How many times have you, as an engineer, looked at a number of curves and passed up a few because you did not like something about the selection on that curve? In the last R. L. Deppmann Monday Morning Minute we looked at end of curve selections. Today we examine constant speed pump selections near the top of the curve.

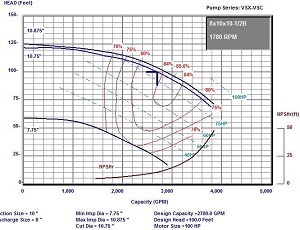

Limiting top of curve on constant speed selections. Figure 1 is one possible selection for a capacity of 2700 GPM at 100 foot head. This selection is at only 71% of the end of curve point and is 84.5% efficient. It is a great selection EXCEPT you pass it up because it is “too close to the top of the curve”. When working with consulting engineers, I hear this a few times a year. The concern is the inability to change the impeller and gain a little pump head if the calculations were off or an alternate terminal unit is selected with more pressure drop.

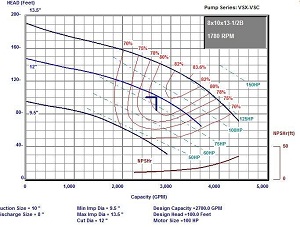

This next selection has more room to the top of the curve and has the same suction and discharge sizes. It is a little less efficient but remains non-overloading at 100 HP.How do you let the bidders know you want this selections and not the selection above? If we are scheduled, Deppmann will most likely bid the pump you scheduled. Competition may bid the smaller pump above because it is 30% less expensive than

This next selection has more room to the top of the curve and has the same suction and discharge sizes. It is a little less efficient but remains non-overloading at 100 HP.How do you let the bidders know you want this selections and not the selection above? If we are scheduled, Deppmann will most likely bid the pump you scheduled. Competition may bid the smaller pump above because it is 30% less expensive than

the one you selected.

SOLUTION: The first pump is more efficient and less expensive. Someone is going to try to use it unless you specify that you passed it up. How do you do that? There are two ways to handle this. Specify a fixed maximum percentage of the published curve or specify a required increase in pump head in the selected pump.

The first solution would read, “Unless noted on the pump schedule the selected impeller diameter for constant speed pumps must not be greater than 90% of the maximum impeller diameter.” The selection above meets this criterion. The problem with this specification is you may often make selections that do not meet your own spec! If the required capacity was 2700 GPM at 120 feet you may still like the selection above but it does not meet the 90% max diameter section in your specification.

The second solution would read, “Unless noted on thepump schedule the selected impeller diameter for constant speed pumps must be chosen to allow a future impeller change to provide a capacity of 110% of the scheduled flow rate at 110% of the scheduled head.” Now, you have specified a point which allows the room you want and is easy for you to check when making your selections.

This discussion is all about constant speed pumps. For variable speed pumps, there are other considerations. Visit our Monday Morning Minute on Variable Speed Hydronic Pump Selection here.

Disclaimer: R. L. Deppmann and its affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.