In the last R. L. Deppmann Monday Morning Minutes, we suggested a specification that would allow a future impeller change as a means of adding some safety factor to the centrifugal pump provided on your project. What happens if you want to select a pump with a present and future condition?

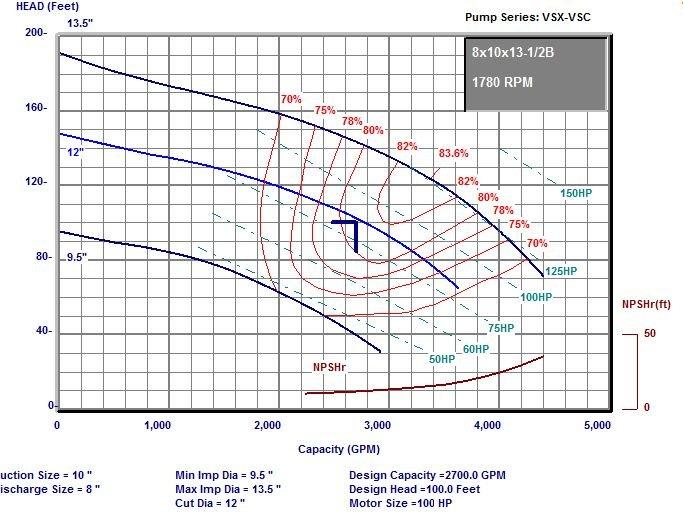

Here is a good pump selection for a capacity of 2700 GPM at 100 foot head using a 100 HP 1750 RPM motor. Let’s assume you want to be able to increase the capacity to 3000 GPM at 130 foot head in the future.There are two possible solutions using this pump. 1. Install this pump now with a 100 HP motor and 12” impeller and change the motor and impeller in the future. 2. Install the pump now with a 13.5” impeller and 125 HP motor and use a variable speed drive to reduce the maximum speed for the current condition.

Option number one would be advantageous if you are not running the current pump on a variable speed drive or if the future condition will not occur for a long time or may never occur. One thing many engineers are not aware of is that although the pump curve in our example can handle up to 150 HP, the change from 100 HP to 150 HP may require a different base, coupler & accessories. A new base requires the pump be removed and involves piping modifications!

If you expect to increase the pump capacity in the future, I would recommend a note on the schedule identifying future capacities and the requirement for the pump to be able to handle the change without removal of the pump. Your note could read; “This pump will have a future requirement of 3000 GPM at 130 foot head with a future 150 HP motor. The pump must be supplied with the proper base and trim so the future condition can be met without removing the pump from the piping connections”.

The second option makes sense if you know the future capacity will occur in a short time frame or if the current pump is operating with a variable speed drive. In this case, schedule the future conditions and larger horsepower and use a variable speed drive to “reduce” the impeller in the present condition. The schedule note would read, “Mechanical contractor is responsible to adjust the maximum speed within the drive to meet the current condition of 2700 GPM at 100 feet”

Disclaimer: R. L. Deppmann and its affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.