Centrifugal Pump Selection Maximum Point on the Curve

| How many times have you, as an engineer, looked at a number of curves and passed up a few because you did not like something about the selection point on that curve? In the December 6, 2010 R. L. Deppmann Monday Morning Minutes, we look at how to specify and schedule pumps to limit the bidders to specific pump curve characteristics.

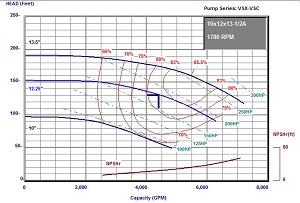

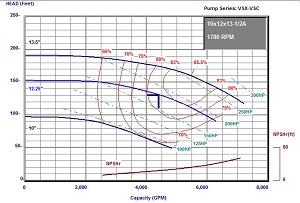

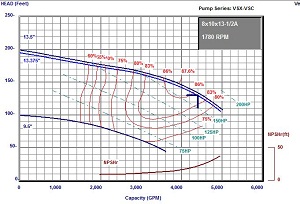

POINT ONE: How close to the end of the curve do you select? Look at Figures 1 & 2 below. Let’s assume you selected the pump in figure 1. You specified the design GPM and Head and 200 HP. You specified the minimum efficiency of 82.15.

|

|

| Figure 1 – click to enlarge |

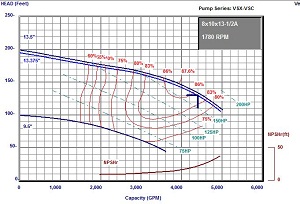

Figure 2 – click to enlarge |

The submittals come in and you receive a submittal similar to the pump in figure 2. What happened?

The pump in figure 2 meets the flow, head, horsepower, and is even 3% better in efficiency but you are not happy. The obvious answer is that in the competitive bidding environment, pump P2 is less expensive.

SOLUTION: The manufacturer of the pump in Figure 2 is willing to guarantee it will operate at the selection point but it is too close to the end of the curve. Maybe you are concerned about drift as control valves open and close. Maybe you are concerned about velocity noise. There are two ways to handle this. Specify a maximum percentage of the published curve. The selection in Figure 1 is 70% of the end of the curve flow and Figure 2 is at 89%. Specify a maximum suction velocity.

SPECIFY: Pump selections shall meet the scheduled capacities and be selected so the scheduled design flow rate is not greater than 85% of the published end of curve flow rate for the impeller selected. Extrapolations beyond the published curve will not be accepted. Unless noted on the schedule, the maximum suction velocity shall be 20 FPS for double suction pumps and 12 FPS for end suction and inline pumps.

For the everyday systems, these criteria will help protect your selection intent during the submittal stages. When you get to larger pumps over 5000 GPM you may elect to increase velocity limitations. As always, we are ready to review our customers’ selections ad offer objective input before the project is out for bids. |

|

Disclaimer: R. L. Deppmann and it’s affiliates can not be held liable for issues caused by use of the information on this page. While the information comes from many years of experience and can be a valuable tool, it may not take into account special circumstances in your system and we therefore can not take responsibility for actions that result from this information. Please feel free to contact us if you do have any questions.

Archives – Click here for Past Articles