You have a Bell & Gossett Flo-Control valve on the primary secondary bridge of an older hydronic system. It has been there for over five decades but is making some noise and needs to be replaced. Why is it there? Do I need it? What do I do if the replacement is not in stock or immediately available?

You have a Bell & Gossett Flo-Control valve on the primary secondary bridge of an older hydronic system. It has been there for over five decades but is making some noise and needs to be replaced. Why is it there? Do I need it? What do I do if the replacement is not in stock or immediately available?

A B&G stocking wholesaler recently called our senior customer service consultant, Scott Tilley, with a hydronic repair issue. They had an old Bell & Gossett model S-3 Flo-Control valve on the bridge of a primary secondary hydronic heating system. The valve had failed after 60 years, and the contractor needed to replace it. The weather was very cold in Michigan and the product was not in the R. L. Deppmann stock. The factory lead time for this cast iron product was a couple of weeks. The owner could not wait.

The interesting thing was the wholesaler, and the service contractor were young enough that they had never heard of this product let alone seen one. Here is how Scott answered them.

What is a B&G Flo-Control Valve and Why Does It Exist?

A Bell & Gossett Flo-Control valve is a gravity check valve with a manual bypass. Its purpose is to prevent gravity circulation of hot water from the supply mains into the secondary loop on the return side.

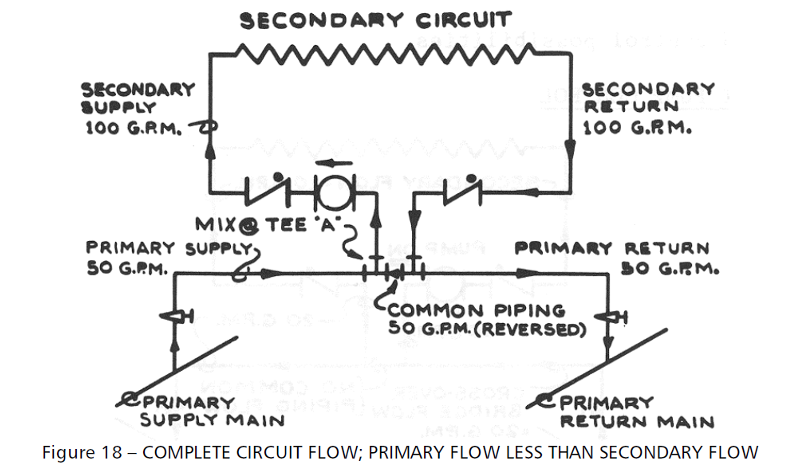

Look at figure 18, shown above, from the Bell & Gossett TEH-775A Primary Secondary (P-S) Pumping Application manual available under Tools to Select and Design HVAC & Plumbing Equipment | R.L. Deppmann. Notice the check valve on the discharge of the pump. That is common practice. If you look at the secondary system return piping, you will see what appears to be a second check valve. It is not there as a backup check valve.

The device on the return is a B&G Flo-Control check valve. Notice the piping of the return to the secondary is on the top of the crossover bridge piping. When the pump is off there should be no flow of water into the terminal unit and therefore no heat. But hot water rises and cold water falls. It is possible to get gravity circulation from the crossover bridge to the secondary terminal unit. The B&G gravity check Flo-Control valve prevents this from happening. It had a heavy weighted check and will take about 1/3 PSIG or about 0.8 feet to lift the check valve. That is why the submittal curve starts with a pressure at 0 GPM. It takes some pressure to lift the heavy cast iron weight.

If you want to read about why there weight is the size it is, then visit our previous Monday Morning Minutes article, Hydronic System Primary-Secondary Rules-Decoupling Systems.

Do I Still Need the Flo-Control Valve?

One of the first questions a service contractor will ask is whether the component is even needed. There is a chance that it is not needed. If you look at the system P-S piping above, you will notice there is no temperature control valve on the terminal unit. Way back when a color TV was a luxury, so were control valves. Many primary secondary circuits were designed to cycle the pump on and off to maintain temperature. You may laugh but if you think for a moment, that is how most furnaces work today; On-Off control.

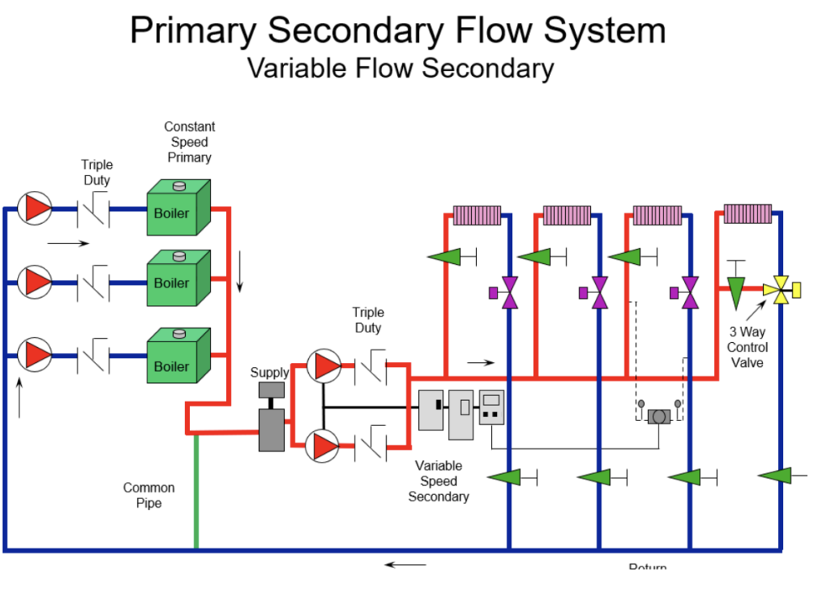

Look at the heating system shown above. It is a P-S piping system but there is no Flo-Control shown on the return. The reason is that there is a control valve on every terminal unit. If there is no need for heat, the control valves will be closed, and flow will stop.

What Can We Use Instead of the Flo-Control?

Let us assume the valve was still needed. The delivery time is too long. If you look at the photo at the start of this article, there is a nut on the top. That is to provide access to the parts without removing the valve from the pipe. Scott asked about parts but, in this case, the valve body had been damaged and so the whole thing had to be replaced.

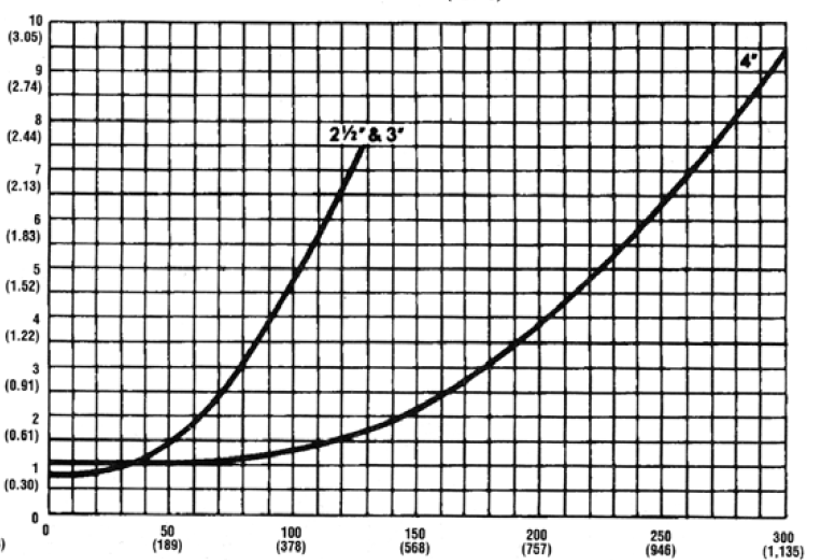

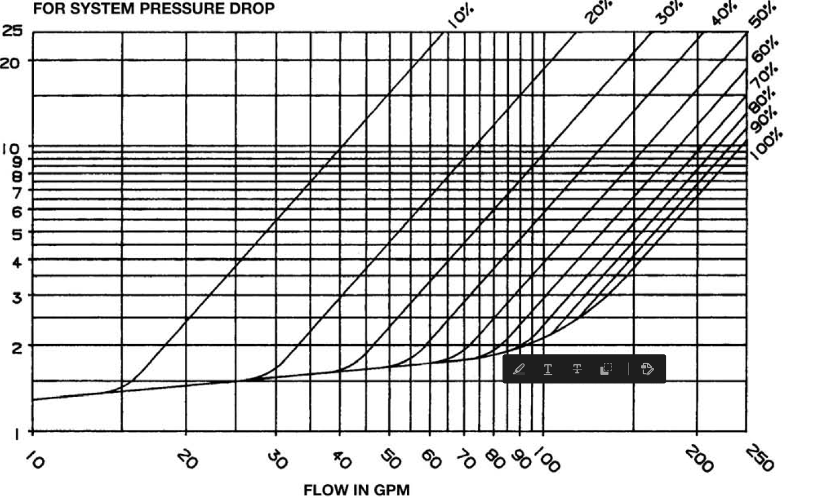

The purpose is to stop gravity circulation by causing about ½ PSIG to lift the check. That is how many spring loaded check valves work. B&G suggested using a straight pattern triple duty valve with a curve that looks like this.

Notice that the curve, taken from the B&G triple duty curve booklet starts at about 1.3 feet. This is due to the spring-loaded check valve. The only problem was the face-to-face dimensions which were longer than the Flo-Control.

Another possibility was a Metraflex Globe style check valve.

This valve had a low pressure drop to open and a smaller face to face than the Flo-Control. It is not an exact match but was close enough ton get heat back into the building. Our Scott Tilley gave the wholesaler enough information so the service contractor could make a better decision and that is what R. L. Deppmann is all about.