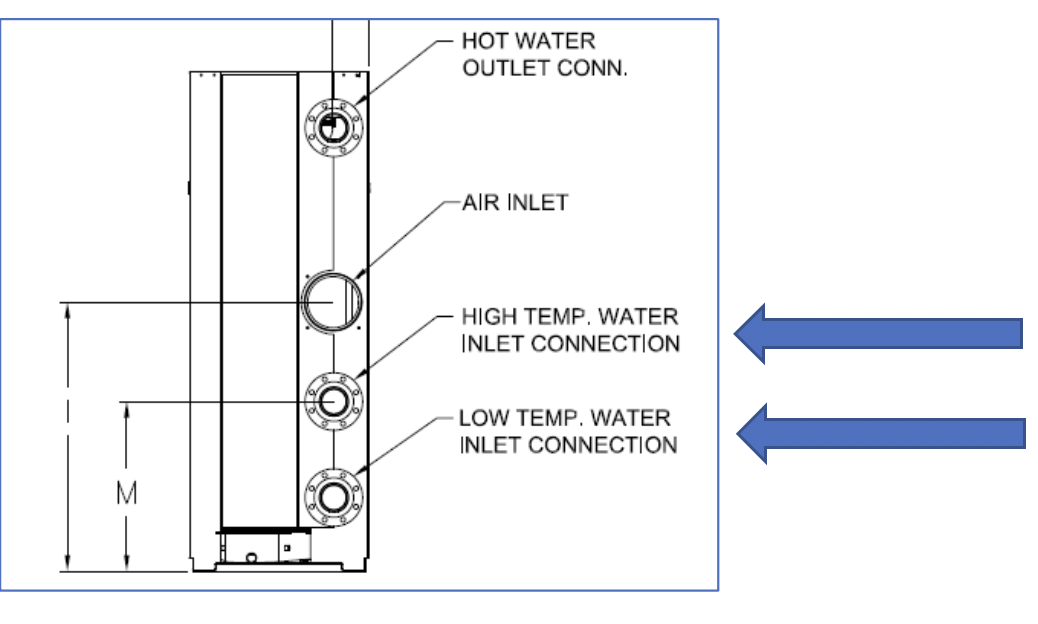

- Use dual return boilers when appropriate. A deep reset schedule is not always possible. You may have terminal units which require higher supply temperatures even when the outdoor temperature is moderate.

- Stage multiple boilers at lower firing rates. Operating a single boiler and “topping it off” with a cycling second boiler is a thing of the past. Condensing boilers are more efficient at lower firing rates. It is better to operate three boilers at 30% each than a single boiler at 90%. This assumes the boiler you specified has a large turndown ratio to prevent cycling at the 30% point. Look, once again, at the Aerco Benchmark curves above with a 3,000,000 BTUH input. If the return temperature is 120°F, at 90% load, this boiler operates at a nice 89% thermal efficiency. If I have a large boiler plant, I can operate three Aerco boilers at 30% each. That will raise the efficiency to 90%. That one percent efficiency will pay for the boiler staging software included with the boiler. The example Aerco BMK3000 boilers have a great turndown capacity. If your boilers cannot turndown too far, you must take cycling losses into account, and you may not get the better efficiency.

We will address each of these points in the next few R. L. Deppmann Monday Morning Minutes.