There are a variety of unfired liquid to liquid and steam to liquid heat exchangers for the engineer to choose from. The Gasketed Plate, Brazed Plate, and the Shell and Tube are the main styles used in building HVAC and plumbing as well as industrial applications. Today’s R. L. Deppmann Monday Morning Minutes will review shell and tube heat exchangers and discuss the different available styles.

There are a variety of unfired liquid to liquid and steam to liquid heat exchangers for the engineer to choose from. The Gasketed Plate, Brazed Plate, and the Shell and Tube are the main styles used in building HVAC and plumbing as well as industrial applications. Today’s R. L. Deppmann Monday Morning Minutes will review shell and tube heat exchangers and discuss the different available styles.

Shell and Tube Style Heat Exchangers

Shell and tube heat exchangers have existed for almost two centuries in one form or another. The shell is a piece of pipe or a tank that contains one fluid. There is a tube or set of tubes placed inside the shell that hold the other fluid. The tubes are held in place by one or two tube sheets. The shell and tube heat exchanger may have a removable tube bundle, or it may be fixed.

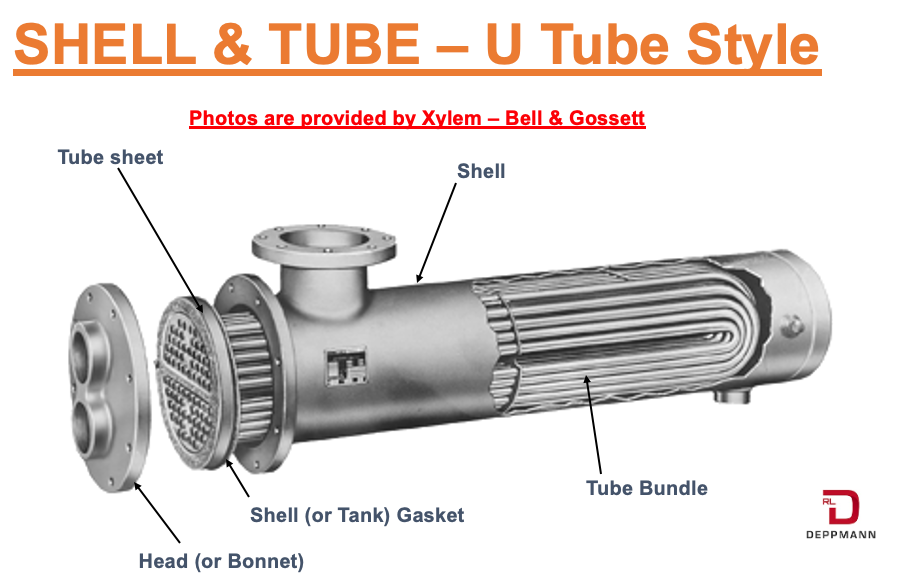

U-Tube Heat Exchanger

The U-tube style is the commonly used heat exchanger in institutional HVAC heating systems. A representative cut-away of the Bell & Gossett SU series heat exchanger is shown above. This model has tubes available in various materials. Each tube is attached to a hole in the tube sheet. The attachment is normally a serrated press fit but could also be attached by another method. These tubes are bent halfway down and returned to another hole in the tube sheet. The tube is in the shape of a “U.” The “U” is close to the end of the shell but there is a space between the tube bundle and the end of the shell.

A clear advantage of these models is the ability for the tubes to expand since the end of the tube bundle is free to move. This is a particularly great advantage when one of the fluids is steam and the other a water or glycol mixture. When copper or stainless is heated, it will expand. You cannot stop mother nature. Example: A heat exchanger is installed when it is 50⁰F and the steam temperature will be 250⁰F (15 PSIG). The steel shell will grow 1.5 inches as the temperature increases. The copper tubes will grow 2.3 inches. The extra 0.8” must go somewhere. The “U portion will grow and expand into the shell since the tubes are locked into the tube sheet on one side. Visit our Monday morning minute Hydronic Expansion Joints (Part 1) | R. L. Deppmann for more on this topic.

We would normally put the hot fluid in the shell and the colder fluid in the tubes. This provides the best heat transfer. In a horizontal installation, the shell normally has the steam in the top and condensate out the bottom. The U-tube has also been used for liquid to liquid applications.

Straight Tube Heat Exchanger

The straight tube style of shell and tube heat exchanger is used in a variety of industrial liquid to liquid applications. Many of the applications for this style of exchanger tend to be replaced by plate style heat exchangers. There are still applications when these are used.

Fluids with dirt and particulate may find the larger tubes of the straight tube design a good fit compared to plate heat exchangers. There is no bend in the tubes. There is a tube sheet on both ends of the exchanger. The two heads can be removed, and the unit can be cleaned using rods and pushing straight through each tube. This becomes even easier if the specification calls for a channel head which is shown below.

The channel head now allows cleaning without disturbing the piping connections. The plate on the channel head is removed exposing the tubes for inspection and cleaning.

Most of these models have fixed tube sheets on both ends. There would be little ability to manage expansion and contraction as the “U” tube models can. The temperature difference from the hottest to coldest fluid is normally limited to 100⁰F.

These units were used with fluids with close temperatures. Because the liquids are only flowing in one direction, they can be piped in counterflow.

Counterflow simply means that the two fluids are always moving in opposite directions. This made them highly effective for heat recovery applications. I use the past tense because the newer plate style heat exchangers can also be piped in counterflow and use less room. The plate style heat exchangers will be the subject of the next R. L. Deppmann Monday Morning Minutes.