An engineer asked a question about using a variable speed pump for air temperature control in lieu of a two-way control valve. What are the advantages of using variable speed coil pumps with no 2-way modulating control? Today, the R. L. Deppmann Monday Morning Minutes gets the thought process going.

An engineer asked a question about using a variable speed pump for air temperature control in lieu of a two-way control valve. What are the advantages of using variable speed coil pumps with no 2-way modulating control? Today, the R. L. Deppmann Monday Morning Minutes gets the thought process going.

Why Consider Leaving Our Comfort Zone of 2-Way Control Valves?

There are engineers out there that live with the adage, “If it ain’t broke, break it and re-engineer it to save energy.” Others may wonder why bother if it works. When we think about hydronic system pumps and control valves, we think about the car with the foot on the accelerator and brake pedal at the same time. We know we are using energy.

Even with variable speed drives, we are using more energy than needed. If one zone needs full heat and others do not, there are throttled control valves. Throttled control valves mean wasted energy. The energy number wasted may not be huge, but it is a significant percentage of the total pumping horsepower.

Looking at the explanation and the numbers will be easier with an example.

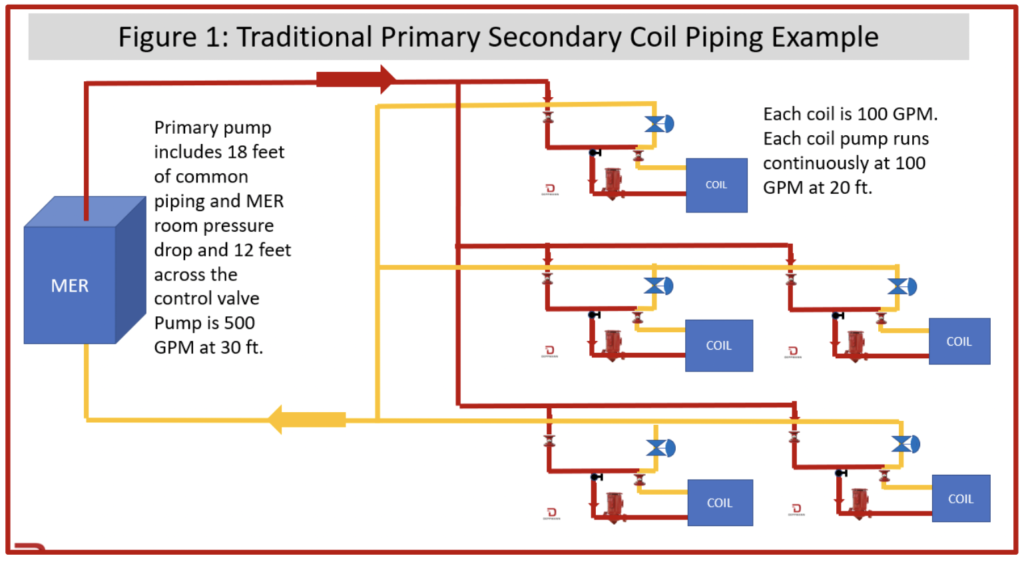

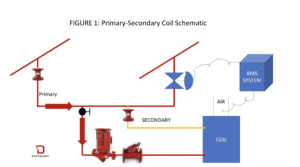

Variable Primary – Constant Secondary System with Two-Way Control Valves

The system above is a traditional primary secondary system with five air handling units (AHU). The primary pump is 500 GPM at 30 feet and is variable speed. The control is monitoring a differential pressure (DP) sensor at the farthest zone and is set for 15 feet which is the two-way control valve, circuit setter, and a few feet of pipe. The control could also monitor the valve position in lieu of DP.

The coil pumps run continuously at a constant flow and the 2-way acts to vary the supply temperature to the coil. The pump energy used is the sum of the five constant flow coil pumps and the variable speed primary pump. Using a load profile of the B&G PLEV model, the annual pump operating cost in Michigan or Ohio is about $2,750.00.

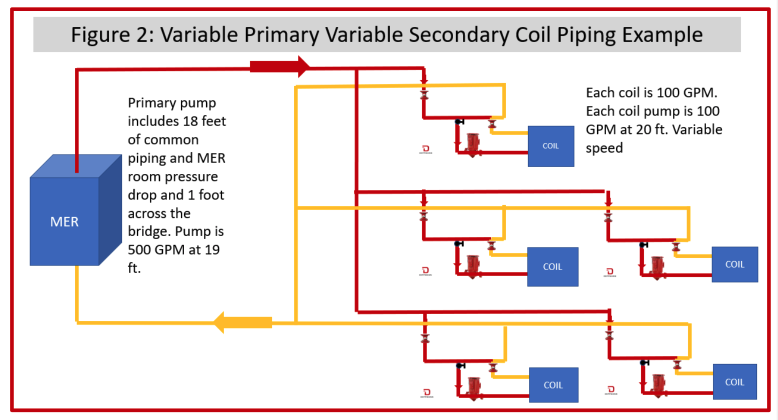

Variable Primary – Variable Secondary System with No Two-Way Control Valves

Look close at figure 2 and you will see no control valves. The coil air outlet temperature is controlled by varying the speed of the secondary pump. The primary pump speed may be controlled through a DP across the last bridge at a low-pressure drop of about a foot. The control may also simply be the design flow rate based on the number of boilers or chillers operating.

The pump energy used is the sum of the five variable speed coil pumps and the variable speed primary pump. Using a load profile of the B&G PLEV model, the annual pump operating cost in Michigan or Ohio is about $800.00.

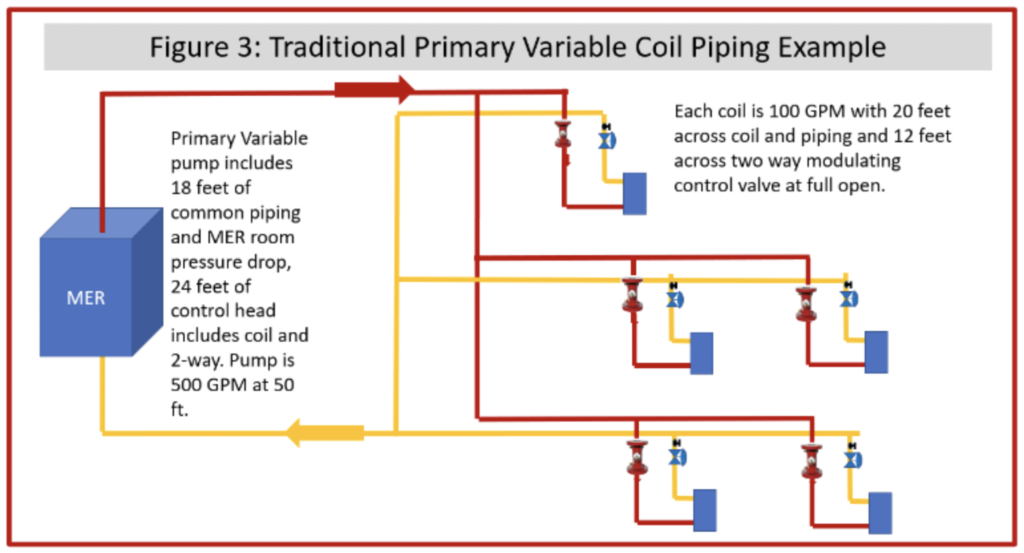

Variable Primary System with Modulating Two-Way Control Valves

The system above is a traditional primary variable system with five air handling units (AHU). The primary pump is 500 GPM at 50 feet and is variable speed. The control is monitoring a differential pressure (DP) sensor at the farthest zone and is set for 32 feet which is the farthest coil, coil piping, two-way control valve, and circuit setter. The control could also monitor the valve position in lieu of DP. This model mirrors the coil and trim pressure drop shown in the primary-secondary system above.

The pump energy used is the variable speed primary pump. Using a load profile of the B&G PLEV model, the annual pump operating cost in Michigan or Ohio is about $1,610.00.

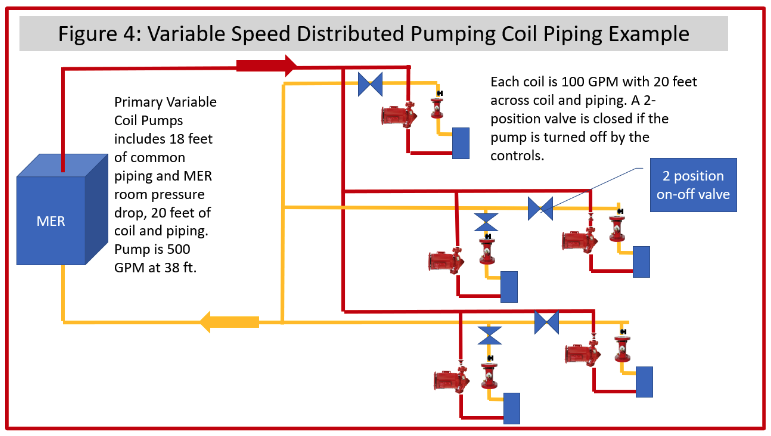

Variable Distributed Pumping System with On-Off Control Valves

The system above is a variable speed distributed pumping system with five air handling units (AHU). Each pump is 100 GPM at 38 feet and is variable speed. The drop from 50 feet is due to the elimination of the control valve. The BMS is controlling the outlet air temperature by varying the speed of the coil pump. There is a 2-position, on-off, valve at each pumping system. Since the coil pumps are also pumping the common pipe, there will be a pressure difference between the supply and return piping. That difference would cause flow in a coil, even when the pump is off. The 2-position valve prevents overheating or cooling.

The pump energy used is the variable speed coil pumps. Using a load profile of the B&G PLEV model, the annual pump operating cost in Michigan or Ohio is about $710.00.

First Cost Considerations

PRIMARY SECONDARY SYSTEM

In a primary secondary system, the first obvious cost saving is the elimination of control valves. The addition is changing the coil pumps to variable speed. This could be simply replacing the combination starter with a drive or by using a smart pump with the variable speed built in. The drive option would be close to a wash in price compared with the starter. The electrical and controls labor first cost would be about the same.

The primary pump drive could be set up to match the pump speed with the number of boilers operating.

VARIABLE PRIMARY VS. DISTRIBUTED VARIABLE SYSTEM

In a variable primary system, the first obvious cost saving is the elimination of control valves. The elimination of control valves is replaced with the addition of the on-off valves. The variable primary pump is replaced with five smaller variable speed coil pumps. This will be a significant first cost increase. The payback may extend out to over 10 years.

There is a possible hidden energy advantage. Most pumping energy analysis figures assume the coils are all operating at about the same load. What happens if the load varies from zone to zone? Assume the load profile among the five coils is 100%, 75%, 50%, 50%, 25%. The cost of operation drops by 50%. If the load profile is 100%, 90%, 90%, 70%, 70% the cost drops by 30%. This is because four of the 2-way valves are significantly throttled while one is wide open.

When talking to the “early adopter,” the variable speed vs. control valve discussion tends to favor the green choice. When talking to the “confident but comfortable,” the discussion stays with 2-way valves. The choices are yours. We hope this R. L. Deppmann Company Monday Morning Minutes helped you make a better decision.

Part One: Constant Speed 2-Way Control vs. Variable Speed Pumps for Heating and Cooling Coils (Part 1)